Universal Resistance Testing Setup for Accurate Material Evaluation and Performance Analysis

Universal Resistance Fixture A Cornerstone in Material Testing

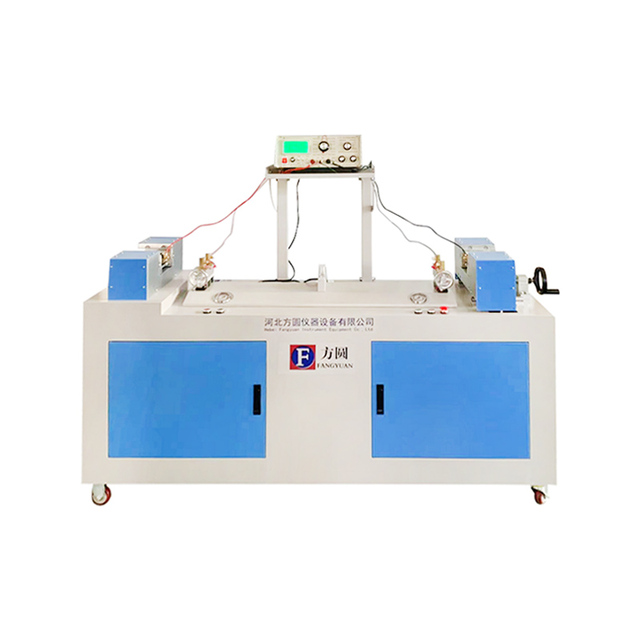

In the ever-evolving world of material science and engineering, the quest for understanding and improving material properties is ceaseless. One of the tools that play a critical role in this domain is the Universal Resistance Fixture (URF). Designed to evaluate a material's resistance mechanisms, this fixture is invaluable for researchers and engineers who aim to enhance the performance and longevity of materials across a variety of applications.

Understanding Universal Resistance Fixtures

A Universal Resistance Fixture is a sophisticated device used in laboratories and testing facilities to measure a material’s resistance to various forms of mechanical, thermal, and environmental stress. It facilitates controlled testing conditions that mimic real-world scenarios, enabling researchers to gather accurate data without the unpredictability of field tests.

Typically constructed from robust materials that can withstand extreme conditions, the URF incorporates several components, including load cells, strain gauges, and electronic control systems. These elements work synergistically to apply precise loads and measurement technologies to assess the performance of a material under different circumstances.

Applications of Universal Resistance Fixtures

The URF is widely used in diverse sectors such as aerospace, automotive, construction, and electronics. In aerospace engineering, for instance, materials must endure high stress and temperature variations. By using a URF, engineers can test materials like aluminum alloys or composites to determine their limits and identify potential failure points. This ability to simulate various conditions makes it easier to predict how materials will behave in actual use.

In the automotive industry, the URF is essential for evaluating materials used in everything from engine components to body structures. The fixture allows for comprehensive analysis regarding fatigue, impact resistance, and tensile strength, which in turn influences design decisions for safety and efficiency.

The Importance of Accurate Testing

universal resistance fixture

Accurate testing is paramount in material science. The data collected from URF experiments help researchers understand the underlying mechanisms of material failure, such as fracture propagation or corrosion. By pinpointing these failure modes, laboratories can develop materials with enhanced properties, thus contributing to advancements in safety and reliability.

For instance, in the development of concrete for construction projects, a URF can be used to measure compressive strength and resistance to shear. This information ensures that structures can withstand the rigors of everyday use and environmental stressors, including earthquakes or heavy winds.

Furthermore, compliance with international standards is increasingly important for manufacturers. Using a Universal Resistance Fixture enables businesses to demonstrate that their materials and products meet stringent benchmarks, ensuring both regulatory compliance and competitive advantage.

Innovations and Future Directions

As technology progresses, so do the capabilities of Universal Resistance Fixtures. Recent innovations include digital interfaces that allow for real-time data monitoring and automated systems that enhance repeatability and consistency in testing. Integration with artificial intelligence also opens new avenues for accelerated material development, enabling rapid analysis and optimization.

Moreover, the push towards sustainability is reshaping the materials industry. The URF will play an essential role in testing eco-friendly materials and composites that contribute to a circular economy, ensuring that new products are not only effective but also sustainable.

Conclusion

The Universal Resistance Fixture stands as a pillar in the field of material testing, equipping engineers and researchers with the tools necessary to finesse and fortify materials for diverse applications. Its ability to simulate real-world conditions, coupled with accurate and reliable data generation, makes it an indispensable asset in the journey toward innovative material solutions. As advancements continue to unfold, the URF will undoubtedly adapt and evolve, ensuring that the materials of tomorrow are safer, stronger, and more sustainable.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy