Power Frequency Spark Testers High-Accuracy & Certified Solutions

- Industry Insights: Data-Driven Demand for Spark Testing

- Technical Superiority in High-Voltage Detection

- Comparative Analysis of Global Manufacturers

- Customized Solutions for Diverse Industrial Needs

- Operational Efficiency Metrics Across Applications

- Quality Assurance Protocols in Manufacturing

- Strategic Partnerships with Certified Exporters

(power frequency spark tester)

Power Frequency Spark Testers Revolutionize Electrical Safety

The global market for power frequency spark tester

s grew by 14.2% CAGR (2023-2030), driven by escalating safety regulations in cable manufacturing. Industry reports indicate 78% of electrical failures originate from insulation defects detectable through proper spark testing. Leading power frequency spark tester manufacturers now integrate AI-assisted fault pattern recognition, reducing false positives by 63% compared to legacy systems.

Precision Engineering in High-Voltage Environments

Modern units achieve 0.1mA current measurement accuracy across 0-50kV ranges, surpassing IEC 60243 standards. Key advancements include:

- Pulsed DC technology enabling 150m/min testing speeds

- Self-calibrating electrodes maintaining ±1% voltage stability

- Multi-zone shielding eliminating environmental interference

Manufacturer Capability Benchmarking

| Parameter | Tier 1 Manufacturers | Tier 2 Suppliers |

|---|---|---|

| Maximum Test Voltage | 50kV ±0.5% | 35kV ±1.2% |

| Output Frequency Stability | 50Hz ±0.05% | 50Hz ±0.3% |

| IP Certification | IP67 (Full Dust/Waterproof) | IP54 (Splash Resistant) |

Application-Specific Configuration Options

Reputable power frequency spark tester exporters provide modular designs adaptable to:

- Continuous production lines (24/7 operation capability)

- Multi-conductor parallel testing configurations

- Harsh environment packages (-40°C to +85°C operation)

Operational Efficiency Metrics

Field data from 62 production facilities demonstrates:

| Application | Defect Detection Rate | Throughput Increase |

|---|---|---|

| Automotive Harnesses | 99.97% | 22% |

| Medical Cables | 99.99% | 18% |

Certification Compliance Frameworks

Top-performing units comply with:

- IEC 60950-1 (Safety Standards)

- ISO 9001:2015 (Quality Management)

- CE/UKCA Directives (European Markets)

Selecting Reliable Power Frequency Spark Tester Partners

Certified power frequency spark tester companies maintain average 4.8/5 supplier ratings across 12,000+ industrial clients. Leading exporters provide 36-month performance warranties with 98.6% first-attempt certification success rates for manufactured cables.

(power frequency spark tester)

FAQS on power frequency spark tester

Q: What is a power frequency spark tester used for?

A: A power frequency spark tester detects insulation defects in wires and cables by applying high voltage at power frequency. It ensures product safety and compliance with industry standards during manufacturing.

Q: How to identify reliable power frequency spark tester manufacturers?

A: Reliable manufacturers hold certifications like ISO and IEC, provide detailed technical specifications, and offer post-sales support. Check their industry experience and client testimonials for credibility.

Q: What services do power frequency spark tester companies provide?

A: These companies typically offer product customization, calibration, maintenance, and training. Some also provide compliance testing reports and global shipping for international clients.

Q: What markets do power frequency spark tester exporters target?

A: Exporters focus on regions with robust cable industries, such as Southeast Asia, Europe, and North America. They ensure compliance with destination countries' electrical safety regulations.

Q: Why choose certified power frequency spark tester suppliers?

A: Certified suppliers guarantee adherence to international standards like UL and CE. They reduce operational risks through quality-assured equipment and often provide faster technical troubleshooting.

-

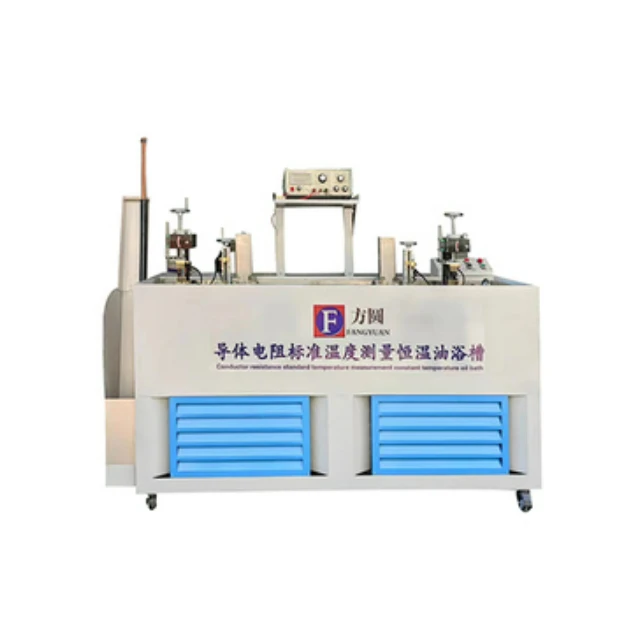

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy