Jan . 29, 2025 02:33

Back to list

projector measuring machine company

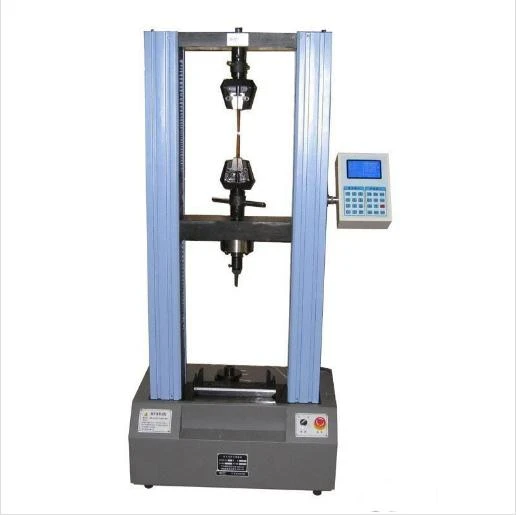

In the highly specialized world of material testing, the custom universal tensile tester machine stands as a pivotal innovation. These machines are essential for industries ranging from aerospace to construction, offering the capability to evaluate material tensile strength, elongation, and yield strength. A comprehensive understanding of these machines can bolster one’s authority and credibility within the manufacturing and engineering sectors.

The creation of a custom universal tensile tester machine requires a deep understanding of both the theoretical and practical aspects of material testing. Manufacturers often collaborate closely with the client’s engineering and research teams to create a tester that meets exact specifications. This partnership builds trust and ensures that the resulting machine aligns perfectly with the client’s needs, supporting their long-term operational goals. The expertise required to design and construct these custom machines establishes a manufacturer’s authority in the field of material testing. They need to cater to diverse industries, understanding the nuances of various materials and the environmental conditions they face. This expertise translates into a product that not only meets but often exceeds industry standards, providing clients with insight-driven solutions that foster greater reliability. Furthermore, the transparency in the manufacturing process of these custom machines is crucial in building trustworthiness. Leading manufacturers prioritize clear communication, from the initial consultation through to the final implementation, ensuring that clients are well-informed at each stage. This transparency helps in demystifying complex testing scenarios and provides clients with the confidence that their testing needs are being met with precision. Ultimately, the custom universal tensile tester machine plays a vital role in the advancement of materials technology. It empowers engineers and researchers with the tools necessary to perform rigorous testing and analysis, supporting innovation and enhancing the safety and performance of final products. The ongoing development in customization capabilities promises even more potential for these machines to address future material challenges. In conclusion, investing in a custom universal tensile tester machine is more than just purchasing equipment; it is an investment in quality assurance and innovation. It reflects a commitment to excellence and precision, elements that are key to maintaining authority and trust in highly competitive fields. As industries evolve, these machines will continue to adapt, meeting new challenges with expertise and reliability, thus cementing their place as an essential component of modern material testing.

The creation of a custom universal tensile tester machine requires a deep understanding of both the theoretical and practical aspects of material testing. Manufacturers often collaborate closely with the client’s engineering and research teams to create a tester that meets exact specifications. This partnership builds trust and ensures that the resulting machine aligns perfectly with the client’s needs, supporting their long-term operational goals. The expertise required to design and construct these custom machines establishes a manufacturer’s authority in the field of material testing. They need to cater to diverse industries, understanding the nuances of various materials and the environmental conditions they face. This expertise translates into a product that not only meets but often exceeds industry standards, providing clients with insight-driven solutions that foster greater reliability. Furthermore, the transparency in the manufacturing process of these custom machines is crucial in building trustworthiness. Leading manufacturers prioritize clear communication, from the initial consultation through to the final implementation, ensuring that clients are well-informed at each stage. This transparency helps in demystifying complex testing scenarios and provides clients with the confidence that their testing needs are being met with precision. Ultimately, the custom universal tensile tester machine plays a vital role in the advancement of materials technology. It empowers engineers and researchers with the tools necessary to perform rigorous testing and analysis, supporting innovation and enhancing the safety and performance of final products. The ongoing development in customization capabilities promises even more potential for these machines to address future material challenges. In conclusion, investing in a custom universal tensile tester machine is more than just purchasing equipment; it is an investment in quality assurance and innovation. It reflects a commitment to excellence and precision, elements that are key to maintaining authority and trust in highly competitive fields. As industries evolve, these machines will continue to adapt, meeting new challenges with expertise and reliability, thus cementing their place as an essential component of modern material testing.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy