China's Advanced Tensile Testing Machines for Quality Materials Analysis and Performance Evaluation

The Importance of Tensile Testing Machines in China

Tensile testing machines play a crucial role in the field of materials science and engineering, particularly in China, where rapid industrialization and technological advancement demand rigorous quality control and experimentation. These machines are fundamental in evaluating the mechanical properties of various materials, including metals, plastics, and composites, by measuring their response to tensile stress. This article explores the significance, types, applications, and future outlook of tensile testing machines in the Chinese context.

Understanding Tensile Testing Machines

At its core, a tensile testing machine is a device that pulls a material specimen apart to understand its mechanical properties, such as tensile strength, yield strength, elongation, and elastic modulus. The process typically involves preparing a standardized specimen, which is then subjected to controlled tension until failure. The data generated from this process are invaluable for engineers and manufacturers who need to ensure that materials meet specific performance criteria.

Types of Tensile Testing Machines

In China, various types of tensile testing machines are available, ranging from manual to fully automated systems. Manual machines are often used in educational settings or small laboratories, while computerized models can provide more sophisticated testing and analysis capabilities. Servo-controlled tensile testing machines are particularly popular due to their precision and ability to carry out complex test protocols. Additionally, there are multi-purpose machines that can conduct not only tensile tests but also compression, bending, and fatigue tests, making them versatile tools in quality assurance laboratories.

Applications in Various Industries

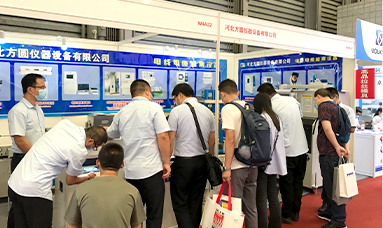

china tensile testing machine

Tensile testing machines are indispensable across a broad spectrum of industries in China. In the automotive sector, they are employed to test materials used in vehicle manufacturing, ensuring safety and performance standards. The construction industry relies on tensile testing for the evaluation of materials like steel and concrete, critical for structural integrity. Additionally, the aerospace industry utilizes these machines to ensure that materials can withstand the extreme conditions encountered during flight.

Furthermore, advancements in electronics have led to an increased need for tensile testing in the production of components for devices such as smartphones and laptops. As renewable energy technologies gain traction, tensile testing is also essential in evaluating materials used in wind turbines and solar panels. The diverse applications highlight the importance of tensile testing as a pillar of quality assurance in modern manufacturing processes.

Quality Control and Regulatory Compliance

As China continues to expand its manufacturing capabilities and export markets, the role of tensile testing machines in quality control cannot be overstated. Adhering to international standards, such as ASTM or ISO, ensures that products meet global safety and performance benchmarks. Companies that invest in reliable tensile testing machines gain a competitive advantage by reducing the likelihood of material failure, thereby enhancing product reliability and consumer trust.

The Future of Tensile Testing in China

Looking ahead, the future of tensile testing machines in China appears promising. The integration of technology, such as artificial intelligence and machine learning, is expected to enhance the accuracy and efficiency of testing processes. Remote monitoring and data analytics will allow for real-time assessment, enabling manufacturers to swiftly adapt to material behavior predictions.

In conclusion, tensile testing machines are integral to the operational fabric of numerous industries in China. As technology evolves and industrial demands increase, these machines will further establish their significance in ensuring quality and safety across various sectors. The ongoing development and adoption of advanced tensile testing technologies will not only bolster China's manufacturing capabilities but will also contribute to the global discourse on material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy