Understanding the Balance of Density in Manufacturing Processes and Its Impact on Efficiency

The Importance of Balance and Density in Manufacturing

In the ever-evolving landscape of manufacturing, the concepts of balance and density play crucial roles in optimizing processes, perfecting products, and enhancing overall efficiency. These two elements, while seemingly simple, have profound implications across various domains, from material science to supply chain management.

Understanding Balance and Density

Balance, in a manufacturing context, often refers to the equilibrium achieved in various facets of production—whether it be in the distribution of resources, weight distribution in product design, or balance between supply and demand. Achieving a proper balance helps manufacturers optimize workflows, maintain quality, and ensure timely delivery of products.

Density, on the other hand, refers to the mass of a substance per unit volume. In manufacturing, density influences several critical factors including strength, durability, and material choice. Different materials exhibit different densities, which ultimately impacts product performance and manufacturing processes. Understanding the relationship between density and weight becomes essential, particularly when designing products that require a balance between structure and functionality.

Applications in Manufacturing

1. Material Selection The choice of materials is fundamental to any manufacturing process. Engineers must carefully consider the density of materials to ensure that they meet specific product requirements. For example, in the aerospace industry, lightweight materials with a low density but high strength are essential for reducing fuel consumption and improving performance. In contrast, construction materials require higher density for durability and stability. By analyzing the balance between these properties, manufacturers can tailor their material selections to meet the desired specifications of their products.

science balance density manufacturers

2. Product Design and Development Manufacturing involves a delicate dance of balance during the design phase. Factors such as weight, ergonomics, and user experience must all be harmonized. Designers must ensure that products are not only appealing but also functional, and the density of materials plays a pivotal role in this process. An improperly balanced product may not perform as expected, leading to issues such as failure under load or ergonomic discomfort. Therefore, designers must use density metrics to guide their choices in product geometry and material properties.

3. Efficiency Optimization The concept of balance extends to the workflow and production processes within a manufacturing facility. Just as physical products need to be balanced, so too do the processes that create them. Effective workflow management ensures that resources are allocated efficiently—preventing bottlenecks and minimizing waste. Implementing techniques such as Just-In-Time (JIT) manufacturing can help maintain this balance, allowing manufacturers to respond flexibly to demand while reducing surplus inventory, which can be especially critical in a market that values speed and efficiency.

4. Quality Control Maintaining quality is another area where balance and density come into play. Manufacturers utilize density measurements as a quality control metric to ensure that materials and finished products meet industry standards. Any deviation in density may indicate a problem—whether it’s with raw material purity or a defect in the manufacturing process. Regular checks on density can help manufacturers maintain their quality assurance standards, ensuring consumer confidence and satisfaction.

5. Sustainability Initiatives Finally, the drive for sustainability in manufacturing also hinges on understanding balance and density. Manufacturers are under increasing pressure to reduce waste, minimize resource consumption, and lower their carbon footprints. By meticulously analyzing material densities, manufacturers can reduce excess material use without compromising quality. Balancing ecological impacts with production demands allows for innovative solutions that align with both business goals and environmental responsibility.

Conclusion

The concepts of balance and density are integral to the success of modern manufacturing. From material selection and product design to efficiency optimization and sustainability, understanding and leveraging these principles enables manufacturers to enhance their processes and products. In an industry that thrives on innovation and precision, a keen focus on balance and density can lead to significant competitive advantages. Manufacturers that prioritize these aspects in their operations will not only improve their efficiency but also contribute to the overall advancement of the manufacturing sector as a whole. In an increasingly complex world, achieving the right balance will be the key to sustainable growth and success in manufacturing.

-

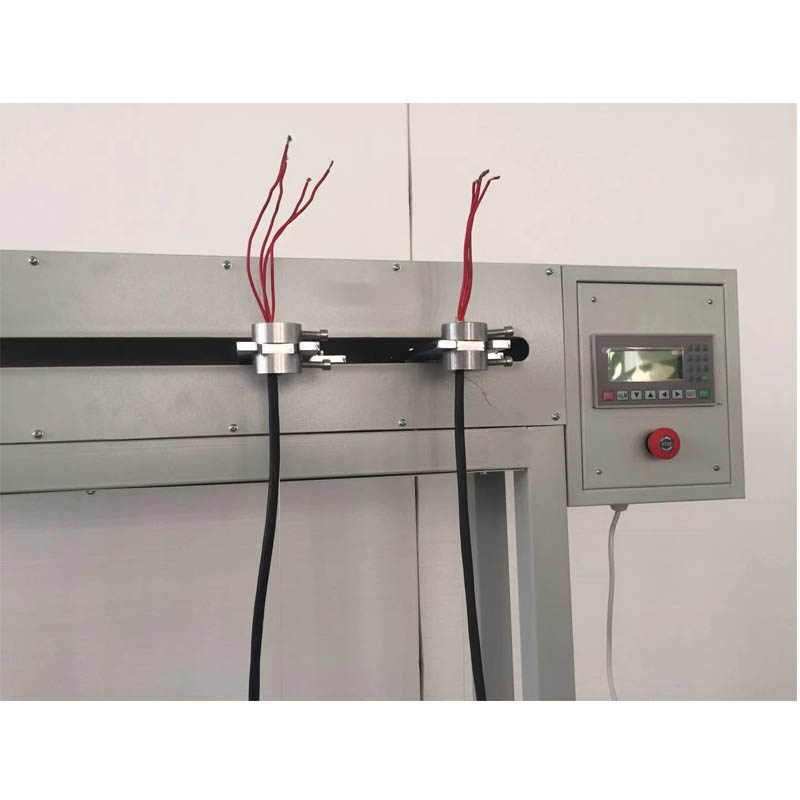

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy