cable winding test machine factory

The Evolution and Importance of Cable Winding Test Machines in Factories

In today's rapidly advancing technological landscape, the integrity and reliability of electrical cables are paramount. As industries increasingly rely on robust electrical systems, the necessity for rigorous testing of cables has never been greater. This is where cable winding test machines come into play, serving as a critical component in factories that manufacture electrical cables. These machines ensure that cables meet the industry standards necessary for safety, durability, and performance.

What is a Cable Winding Test Machine?

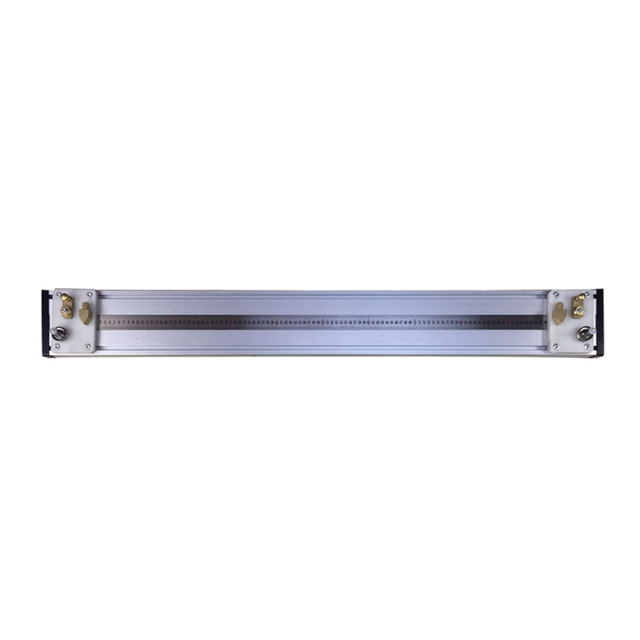

A cable winding test machine is designed to evaluate the winding quality and mechanical integrity of various types of cables. These machines perform a series of tests to simulate real-world conditions that cables may endure during use. This includes evaluating parameters such as tensile strength, flexibility, and winding tension. By thoroughly testing these aspects, manufacturers can identify any potential weaknesses in their products before they reach the market.

The Importance of Cable Testing

Cable testing is not merely an option but a necessity in modern manufacturing. Inappropriate cable handling can lead to catastrophic failures, resulting in significant safety hazards and financial losses. For instance, faulty cables could lead to electrical fires, equipment damage, or worse, personal injuries. Testing cables via winding test machines helps to assure customers of the cable's reliability and reduces the risk of post-sale failures.

Furthermore, many industries are now governed by strict regulations and standards, necessitating that products undergo comprehensive testing. For example, electrical installations in buildings, telecommunications, and power distribution systems must comply with standards set by organizations like IEC (International Electrotechnical Commission), UL (Underwriters Laboratories), and others. Compliance with these standards not only enhances the credibility of a manufacturer but also instills confidence in consumers.

cable winding test machine factory

The Technology Behind Cable Winding Test Machines

Modern cable winding test machines utilize advanced technology to conduct various tests efficiently and effectively. These machines come equipped with sophisticated sensors and software that allow for precise measurement of various parameters. For instance, the machines can measure the applied tension during the winding process, ensuring it does not exceed predefined limits that could compromise the cable’s integrity.

Moreover, many of these machines incorporate data logging features that enable manufacturers to track performance over time. This data can provide invaluable insights into production processes, helping manufacturers to pinpoint potential improvements and mitigate issues before they arise.

The Future of Cable Testing

The future of cable winding test machines looks promising, with an increasing trend towards automation and smart technology. As the Internet of Things (IoT) continues to integrate into manufacturing, cable winding test machines are expected to become more interconnected, allowing for real-time data analysis and remote monitoring. This innovation will enable manufacturers to respond swiftly to any irregularities detected during the testing phase, further enhancing product quality and safety.

Conclusion

In summary, cable winding test machines are indispensable in the manufacturing process of electrical cables. They play a crucial role in ensuring that cables are tested rigorously for quality and compliance with safety standards. As technology advances, these machines will continue to evolve, driving improvements in the efficiency, reliability, and safety of electrical systems globally. Therefore, investing in high-quality cable winding test machines is essential for manufacturers aiming to maintain a competitive edge and meet the growing demands of the market. The importance of these machines cannot be overstated, as they are integral to the safety and reliability of the electrical infrastructure that powers our world.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy