electrical insulation resistance tester factories

Electrical Insulation Resistance Tester Factories An Overview

In the contemporary landscape of electrical engineering, the importance of safety and reliability cannot be overstated. Among the various tools employed to ensure these attributes, an electrical insulation resistance tester (often abbreviated as insulation resistance tester) holds a pivotal role. These devices are designed to evaluate the integrity of electrical insulation in various components, from motors and transformers to cables and circuits. This article explores the significance of electrical insulation resistance tester factories, their operations, and the factors contributing to their relevance in today's electrical industry.

What is an Electrical Insulation Resistance Tester?

An electrical insulation resistance tester is a specialized instrument used to measure the resistance of electrical insulation materials. By applying a high voltage (usually in the range of 250V to 5000V) to the insulation, the tester assesses how well the insulation can prevent current leakage. The results are crucial for diagnosing problems in electrical equipment, ensuring compliance with safety standards, and determining whether maintenance or replacement procedures are necessary.

The Role of Factories

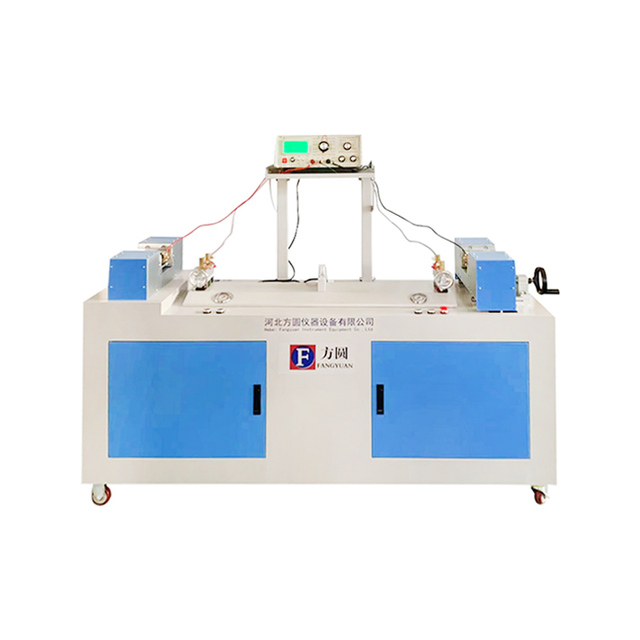

Electrical insulation resistance tester factories are instrumental in the design, manufacturing, and distribution of these critical devices. They employ a combination of advanced technology, skilled labor, and stringent quality control processes to produce reliable testers that meet global standards. The factories engage in various activities, including research and development (R&D), assembly, testing, and quality assurance.

Research and Development

R&D in insulation resistance testers focuses on enhancing accuracy, durability, and user-friendliness. Factories often collaborate with engineers and industry experts to innovate and improve upon existing designs. The goal is to create testers that not only adhere to international safety standards but also incorporate features tailored to specific applications, such as digital displays, automated testing cycles, and data logging capabilities.

Assembly and Production

The assembly of electrical insulation resistance testers involves a meticulous process where precision is paramount. Factories utilize advanced machinery for components like resistors, capacitors, and microprocessors. Skilled technicians assemble these components into a finished product, ensuring that every device meets rigorous specifications. Mass production techniques enable factories to offer competitive pricing without compromising quality.

electrical insulation resistance tester factories

Quality Control Measures

Quality inspectors play a crucial role in maintaining the integrity of the manufacturing process. Each tester undergoes a series of tests and inspections, including calibration, stress testing, and environmental simulations. These measures ensure that the testers can function reliably under varying conditions, from extreme temperatures to high humidity. Compliance with international standards, such as IEC and ANSI, is non-negotiable for reputable manufacturers.

Factors Contributing to the Demand for Insulation Resistance Testers

Several factors drive the demand for electrical insulation resistance testers and, consequently, the operations of their manufacturing factories

1. Safety Regulations Stringent safety regulations in sectors such as construction, manufacturing, and utilities necessitate regular insulation testing. Companies are compelled to invest in reliable testing equipment to comply with these regulations.

2. Aging Infrastructure Many industries are grappling with aging electrical infrastructures that require frequent evaluation. Insulation resistance testers help assess the condition of existing installations, ensuring they remain safe and functional.

3. Technological Advancements The rapid advancement of technology in electrical systems calls for updated testing methods. Factories that produce innovative testers with enhanced features are well-positioned to meet market demands.

4. Awareness of Electrical Safety Growing awareness and education regarding electrical safety among engineers and technicians have increased the usage of insulation resistance testers. This trend further stimulates growth in manufacturing capacities.

Conclusion

Electrical insulation resistance tester factories play a crucial role in the safety and reliability of electrical systems. By combining innovation, meticulous manufacturing processes, and robust quality control measures, these factories produce essential tools that help prevent electrical failures, reduce risks, and comply with safety regulations. As technology evolves and the demand for electrical safety grows, the importance of these factories will continue to be amplified in the industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy