Reliable Performance Testing with Advanced Aging Chamber Solutions

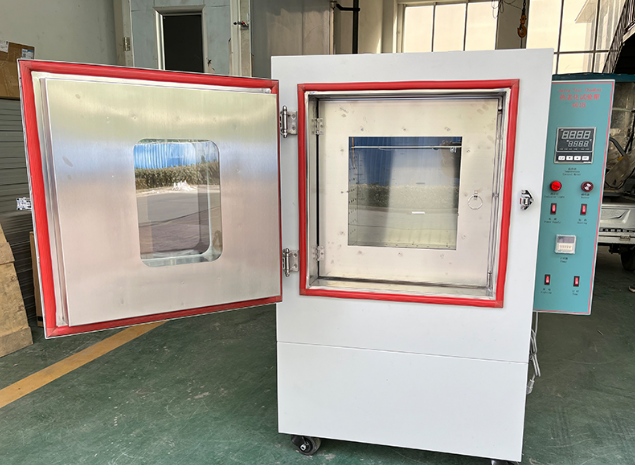

In industries where polymer materials, electrical insulation, and wire sheathing are used, product durability directly impacts safety and long-term performance. To ensure materials maintain their integrity under heat and environmental stress, advanced testing equipment is essential. Among these tools, the aging test chamber, the cable aging chamber, and the more versatile aging chamber stand out as indispensable solutions. These chambers are designed to replicate high-temperature, ventilated environments that simulate the natural wear and tear materials experience over time. By delivering accurate, repeatable, and standard-compliant results, they help manufacturers validate quality, extend product lifespans, and maintain compliance with global testing requirements.

Precision in Thermal Testing

Aging tests are not simply about subjecting materials to heat; they are about replicating real-life stress conditions in a controlled and measurable way. The aging test chamber is designed with advanced temperature controls, ensuring consistency throughout the test cycle. Unlike simple ovens, these chambers deliver precise uniformity thanks to their natural ventilation system and adjustable air outlets. This ensures that every material sample, whether a rubber specimen or a plastic sheath, is exposed to identical conditions. Such accuracy is essential for determining the actual thermal endurance of insulation components and other polymer-based materials. Moreover, compliance with standards like IEC 60811 demonstrates the reliability and industry recognition of these chambers. In sectors where safety margins are tight—such as aerospace, automotive, and telecommunications—confidence in the thermal testing process is invaluable.

Specialized Applications for Cables and Polymers

When it comes to wires and cables, testing durability is more than a performance matter; it is a safety necessity. The cable aging chamber was specifically developed to test insulation and sheath materials used in electrical wires, ensuring they can withstand prolonged exposure to heat without deterioration. Heat shrinkable sleeves, PVC insulation, and rubber coatings undergo aging tests to confirm their resistance to cracking, melting, or losing insulating capability. For manufacturers, this step is not optional but required to guarantee that their products meet electrical safety regulations and perform under challenging operating conditions. Beyond cables, the aging chamber also plays a significant role in industries working with plastics, elastomers, and other polymer-based materials. By simulating long-term exposure in a compressed timeframe, businesses can accelerate product development cycles while maintaining rigorous quality control.

Flexible Testing Configurations

Aging chambers are not one-size-fits-all. Different products demand varying test durations, temperature settings, and ventilation adjustments. Modern aging test chamber systems come with programmable controls, timers up to 200 hours, and adjustable ventilation ranging from 8 to 20 times per hour. This flexibility allows users to replicate diverse real-world conditions in a laboratory environment. The adjustable ventilation outlets, for example, enable technicians to fine-tune airflow for optimal thermal distribution, ensuring that heat stress impacts the material realistically. The chambers can also function as precision drying ovens, supporting drying, baking, or heat-treatment processes for multiple applications. This adaptability reduces the need for multiple machines and maximizes return on investment, making these chambers a cost-effective choice for manufacturers across industries.

Compliance, Safety, and Long-Term Value

Investing in an aging chamber is not merely a matter of acquiring a piece of equipment; it is about ensuring compliance, guaranteeing safety, and delivering products that stand the test of time. With built-in safety ventilation systems, users can rely on safe operation even during prolonged high-temperature testing. Compliance with international standards reassures businesses that their testing methods meet global expectations, which is crucial for export-oriented industries. The long-term value of a cable aging chamber lies not just in its immediate testing accuracy but also in its contribution to product reliability. When cables, polymers, or insulation materials pass rigorous thermal endurance tests, they bring confidence to end-users and safeguard reputations in competitive markets. Over time, the consistent performance of these chambers ensures that manufacturers minimize product failures, reduce warranty claims, and build stronger relationships with customers.

Aging Chamber FAQs

What is the purpose of an aging test chamber?

An aging test chamber is designed to simulate the effects of long-term environmental exposure, primarily through controlled heat and ventilation. By exposing materials to elevated temperatures in a uniform and repeatable way, manufacturers can determine how insulation, plastics, and other polymers will perform over time. This process is vital for quality assurance and safety validation.

How does a cable aging chamber differ from a standard chamber?

Ang cable aging chamber is tailored for testing the thermal endurance of electrical wire sheaths and insulation materials. While a standard aging chamber may test various polymers, the cable-specific design ensures compliance with electrical testing standards, providing results directly applicable to the cable and wiring industry. This specialization makes it indispensable for manufacturers in electrical and telecommunications fields.

What industries benefit most from aging chambers?

Industries such as automotive, aerospace, electronics, construction, and telecommunications frequently rely on aging test chamber solutions. These sectors require assurance that materials like rubber seals, insulation components, or plastic casings will withstand years of stress. By integrating aging tests into quality control, businesses reduce risks of product failure and enhance market trust.

What safety features are included in modern aging chambers?

Safety is built into the design of every aging chamber. Features such as natural ventilation systems, adjustable air outlets, and precise temperature monitoring ensure stable performance. Additionally, built-in timers prevent overheating by automatically stopping tests after pre-set cycles. These features protect both the equipment and the materials under evaluation.

Why is compliance with IEC 60811 important?

IEC 60811 is an international standard for testing electrical insulating and sheathing materials. When a cable aging chamber meets this requirement, it ensures that the test results align with globally recognized benchmarks. This is especially important for manufacturers exporting products, as it demonstrates commitment to international quality standards and facilitates smoother entry into foreign markets.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

BalitaAug.23,2025

-

Advancing Precision with Profile Projector Technology

BalitaAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

BalitaAug.23,2025

-

Ensuring Safety and Compliance

BalitaAug.23,2025

-

Electrical Properties Testing in Modern Applications

BalitaAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

BalitaAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy