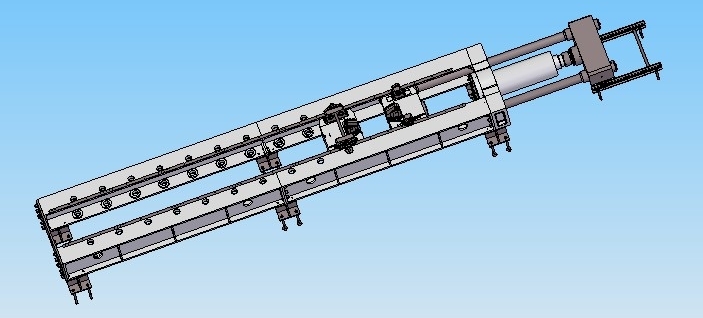

TXWL-600電液伺服臥式拉力試驗機

產品描述

TXWL-600電液伺服臥式拉力試驗機採用水平框架結構,單桿雙作用活塞缸施加試驗力,電腦控制系統透過控制伺服閥等部件實現試驗過程的自動控制,試驗載荷感測器準確採集數據並傳輸至計算機,系統自動分析、處理和儲存測試結果,印表機可直接列印所需的測試報告。本機主要用於鋼絲繩的拉力試驗,是滿足現代化生產、科學研究教學等產業需求的理想試驗設備。

機器描述

1.主機系統

主機部分主要由主機架、油缸座、油缸、移動橫樑、前後卡盤座及載重感測器等組成。可對樣品進行最大載重600kN的拉伸試驗。

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

測試區域設有防護罩,可有效保護測試人員的安全。

2.油源系統

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.電氣部分

電氣控制佈置在試驗操作區內,有專門設計的操作面板,使各種操作一目了然。電器元件皆採用國際知名品牌,性能穩定,品質可靠。

軟體系統:

(1)基於Windows XP操作平台,具有可程式功能,可任意組合等速率試驗力控制、等速率位移控制、試驗力保持、位移保持等多種試驗模式,滿足各種試驗方法的要求最大限度地實現試驗所需的各種數據顯示、曲線繪製、數據處理、儲存和列印功能。

(2)透過電腦向伺服閥發送控制訊號,控制伺服閥的開度與方向,進而控制進入油缸的流量,以實現等率試驗力、等率位移等的控制。

(3) 設有試驗力、位移兩個閉環控制迴路。

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5)主介面具有試驗日常操作的全部功能,如樣品資訊輸入、樣品選擇、曲線繪製、資料顯示、資料處理、資料分析、試驗操作等,試驗操作簡單、易操作。

(6)數據可輸出至印表機,列印測試報告。

(7)系統分級管理,系統參數全部對專家使用者開放,保證了系統的彈性與可靠性。

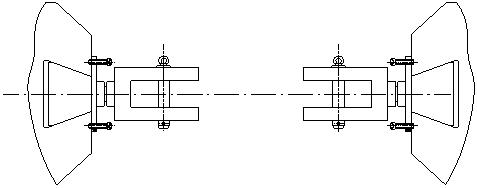

4.測試配件

配備鋼絲繩試驗附件(見下圖)等附件依使用者提供的標準或樣品的拉力要求製造。

5.安全保護裝置

(1)試驗力超過最大試驗力或設定值的2%~5%時過載保護。

(2)活塞運動到極限位置時的行程保護。

(3)具有油溫、液位、油阻保護及指示裝置。

(4)試驗空間有防護罩,防止樣本破裂掉落。

(5)發生緊急狀況時,直接按下控制櫃上的急停按鈕

技術參數

1.最大試驗力:600kN

2.試驗力測量範圍:10kN~600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.拉伸試驗空間(不含活塞行程):20mm~12000mm

5.活塞行程:1000mm

6.活塞最大工作速度:100毫米/分鐘

7.變形引伸計精度:0.01mm

8.主機尺寸(mm):16000(長)×1300(寬)×1000(高)(不含防護罩)