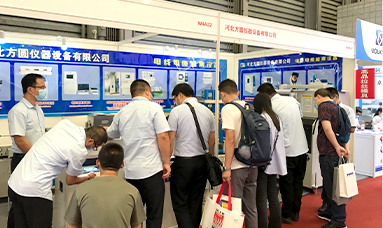

optical coordinate measuring machine factories

The Evolution and Significance of Optical Coordinate Measuring Machines in Manufacturing

In today's fast-paced manufacturing environment, precision and accuracy are paramount. Optical Coordinate Measuring Machines (CMMs) have emerged as essential tools in ensuring that manufacturing processes adhere to strict tolerances and specifications. These advanced measuring systems utilize optical technologies, such as laser scanning and high-resolution cameras, to capture detailed 3D measurements of components and assemblies.

Understanding Optical CMMs

Optical CMMs operate by using light waves to determine the coordinates of points on a surface. Unlike traditional mechanical CMMs, which rely on physical probes that touch the object being measured, optical CMMs employ non-contact methods. This advantage not only minimizes the risk of damaging delicate components but also improves the overall speed of measurement. In industries where delicate components are common, such as electronics and aerospace, this technology is not only beneficial but often vital.

The basic principle of optical CMMs lies in triangulation, where the machine calculates distances based on the angles of light beams and the resulting reflections. High-resolution images are captured and processed through sophisticated software to provide accurate measurements. The ability to quickly measure complex geometries and surfaces is revolutionizing the way manufacturers approach quality control and assurance.

Advantages of Optical CMMs

1. Non-contact Measurement As mentioned earlier, optical CMMs do not require physical contact with the object, reducing the risk of surface damage. This is particularly important in the manufacturing of sensitive materials, such as plastics and thin metals.

2. Speed and Efficiency Optical CMMs can collect data at a significantly faster rate than their mechanical counterparts. The rapid acquisition of measurement data allows manufacturers to streamline their workflows and reduce downtime.

3. Higher Accuracy Given the advancements in optical technology and specialized software algorithms, these machines provide superior accuracy. They are capable of capturing minute details that might be missed with traditional measurement tools.

Applications in Various Industries

optical coordinate measuring machine factories

The versatility of optical CMMs enables their use across multiple sectors

- Aerospace In the aerospace industry, precision is critical. Optical CMMs are used to measure the complex geometries of aircraft components, ensuring that every part adheres to rigorous safety standards.

- Automotive Automotive manufacturers employ optical CMMs for quality control of parts and assemblies. The technology helps in identifying defective components early in the production process, reducing waste and improving overall quality.

- Electronics The electronics sector relies heavily on optical CMMs to measure tiny components with high precision. The non-contact nature of these machines allows for the accurate testing of delicate circuit boards and chips.

- Medical Devices In the production of medical devices, maintaining strict tolerances is crucial for functionality and patient safety. Optical CMMs are employed to verify that products meet necessary regulatory standards.

Future Trends in Optical CMM Technology

As technology continues to evolve, the capabilities of optical CMMs are expected to expand further. Innovations such as artificial intelligence and machine learning are being integrated into measurement software, allowing for more intelligent data analysis. This will enhance the ability to predict potential manufacturing issues before they arise.

Additionally, the growing trend towards automation in manufacturing processes will likely lead to the increased use of optical CMMs in automated inspection systems. By integrating these machines into robotic systems, manufacturers can achieve unprecedented levels of efficiency and accuracy in quality control.

Conclusion

Optical Coordinate Measuring Machines are shaping the future of precision measurement in manufacturing. Their non-contact nature, speed, and accuracy make them invaluable tools across various industries. As technology continues to advance, the role of optical CMMs will become even more significant, providing manufacturers with the means to produce high-quality products that meet the demands of an ever-evolving marketplace. In the quest for precision and efficiency, optical CMMs stand at the forefront, ensuring that the manufacturing processes of tomorrow are better than ever before.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy