Advanced Electronic Testing Equipment for Tensile Strength Analysis and Measurement Solutions

The Role of Electronic Tensile Strength Testing Equipment in Material Science

In the evolving field of material science, the importance of accurate and reliable testing cannot be overstated. Among the various testing methods employed to assess material properties, tensile strength testing stands out as a critical procedure. This process evaluates how materials respond to tension, providing vital data on their strength, ductility, and overall structural integrity. To enhance the precision and efficiency of these tests, many organizations are turning to electronic tensile strength testing equipment.

Understanding Tensile Strength Testing

Tensile strength refers to the maximum amount of tensile (stretching) stress a material can withstand before failure. This property is particularly crucial in industries such as construction, automotive, aerospace, and manufacturing, where the integrity of materials can significantly impact safety and performance. Traditional tensile testing methods often relied on mechanical equipment, which, while still effective, had limitations in terms of accuracy and ease of use.

Electronic tensile strength testing equipment has revolutionized this process by incorporating advanced technology to produce more precise and repeatable results. These electronic devices not only automate much of the testing process but also provide real-time data analysis, which can be invaluable for research and quality control.

Benefits of Electronic Testing Equipment

1. Precision and Accuracy One of the primary advantages of electronic tensile strength testing machines is their ability to deliver precise measurements of force and elongation. With advanced sensors and sophisticated data acquisition systems, these machines can capture minute changes in material behavior under load, allowing for a comprehensive analysis of material properties.

2. User-Friendly Interfaces Modern electronic testing devices are designed with user-friendly interfaces that make it easier for technicians and engineers to set up tests and interpret results. Many units come equipped with touchscreen displays, intuitive menus, and guided workflows, reducing the likelihood of human error during testing.

electronic tensile strength testing equipment company

3. Data Management Electronic systems often come with software that facilitates data management. This allows users to store, analyze, and generate reports for test data seamlessly. Historical data can be archived and accessed for future reference, which is particularly beneficial for tracking material performance over time or complying with industry standards and regulations.

4. Speed and Efficiency Time is of the essence in material testing laboratories. Electronic tensile strength testing equipment typically enables faster testing cycles than their mechanical counterparts. This efficiency means that more tests can be conducted in a shorter period, enhancing productivity without sacrificing accuracy.

5. Versatility Electronic tensile testing machines are versatile and can be configured for a variety of materials, from metals and plastics to textiles and composites. Many machines also offer the capability to perform additional tests—such as compression, bending, or fatigue—using interchangeable fixtures, increasing their utility in a research or industrial setting.

Applications in Various Industries

The applications of electronic tensile strength testing equipment span various sectors. In the aerospace industry, for example, materials must meet stringent safety standards. Accurate tensile testing ensures that components can withstand the stresses experienced during flight. In construction, assessing the material properties of steel beams and concrete can prevent structural failures and ensure safety in buildings and bridges.

Similarly, the automotive industry relies on these tests to evaluate the durability of parts and materials that endure extreme conditions. The adoption of electronic tensile strength testing equipment has made it possible for manufacturers to innovate new materials with improved performance metrics, thus enhancing the safety and efficiency of vehicles on the road.

Conclusion

As industries continue to demand higher standards of quality and safety, the role of electronic tensile strength testing equipment becomes increasingly important. The combination of precision, efficiency, and versatility positions these machines as essential tools in the modern laboratory. For companies in material development and quality assurance, investing in advanced electronic testing equipment is not merely an option; it is a necessity. With these tools, organizations can ensure that they meet industry standards, enhance product quality, and drive innovation, positioning themselves for success in an ever-competitive market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

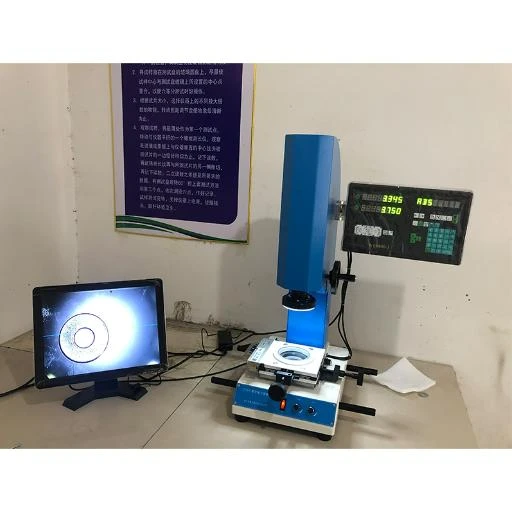

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy