cable bending test machine supplier

The Evolution and Importance of Cable Bending Test Machines

In an era where technology is advancing rapidly, the need for high-quality components in electrical and electronic devices has never been more critical. Among these components, cables play a vital role in ensuring the efficiency and reliability of devices. To assess the durability and performance of these cables, manufacturers rely on cable bending test machines. This article will explore the significance of cable bending test machines, their evolution, and their impact on the industry.

Understanding Cable Bending Test Machines

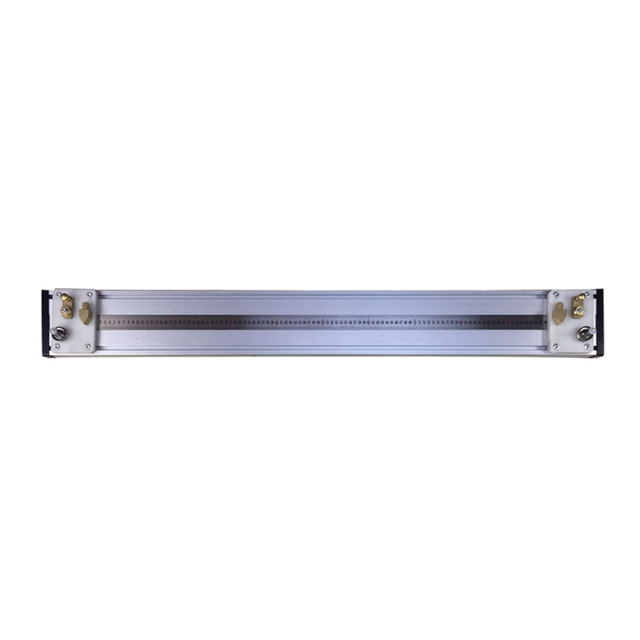

Cable bending test machines are specialized devices designed to evaluate the mechanical properties of cables, particularly their resistance to bending and flexing. These machines simulate the real-world conditions that cables endure when they are installed in electronic devices or during transportation. By subjecting cables to repeated bending cycles, manufacturers can assess their structural integrity, flexibility, and longevity.

The testing procedure typically involves clamping one end of the cable while the other end is bent to a specific angle and then returned to its original position. This process is repeated numerous times to mimic the stresses that cables experience in everyday use. The results from these tests help manufacturers determine which cables meet industry standards and how well they perform under different conditions.

Evolution of Cable Bending Test Machines

The development of cable bending test machines has come a long way since their inception. Early machines were often manual and required significant human intervention to operate. As technology progressed, manufacturers began to integrate automation into these systems, allowing for more precise and consistent testing.

Today, modern cable bending test machines feature advanced automation capabilities, including programmable testing cycles, real-time data monitoring, and sophisticated software analyses. These enhancements provide engineers with valuable insights into cable performance, ensuring that products meet or exceed industry standards. Furthermore, many test machines are designed to accommodate a variety of cable types, from simple power cords to complex multi-conductor cables, increasing their versatility and utility in the manufacturing process.

The Importance of Cable Bending Tests

Conducting cable bending tests is essential for several reasons

cable bending test machine supplier

1. Safety Cables are often integrated into systems that carry electricity, making safety a top priority. By rigorously testing the flexibility and durability of cables, manufacturers can prevent failures that might lead to short-circuits, electrical fires, or even electrocution.

2. Quality Assurance In a competitive marketplace, the quality of products sets manufacturers apart. Testing cables for their bending resistance ensures they can withstand everyday wear and tear, resulting in a more reliable product that enhances brand reputation.

3. Compliance with Regulations Many industries have stringent regulations regarding cable performance. Cable bending tests help manufacturers demonstrate compliance with these standards, making it easier to achieve certifications and gain access to new markets.

4. Cost Efficiency By identifying weaknesses and potential failure points in cables before they hit the market, manufacturers can reduce costs associated with warranty claims and product recalls. This proactive approach ultimately saves money and preserves consumer trust.

Choosing the Right Supplier

When selecting a cable bending test machine supplier, it’s crucial to consider experience, technology, and customer support. A reputable supplier will have a proven track record of producing high-quality machines that meet industry standards. Additionally, they should offer comprehensive technical support and training to ensure that customers can operate their test machines effectively.

As the demand for reliable cables continues to rise, the role of cable bending test machines in ensuring quality and safety will only grow. By investing in advanced testing technology, manufacturers can deliver superior products that meet the evolving needs of consumers and industry standards.

Conclusion

Cable bending test machines are indispensable tools in the quality assurance process of cable manufacturing. With their evolution towards automation and advanced testing capabilities, these machines provide valuable insights into the durability and performance of cables. The importance of conducting thorough cable bending tests cannot be overstated, as they contribute to safety, quality assurance, compliance, and cost efficiency. As the industry advances, partnering with a reliable supplier of cable bending test machines will be essential for manufacturers aiming for excellence in their products.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy