smoke density test machine suppliers

Smoke Density Test Machine Suppliers Ensuring Quality and Safety in Industrial Applications

In today’s industrial landscape, safety and quality assurance are paramount. One crucial aspect of ensuring these standards is the assessment of smoke density emitted from materials used in various applications, particularly in construction, automotive, and aerospace industries. Smoke density test machines play an essential role in measuring the amount of smoke produced by materials when subjected to fire or heat. As a result, the demand for smoke density test machine suppliers has significantly increased, prompting manufacturers to focus on developing reliable and efficient testing equipment.

Smoke density testing is vital for several reasons. Firstly, it helps to ascertain the level of toxicity of smoke generated by a material. In case of a fire, materials that produce dense, toxic smoke can pose a severe threat to life and health. By measuring smoke density, manufacturers can ensure that their products meet safety standards and regulations set by authorities, such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL). This compliance not only safeguards lives but also enhances the credibility of the manufacturers in the marketplace.

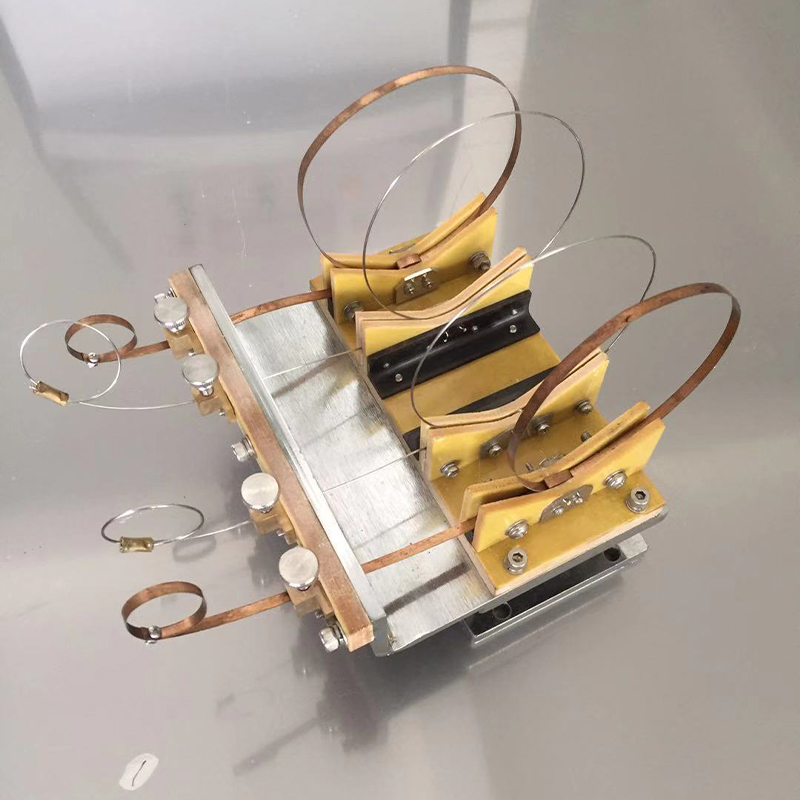

Suppliers of smoke density test machines offer a range of products tailored to meet the varied needs of different industries. These machines are designed to provide accurate and repeatable measurements, ensuring that manufacturers can trust the results. The most common types of smoke density test equipment include light transmission testers, smoke chambers, and specialized software for data analysis. Advanced models come equipped with automated features, enhancing usability and efficiency in both lab and on-site environments.

When selecting a supplier for smoke density test machines, it is vital to consider several key factors. Firstly, the reliability of the equipment is paramount. Suppliers should provide comprehensive specifications and performance guarantees, demonstrating that their machines meet or exceed industry standards. Secondly, customer support and after-sales service play a crucial role in ensuring that clients can maximize the potential of their equipment. Suppliers that offer training, maintenance, and prompt assistance can significantly affect the overall experience of the buyers.

smoke density test machine suppliers

Another critical factor is the technological advancements integrated into the smoke density test machines. Modern suppliers are increasingly adopting digital technologies, allowing for real-time data capture and analysis. Machines equipped with advanced sensors and IoT capabilities can transmit data to external devices, enabling remote monitoring and quicker decision-making processes. As industries continue to evolve, suppliers must stay ahead of technological trends to meet the demands of their clients effectively.

In addition to quality and technology, pricing also plays a significant role in supplier selection. While it is essential to invest in reliable equipment, suppliers should offer competitive pricing without compromising on quality. Transparent pricing strategies and detailed quotations can build trust between suppliers and clients.

Finally, sustainability is becoming increasingly important in the industrial sector. Suppliers are encouraged to develop smoke density test machines that not only provide reliable results but also adhere to eco-friendly practices. This may include using sustainable materials in their manufacturing processes or ensuring that their products consume less energy.

In conclusion, the role of smoke density test machine suppliers is integral to the safety and quality checks across various industries. By providing reliable, advanced, and competitively priced testing equipment, these suppliers contribute significantly to enhancing safety standards. As the demand continues to grow, those suppliers who integrate innovation and sustainability into their offerings will undoubtedly lead the market, ensuring a safer future for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy