tensile testing machine factories

The Importance of Tensile Testing Machines in Material Science

Tensile testing machines play a crucial role in the field of material science and engineering. These machines are designed to determine how materials will react when subjected to tension, providing invaluable data regarding their tensile strength, elasticity, and overall durability. As industries seek to ensure the quality and reliability of their products, tensile testing machines have emerged as an essential tool for manufacturers worldwide.

Understanding Tensile Testing

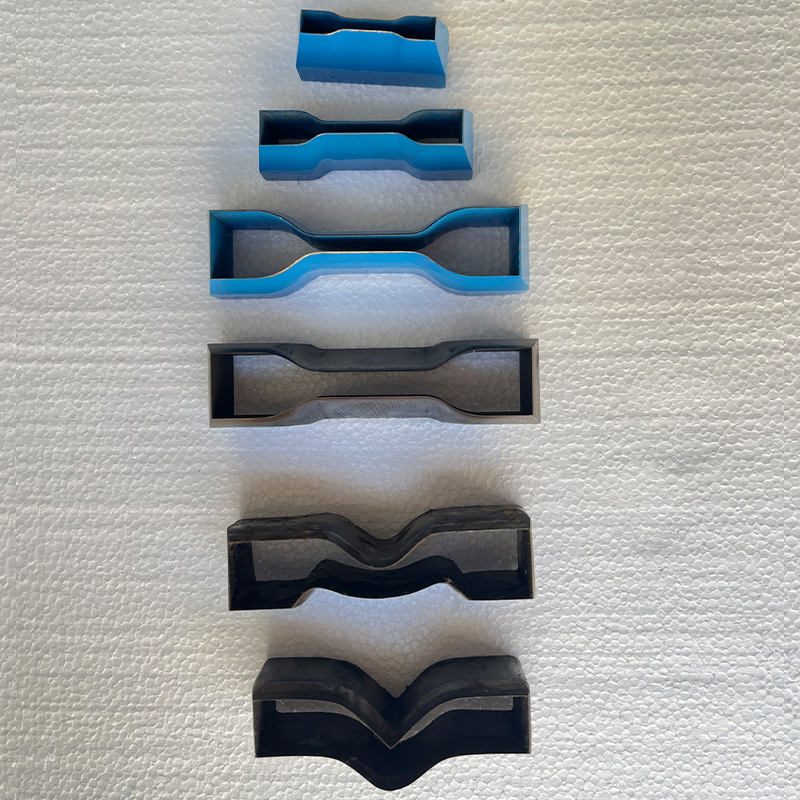

Tensile testing, also known as tension testing, involves applying a uniaxial force to a material until it breaks. The results of such testing yield a stress-strain curve, which illustrates how a material behaves under tension. Key parameters measured during this process include ultimate tensile strength (UTS), yield strength, elongation, and tensile modulus. The ability to accurately measure these parameters helps in predicting how a material will perform in real-life applications, making tensile testing machines invaluable for various industries.

Applications Across Industries

Tensile testing machines are utilized across a wide range of sectors, including construction, automotive, aerospace, and textiles. For example, in the construction industry, tensile tests help determine the strength of steel and other materials used in building structures. In the automotive sector, these tests assess the properties of materials used in vehicle components, ensuring safety and reliability. Aerospace industries rely on tensile testing to evaluate lightweight materials that need to withstand extreme conditions without failure. Even in textiles, tensile testing machines help assess the durability and quality of fabrics, greatly influencing garment construction and product longevity.

Key Features of Modern Tensile Testing Machines

tensile testing machine factories

Modern tensile testing machines are equipped with sophisticated technology that enhances their performance and accuracy. Many machines come with computer integration that allows for real-time monitoring and data analysis. This integration helps in generating precise stress-strain curves and provides visualizations that aid in interpreting results. Advanced software can automatically calculate important material properties, simplifying the testing process and reducing the likelihood of human error.

Additionally, manufacturers of tensile testing machines have started to innovate with features such as load cells for enhanced measurement sensitivity, extensometers for precise elongation tracking, and user-friendly interfaces that facilitate easier operation. Some machines are even capable of conducting tests at various temperatures and environmental conditions, which is essential for materials used in extreme environments.

Factors to Consider When Choosing a Tensile Testing Machine

When selecting a tensile testing machine, several factors warrant consideration. First and foremost is the range of materials that need to be tested. Different machines are designed for specific material types, ranging from metals and plastics to textiles and composites. Another vital consideration is the testing capacity in terms of maximum load and elongation, ensuring the machine can handle the expected materials.

Calibration and maintenance are also critical factors to keep in mind. Regular calibration ensures that the machine delivers accurate results, while proper maintenance prolongs its lifespan. Moreover, compatibility with third-party software or additional testing equipment may be necessary for organizations that require comprehensive testing solutions.

Conclusion

In conclusion, tensile testing machines are indispensable equipment in material testing and quality assurance. They empower manufacturers to understand material properties better, ensuring product reliability and safety across various industries. Advanced technology has significantly improved the capabilities of these machines, making them more accurate and user-friendly. As technology continues to evolve, the role of tensile testing machines will undoubtedly expand, further contributing to advancements in material science and engineering. Choosing the right tensile testing machine not only boosts efficiency and accuracy but also upholds the standards of safety and quality that modern industries demand. In an age where material integrity is paramount, investing in high-quality tensile testing equipment is not just a choice; it's a necessity for maintaining competitive edge and ensuring consumer trust.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy