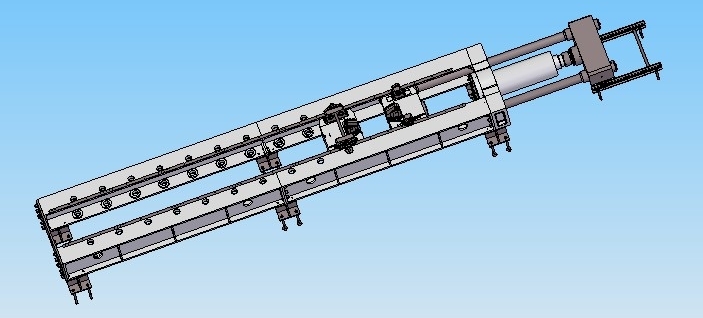

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Test Machine

ọja Apejuwe

TXWL-600 elekitiro-hydraulic servo petele tensile test machine adopts petele frame structure, nikan ọpá piston silinda ti o ni ilọpo meji ṣiṣẹ agbara idanwo, ati eto iṣakoso kọnputa mọ iṣakoso adaṣe ti ilana idanwo nipasẹ ṣiṣakoso àtọwọdá servo ati awọn paati miiran, idanwo naa A gba data ni deede nipasẹ sensọ fifuye ati gbigbe si kọnputa, eto naa ṣe itupalẹ laifọwọyi, awọn ilana ati tọju awọn abajade idanwo, ati pe itẹwe le tẹjade ijabọ idanwo ti o nilo taara. Ẹrọ yii jẹ lilo ni akọkọ fun idanwo fifẹ ti okun waya irin, jẹ iṣelọpọ igbalode ti iwadii imọ-jinlẹ ati ẹkọ ati awọn ile-iṣẹ miiran lati pade awọn ibeere ti ohun elo idanwo to peye.

Apejuwe ẹrọ

1.Gbalejo eto

Apakan ẹrọ akọkọ jẹ akọkọ ti fireemu ẹrọ akọkọ, ijoko silinda epo, silinda epo, ina gbigbe, iwaju ati ijoko ẹhin ati sensọ fifuye. O le ṣe idanwo fifẹ pẹlu fifuye ti o pọju ti 600kN lori apẹẹrẹ.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Agbegbe idanwo naa ni ipese pẹlu ideri aabo, eyiti o le daabobo aabo aabo awọn oṣiṣẹ idanwo daradara.

2.Epo orisun eto

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Electrical Section

Iṣakoso itanna ti wa ni idayatọ ni agbegbe iṣẹ idanwo, ati pe nronu iṣẹ ti a ṣe apẹrẹ pataki kan wa lati jẹ ki gbogbo iru awọn iṣẹ ṣiṣe di mimọ ni iwo kan. Awọn paati ina mọnamọna jẹ ami iyasọtọ olokiki agbaye, pẹlu iṣẹ iduroṣinṣin ati didara igbẹkẹle.

Eto Software:

(1) Da lori ẹrọ ṣiṣe Windows XP pẹlu awọn iṣẹ ṣiṣe siseto, iṣakoso agbara idanwo iwọn-dogba, iṣakoso iṣipopada iwọn-dogba, idaduro agbara idanwo, idaduro gbigbe ati awọn ipo idanwo miiran le ni idapo ni ifẹ lati pade awọn ibeere ti awọn ọna idanwo pupọ. si iye ti o pọju, ati lati mọ awọn ifihan data orisirisi, iyaworan yiya, ṣiṣe data, ibi ipamọ ati awọn iṣẹ titẹ sita ti o nilo fun idanwo naa.

(2) Fi ami ifihan iṣakoso ranṣẹ si àtọwọdá servo nipasẹ kọnputa lati ṣakoso ṣiṣi ati itọsọna ti àtọwọdá servo, nitorinaa ṣiṣakoso ṣiṣan sinu silinda, ati mimọ iṣakoso ti agbara idanwo iwọn-dogba, iṣipopada iwọn-dogba, bbl .

(3) Ni ipese pẹlu awọn iyipo iṣakoso lupu meji pipade ti agbara idanwo ati gbigbe.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Ni wiwo akọkọ ni gbogbo awọn iṣẹ ti iṣẹ ojoojumọ ti idanwo naa, gẹgẹbi titẹsi alaye ayẹwo, yiyan apẹẹrẹ, iyaworan ti tẹ, ifihan data, ṣiṣe data, itupalẹ data, iṣẹ idanwo, ati bẹbẹ lọ. sare.

(6) Awọn data le ṣejade si itẹwe lati tẹ ijabọ idanwo naa.

(7) Isakoso iṣakoso eto, awọn eto eto gbogbo wa ni sisi si awọn olumulo iwé, ni idaniloju irọrun ati igbẹkẹle ti eto naa.

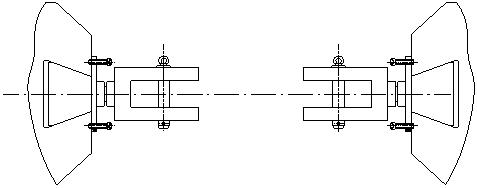

4.Test Awọn ẹya ẹrọ

Ni ipese pẹlu awọn ẹya ẹrọ idanwo okun waya (wo isalẹ) ati awọn ẹya ẹrọ miiran ti ṣelọpọ ni ibamu si boṣewa ti olumulo pese tabi awọn ibeere fifẹ ti apẹẹrẹ.

5.Safety Protection Devices

(1) Idaabobo apọju nigbati agbara idanwo kọja 2% si 5% ti agbara idanwo ti o pọju tabi iye ṣeto.

(2) Idabobo ikọlu nigbati piston ba lọ si ipo opin.

(3) Pẹlu iwọn otutu epo, ipele omi ati idaabobo idaabobo epo ati awọn ẹrọ itọkasi.

(4) Aaye idanwo naa ni ideri aabo lati ṣe idiwọ ayẹwo lati fifọ ati ja bo jade.

(5) Nigbati pajawiri ba waye, tẹ bọtini idaduro pajawiri lori minisita iṣakoso taara

Imọ paramita

1.O pọju igbeyewo agbara: 600kN

Iwọn wiwọn agbara 2.Test: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensile igbeyewo aaye (laisi piston ọpọlọ): 20mm ~ 12000mm

5.Piston ọpọlọ: 1000mm

6.Maximum ṣiṣẹ iyara ti piston: 100 mm / min

7.Deformation extensometer išedede: 0.01mm

8.Iwọn ti ẹrọ akọkọ (mm): 16000 (L) x 1300 (W) x 1000 (H) (laisi ideri aabo)