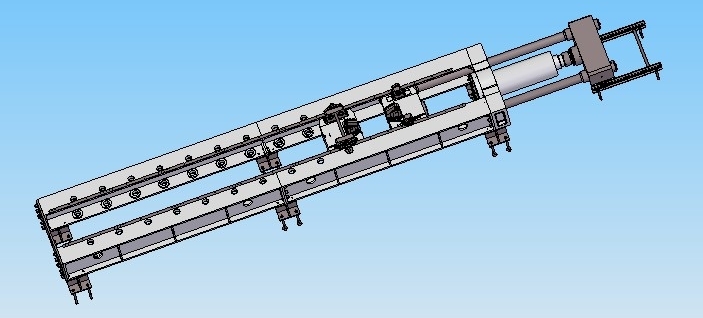

TXWL-600电液伺服卧式拉力试验机

产品描述

TXWL-600电液伺服卧式拉力试验机采用卧式框架结构,单杆双作用活塞缸施加试验力,计算机控制系统通过控制伺服阀等元件实现试验过程的自动控制,试验数据由荷重传感器准确采集并传输至计算机,系统自动分析、处理和存储试验结果,打印机可直接打印所需的试验报告。该机主要用于钢丝绳的拉伸试验,是满足现代化生产科研教学等行业要求的理想试验设备。

机器描述

1.主机系统

主机部分主要由主机架、油缸座、油缸、移动横梁、前后卡盘座、载荷传感器等组成,可对试样进行最大载荷600kN的拉伸试验。

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

测试区域设有防护罩,可有效保护测试人员的安全。

2.油源系统

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.电气部分

电气控制布置在试验操作区内,并有专门设计的操作面板,使各种操作一目了然。电气元件均采用国际知名品牌,性能稳定,质量可靠。

软件系统:

(1)基于具有可编程功能的Windows XP操作平台,可任意组合等速率试验力控制、等速率位移控制、试验力保持、位移保持等试验模式,最大限度满足各类试验方法的要求,并实现试验所需要的各种数据显示、曲线绘制、数据处理、储存和打印功能。

(2)通过计算机向伺服阀发出控制信号,控制伺服阀的开度和方向,从而控制进入油缸的流量,实现等率试验力、等率位移等的控制。

(3)设有试验力、位移两个闭环控制回路。

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5)主界面具有试验日常操作的全部功能,如样品信息录入、样品选择、曲线绘制、数据显示、数据处理、数据分析、试验操作等,试验操作简便、快捷。

(6)可将数据输出至打印机,打印测试报告。

(7)系统分级管理,系统参数全部对专家用户开放,保证了系统的灵活性和可靠性。

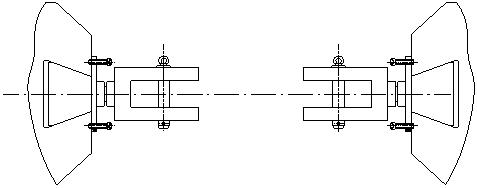

4.测试配件

配备的钢丝绳试验附件(见下文)及其他附件均根据用户提供的标准或试样拉力要求制造。

5.安全保护装置

(1)当试验力超过最大试验力或设定值的2%~5%时,进行过载保护。

(2)活塞运动到极限位置时的行程保护。

(3)具有油温、液位、油阻保护及指示装置。

(4)测试空间设有防护罩,防止样品破碎、掉落。

(5)发生紧急情况时,直接按控制柜上的急停按钮

技术参数

1.最大试验力:600kN

2、试验力测量范围:10kN~600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.拉伸试验空间(不含活塞行程):20mm~12000mm

5.活塞行程:1000mm

6.活塞最大工作速度:100mm/min

7.变形引伸计精度:0.01mm

8.主机尺寸(mm):16000(长)x1300(宽)x1000(高)(不含防护罩)