machine to measure resistances factory

Understanding Resistance Measurement The Role of Machines in Factories

In the realm of electrical engineering and manufacturing, the accurate measurement of resistance is a critical component in ensuring the efficiency and reliability of products. Machines designed to measure resistances are essential tools in factories, where they serve a wide range of applications, from quality control to routine maintenance of electrical components. In this article, we will explore how these machines work, their significance in the manufacturing process, and the advancements in technology that enhance their capabilities.

The Basics of Resistance Measurement

Resistance, measured in ohms, is a fundamental electrical property that quantifies how strongly a material opposes the flow of electric current. Accurately measuring resistance is vital, as it directly affects the performance of electrical circuits. For instance, high resistance can lead to reduced current flow, which may impair the functioning of electronic devices, while low resistance might indicate short circuits or potential failures. Consequently, measuring devices that can provide precise resistance readings are crucial in ensuring the quality and safety of electrical components.

Types of Resistance Measuring Machines

There are various types of machines used to measure resistance in manufacturing settings. These include

1. Digital Multimeters (DMMs) One of the most commonly used devices, DMMs can measure voltage, current, and resistance, making them versatile tools on the factory floor. They provide quick readings displayed digitally, which enhances ease of use and reduces the likelihood of human error.

2. Ohmmeters Specifically designed for measuring resistance, ohmmeters can give precise readings of resistance in various components. They can operate independently or as part of a more extensive testing setup.

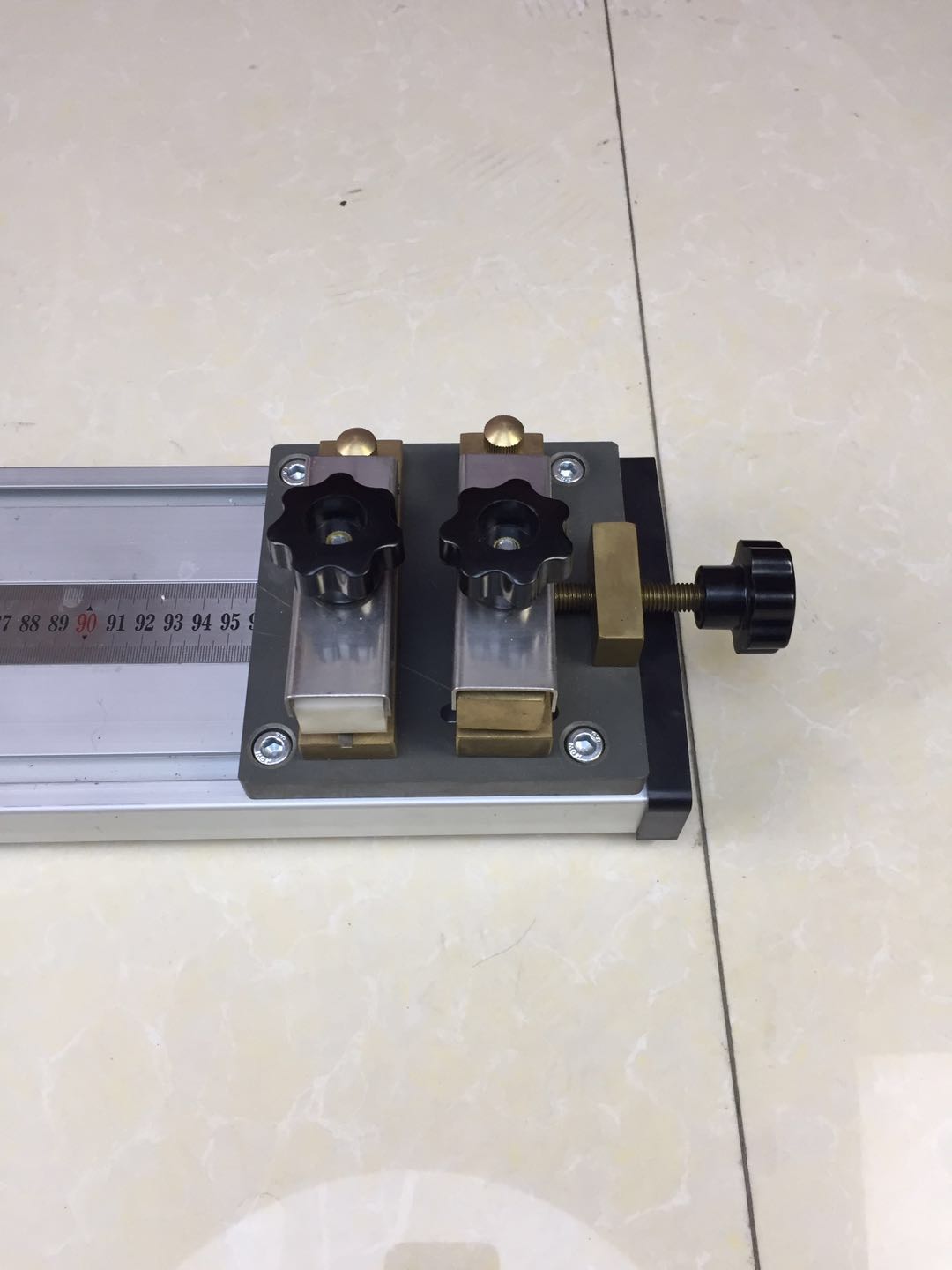

3. Four-Wire Measurement Systems This advanced method involves using four leads to connect to a resistor with a passing current. It helps eliminate the impact of lead and contact resistance, delivering extremely accurate results, often required in high-precision applications.

4. Resistance Bridge A more traditional technique, the resistance bridge is utilized mainly in laboratory settings for precise measurements. By balancing the bridge, one can measure unknown resistances with remarkable accuracy.

machine to measure resistances factory

The Importance in Manufacturing

In factory settings, machines to measure resistances play an instrumental role in several critical areas

- Quality control Regular resistance measurement is integral to quality control processes. Identifying resistive anomalies can help diagnose issues early, preventing defective products from reaching the market and ensuring compliance with safety standards.

- Preventive maintenance Monitoring the resistance of machinery and electrical components can indicate wear and tear and impending failures. By conducting routine checks, factories can perform preventive maintenance, thus avoiding costly downtimes and repairs.

- Research and development In the development of new materials and components, precise resistance measurement is essential to assess their properties and determine their potential applications.

Advancements in Technology

The world of resistance measurement machines has seen significant advancements. With the integration of digital technology, modern machines are now more accurate, user-friendly, and connected. Features such as data logging, remote monitoring, and integration with manufacturing execution systems (MES) enable factories to streamline processes and enhance overall productivity.

Moreover, advancements in materials science and sensor technology have led to the development of more sensitive and durable measuring devices. These innovations have made it possible to measure minute changes in resistance, opening doors to new applications in nano-engineering and other cutting-edge fields.

Conclusion

Machines designed to measure resistances are indispensable in the modern manufacturing landscape. Their ability to provide accurate and timely measurements ensures that electrical components function optimally, contributing to the overall quality and safety of products. As technology continues to evolve, the capabilities of these machines will expand, further enhancing their role in efficient manufacturing processes. In a world increasingly reliant on electronic devices, the importance of precise resistance measurement will only grow, underpinning innovation and reliability across various industries.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy