Top Companies for Fabric Tensile Strength Testing Equipment and Solutions

Understanding Tensile Strength Testing in the Textile Industry

In the realm of the textile industry, ensuring the durability and performance of fabrics is paramount. One of the key aspects of this assessment is tensile strength testing, which measures the maximum amount of tensile (stretching) force that a fabric can withstand before failure. This testing is critical for manufacturers, designers, and quality control experts as it provides invaluable insights into the fabric's strength, usability, and overall quality.

Tensile strength testing involves applying a controlled force to a fabric sample until it deforms or ruptures. The results of these tests are essential for determining how fabrics will perform in real-world applications, whether in clothing, upholstery, or industrial uses. Various standardized methods, such as those defined by ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization), provide a framework for conducting these tests and ensuring consistency across different materials and manufacturers.

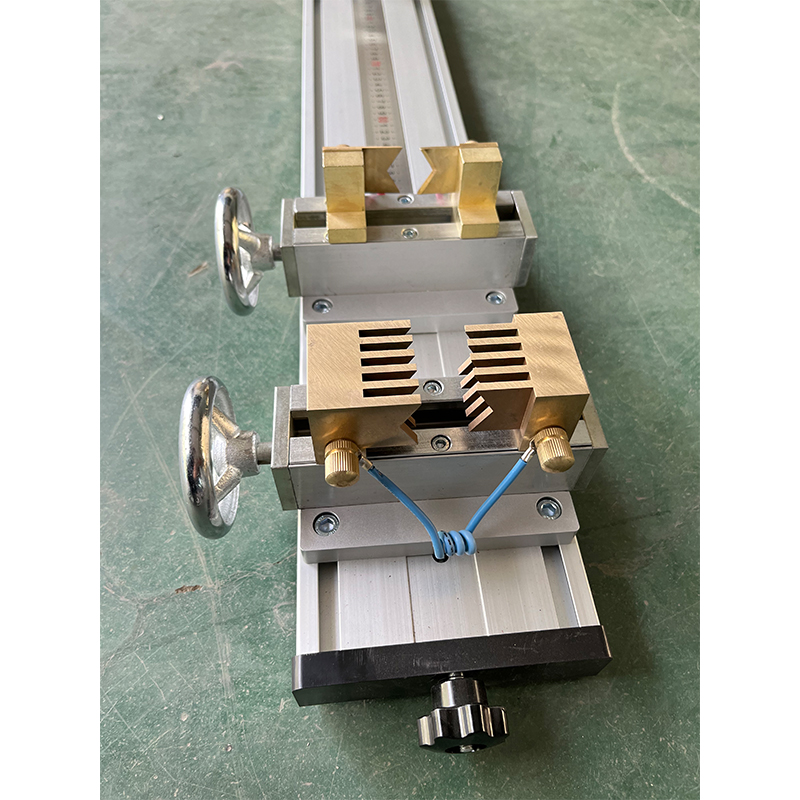

Several companies specialize in the development and manufacturing of tensile strength testing equipment for the textile industry. These companies offer a variety of machines and testing solutions designed to accommodate different fabric types and sizes. For instance, some testers are designed specifically for woven fabrics, while others cater to knits or non-woven materials. Advanced testing machines often come equipped with features such as digital displays, data logging capabilities, and the ability to perform multiple tests simultaneously, streamlining the quality assurance process.

tensile strength of fabric tester companies

Leading companies in this sector include those that produce universal testing machines, which not only test tensile strength but can also perform other mechanical testing, such as compression, bending, and shear tests. These versatile machines are a valuable asset in research and development settings and production facilities alike. Companies like Instron, ZwickRoell, and Tinius Olsen have made significant contributions to the field by continuously innovating their equipment to integrate advanced technologies such as automation and software analytics.

Moreover, the importance of accurate tensile strength testing transcends the confines of the lab. Retailers and consumers are becoming increasingly aware of the significance of fabric quality. With the rise of e-commerce and online shopping, customers value detailed specifications and quality assurances. Therefore, companies that invest in state-of-the-art tensile strength testing not only enhance their reputation but also meet consumer demand for high-quality, durable products.

As sustainability becomes a focal point in the textile industry, the relevance of tensile strength testing grows even more critical. Fabrics with lower tensile strength may lead to more frequent product replacements, contributing to waste and environmental issues. By choosing the right fabric based on robust test results, companies can minimize their ecological footprint while maximizing performance.

In conclusion, tensile strength testing is an indispensable process within the textile industry. Companies specializing in this testing provide essential tools that help manufacturers ensure their products meet high standards of quality and performance. The evolution of testing equipment and methods will continue to play a crucial role in shaping the future of textile manufacturing, allowing for innovations that prioritize durability, sustainability, and consumer satisfaction.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy