resistance measurement fixture factory

Understanding Resistance Measurement Fixture Factories

The realm of electrical components and measurement technology is vast and intricate, with precision and accuracy being of utmost importance. Among the various tools utilized in this field, resistance measurement fixtures play a pivotal role in the characterization and testing of electronic devices. This article will delve into the significance of resistance measurement fixture factories, highlighting their functions, processes, and impact on the electronics industry.

What Are Resistance Measurement Fixtures?

Resistance measurement fixtures are specialized devices designed to connect electrical components or circuits to testing instruments. They provide a stable and repeatable connection that ensures accurate resistance measurements. These fixtures are essential for manufacturers and engineers who need to verify the performance and reliability of their products.

Resistance measurement is critical in assessing the quality and functionality of components such as resistors, inductors, capacitors, and integrated circuits. Accurate measurements ensure that these components meet specifications, thus preventing failures in end-use applications.

The Role of Resistance Measurement Fixture Factories

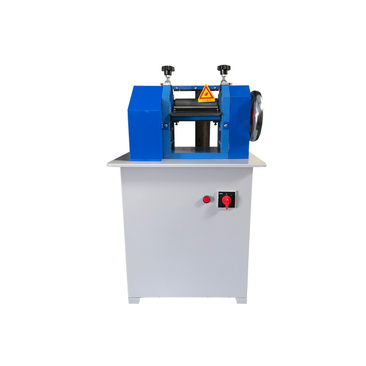

Resistance measurement fixture factories are specialized manufacturing units dedicated to producing these essential measurement tools. The factories are equipped with advanced machinery and technology to design, fabricate, and assemble high-quality fixtures tailored to specific measurement needs. The production process typically involves the following steps

1. Design and Prototyping The first stage often involves collaboration with engineers and customers to identify specific requirements. Using computer-aided design (CAD) software, prototypes are created to ensure that the fixture will perform effectively under various testing conditions.

2. Fabrication Once the design is finalized, the fabrication process begins. This may include cutting, machining, and assembling various materials, such as aluminum, stainless steel, and plastics, depending on the application of the fixtures. Factories may also employ automated processes to enhance precision and efficiency.

resistance measurement fixture factory

3. Testing and Quality Control After fabrication, each fixture undergoes rigorous testing to ensure it meets the necessary specifications. This step is crucial, as any deficiencies in the fixture could lead to inaccurate measurements, affecting the overall quality of the electronic components being tested.

4. Customization Many manufacturers require customized solutions. Resistance measurement fixture factories offer modifications to standard designs, ensuring that they meet the unique specifications and challenges posed by different electronic components.

Impact on the Electronics Industry

The significance of resistance measurement fixture factories extends beyond the manufacturing floor. They play a critical role in the broader electronics industry by

1. Enhancing Product Quality By providing reliable and accurate measurement tools, these factories help ensure the quality and performance of electronic components. This contributes to the overall reliability of consumer and industrial electronics.

2. Facilitating Innovation With accurate measurement tools, engineers can push the boundaries of technology, designing more sophisticated components with higher performance and efficiency.

3. Reducing Costs and Time Efficient manufacturing processes help reduce lead times and costs for electronic manufacturers, allowing for faster product development cycles without compromising on quality.

Conclusion

Resistance measurement fixture factories are integral to the production and testing of electronic components. Their ability to provide precise, reliable measurement tools directly influences the quality and performance of a wide array of devices that we rely on in our daily lives. As technology continues to evolve, the importance of these factories will only grow, emphasizing the need for ongoing improvements in measurement accuracy and manufacturing efficiency. By investing in robust measurement fixtures, manufacturers can ensure they remain at the forefront of innovation in the ever-competitive electronics market.

-

Redefining Electrical Safety: The Power of the High Insulation Resistance Measuring Instrument

NewsJun.05,2025

-

Precision Reimagined: The Digital Measurement Projector that Transforms Quality Control

NewsJun.05,2025

-

Precision in Every Test: The Conductor Resistance Constant Temperature Measurement Machine Sets a New Standard

NewsJun.05,2025

-

High-Voltage Assurance: The Cable Spark Tester That Guarantees Insulation Integrity

NewsJun.05,2025

-

Engineered for Excellence: The Computer Control Electronic Tensile Tester That Defines Material Strength

NewsJun.05,2025

-

Endurance in Every Curve: Flexible Cable Flexing Test Equipment Leads the Way

NewsJun.05,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy