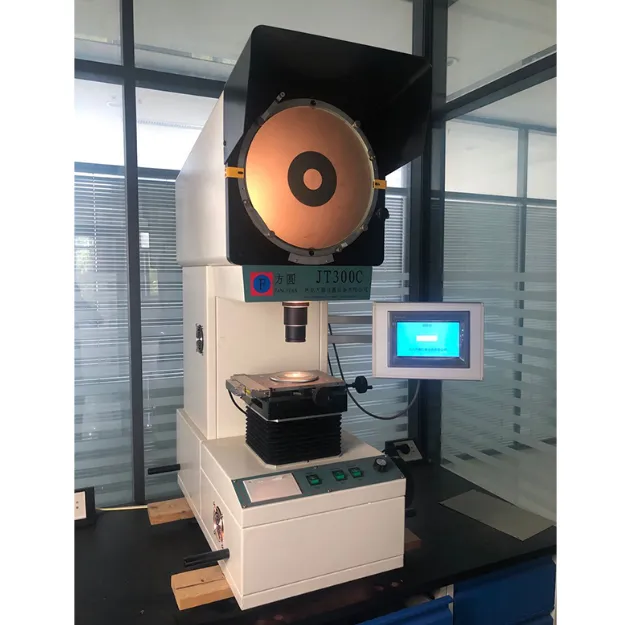

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

In an era defined by smart production lines and intelligent quality control, the Digital Measurement Projector has emerged as a revolutionary solution for dimensional inspection. Designed to integrate high-resolution optics with intelligent software, this advanced optical measuring instrument eliminates the guesswork from manual measurement. Whether in aerospace, electronics, or precision machining, the Digital Measurement Projector delivers fast, reliable, and contact-free analysis for a new generation of manufacturers.

The Working Principle Behind the Digital Measurement Projector

The core of the Digital Measurement Projector lies in its ability to magnify and digitally display a specimen's silhouette or edge on a high-definition screen for precise dimensional analysis. Utilizing LED or halogen light sources, the system projects an enlarged shadow of the object onto a built-in digital imaging sensor. This projection is then processed through a high-accuracy lens system and interpreted using advanced image analysis software.

Unlike traditional mechanical gauges or microscopes, the Digital Measurement Projector enables instant and repeatable measurements of length, radius, angle, and geometric tolerance without physical contact. The integration of real-time software analysis ensures micron-level precision while reducing human error. Operators can zoom in or rotate the view, apply overlays, and document every detail with automatic report generation—enhancing traceability and accountability.

Comparing Digital Measurement Projector to Traditional Measurement Projectors

While traditional Measurement Projector systems still hold value in some facilities, the difference in usability and performance is substantial. Conventional optical projectors rely heavily on manual interpretation and measurement using screen overlays or reticles. This method is time-consuming and prone to variation depending on the operator’s skill and lighting conditions.

In contrast, the Digital Measurement Projector automates nearly every step. Equipped with digital zoom, autofocus, automatic edge detection, and touch-screen control, it requires minimal training to operate. Measurements are displayed numerically on-screen, and inspection reports can be exported directly via USB or network. Unlike older systems that require dark rooms or large screen sizes, this Smart Projector functions under standard lighting and offers compact, desktop-friendly footprints.

The introduction of digital calibration standards has also dramatically increased the accuracy and reliability of the optical measuring instrument, making it the preferred choice for companies looking to upgrade their quality control departments.

Industry Applications of the Digital Measurement Projector

Thanks to its versatility and non-contact design, the Digital Measurement Projector is widely used across several demanding industries. In precision metalworking, it inspects complex parts like gear teeth, fasteners, or stamped components with unparalleled accuracy. In the electronics sector, it plays a critical role in checking PCB layouts, IC packages, and micro-connectors where small misalignments can cause catastrophic failure.

Medical device manufacturers use the Smart Projector to verify the contours and dimensions of surgical instruments and implants. The aerospace industry relies on the optical measuring instrument for high-reliability components like turbine blades and engine housings. Even in plastic injection molding, the system ensures mold consistency and part repeatability from batch to batch.

Its speed and precision have also made the Digital Measurement Projector popular in educational labs and R&D departments, where prototyping and testing require fast measurement feedback without damaging samples.

Advantages That Make the Digital Measurement Projector Stand Out

What makes the Digital Measurement Projector a must-have for modern inspection labs isn’t just its digital capabilities—it’s the fusion of automation, consistency, and ease of use. Unlike contact-based measuring tools that may distort soft or thin materials, the non-contact method used by this optical measuring instrument preserves the integrity of even the most delicate components.

این Measurement Projector can perform batch inspections with programmable macros, allowing teams to inspect dozens of parts using the same criteria in seconds. Digital overlays and CAD import functionality further reduce setup time. The Smart Projector also eliminates the need for separate lighting setups or complicated fixture design, saving valuable floor space and maintenance costs.

In addition, real-time comparison against preloaded part profiles enhances quality control, alerting operators immediately to defects. This feature is especially valuable in industries requiring zero-defect policies, such as automotive electronics and aerospace engineering.

Digital Measurement Projector FAQs

What is the working principle of the Digital Measurement Projector?

It uses high-resolution optics to project the enlarged silhouette of an object onto a digital sensor, then analyzes the shape using software algorithms to measure dimensions with high accuracy and no physical contact.

How does the Digital Measurement Projector differ from traditional Measurement Projector systems?

این Digital Measurement Projector automates measurements with digital zoom, edge detection, and real-time analysis, while traditional systems rely on manual overlays and are more prone to user error and slower inspection times.

In which industries is the Digital Measurement Projector most commonly used?

It’s widely used in aerospace, electronics, automotive, medical devices, precision machining, and educational research due to its high precision, speed, and ability to inspect small or complex parts.

What are the main benefits of using a Smart Projector in a production environment?

این Smart Projector reduces inspection time, improves measurement consistency, allows for digital documentation, and supports non-contact inspection, all of which streamline the quality control process and increase productivity.

Can the optical measuring instrument be integrated into automated production lines?

Yes, many models of the optical measuring instrument support integration with barcode scanners, robotic arms, and factory management systems to allow for seamless operation in automated environments.

-

The Role of Tensile Force Testers in Quality Control and Material Science

اخبارAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

اخبارAug.01,2025

-

Density Balance in Forensic Science

اخبارAug.01,2025

-

Advanced Optical Measurement Technologies

اخبارAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

اخبارAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

اخبارJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy