Ots . 03, 2025 00:46

Back to list

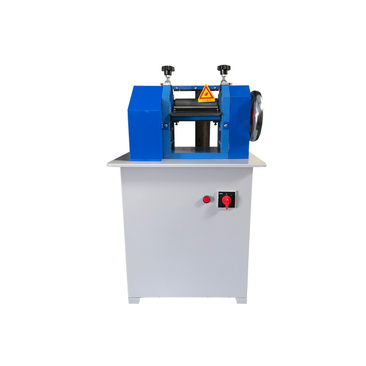

custom electronic universal tensile testing machine

Investing in a custom electronic universal tensile testing machine offers unparalleled advantages for manufacturers and researchers alike. The realm of materials testing necessitates precision, flexibility, and reliability—qualities that are indispensable for advancing product development and ensuring quality assurance. Tailored tensile testing solutions meet the nuanced needs of diverse industries ranging from aerospace to biomedical engineering.

In terms of authoritativeness, having a custom solution sets a company apart as a leader in innovation and quality assurance. Organizations utilizing such equipment often find themselves at the forefront of technical proficiency, enhancing their reputation both within their industry and among their clientele. The precision and customization afforded by these machines ensure that manufacturers can validate their materials to exact specifications, a critical factor for gaining certifications that bolster credibility in competitive markets. Trustworthiness is cultivated through the consistent performance and verified results that a custom tensile testing machine provides. By facilitating comprehensive data collection and analysis, these machines bolster confidence in a manufacturer’s quality assessment processes. Clients can rest assured that every batch of material tested undergoes rigorous scrutiny, backed by a machine configured to extract the highest standard of data fidelity. The peace of mind offered by these machines extends beyond just the immediate tests conducted—it permeates the entire supply chain, reinforcing trust in the final products delivered to consumers and end-users. For any organization looking to optimize their testing capabilities, investing in a custom electronic universal tensile testing machine is not merely a choice—it is a strategic enhancement to their operational framework. The nuances of material testing are such that capturing the full breadth of mechanical behavior requires tools that are as adaptable and innovative as the industries they serve. Custom solutions embody this ethos, driving forward the imperative of excellence with each test conducted. As the forefront of material testing continues to evolve, so too should the tools we employ, ensuring that quality and precision remain uncompromised.

In terms of authoritativeness, having a custom solution sets a company apart as a leader in innovation and quality assurance. Organizations utilizing such equipment often find themselves at the forefront of technical proficiency, enhancing their reputation both within their industry and among their clientele. The precision and customization afforded by these machines ensure that manufacturers can validate their materials to exact specifications, a critical factor for gaining certifications that bolster credibility in competitive markets. Trustworthiness is cultivated through the consistent performance and verified results that a custom tensile testing machine provides. By facilitating comprehensive data collection and analysis, these machines bolster confidence in a manufacturer’s quality assessment processes. Clients can rest assured that every batch of material tested undergoes rigorous scrutiny, backed by a machine configured to extract the highest standard of data fidelity. The peace of mind offered by these machines extends beyond just the immediate tests conducted—it permeates the entire supply chain, reinforcing trust in the final products delivered to consumers and end-users. For any organization looking to optimize their testing capabilities, investing in a custom electronic universal tensile testing machine is not merely a choice—it is a strategic enhancement to their operational framework. The nuances of material testing are such that capturing the full breadth of mechanical behavior requires tools that are as adaptable and innovative as the industries they serve. Custom solutions embody this ethos, driving forward the imperative of excellence with each test conducted. As the forefront of material testing continues to evolve, so too should the tools we employ, ensuring that quality and precision remain uncompromised.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy