Innovative Solutions for Electronic Tensile Strength Testing Equipment and Technology Advancement

The Importance of Electronic Tensile Strength Testing Equipment in Material Science

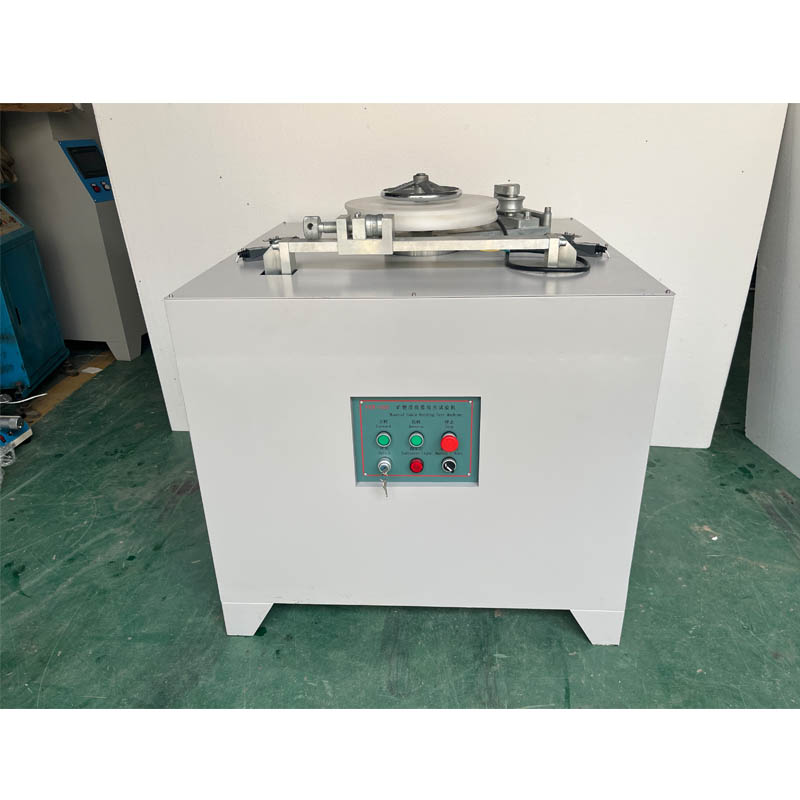

In today's fast-paced industrial and manufacturing landscape, the need for rigorous quality control and material testing has never been more critical. One of the cornerstones of materials testing is the evaluation of tensile strength, which measures how much force a material can withstand while being stretched or pulled before failing. Electronic tensile strength testing equipment has emerged as a pivotal tool for engineers and material scientists in understanding the properties of various materials.

Tensile strength testing aims to determine the ability of a material to withstand tension; it is crucial for everything from metals to polymers. The advancement of electronic tensile testing equipment has revolutionized how these tests are conducted, providing accurate and repeatable results. Unlike traditional mechanical testing systems, electronic equipment utilizes advanced sensors and digital interfaces to collect data, analyze results, and even control testing parameters in real-time.

One of the primary advantages of electronic tensile strength testing equipment is its accuracy. The incorporation of digital technology allows for precise measurements of force, elongation, and other important parameters. Traditional methods might be prone to human error or environmental influences, but modern electronic systems provide consistently reliable results. This precision is essential for researchers and manufacturers who need to meet stringent industry standards and regulatory requirements.

Furthermore, digital systems often come equipped with software that enables comprehensive data analysis. Users can visualize stress-strain curves and identify critical points such as yield strength, ultimate tensile strength, and elongation at break. These insights are invaluable for material selection and design optimization, particularly in industries like aerospace, automotive, and construction, where performance and safety are paramount.

electronic tensile strength testing equipment company

In terms of user interface, electronic tensile strength testing equipment has also made significant strides. Many modern systems feature intuitive touch screens and user-friendly software that simplify the testing process. Operators can easily set up tests, adjust parameters, and monitor the process without needing extensive training or technical expertise. This accessibility has made it possible for a broader range of professionals to employ tensile testing in their work, thus enhancing overall quality assurance.

The versatility of electronic tensile testing equipment is another notable benefit. These machines can accommodate a wide range of materials, including metals, plastics, rubber, and composite materials. This adaptability is crucial as industries increasingly work with advanced materials that require different testing approaches. Additionally, some electronic systems can perform various tests, such as compression and flexural testing, further streamlining the testing process within a laboratory or manufacturing setting.

As industries continue to demand higher performance and compliance with global standards, the role of electronic tensile strength testing equipment becomes increasingly significant. Companies that invest in state-of-the-art testing equipment not only ensure the quality and reliability of their products but also strengthen their competitive edge in the market. This investment translates into reduced material failures, increased customer satisfaction, and ultimately, greater profitability.

In conclusion, electronic tensile strength testing equipment is an indispensable asset in the field of material science. Its accuracy, user-friendly nature, and versatility provide a solid foundation for understanding the mechanical properties of materials. As technology continues to advance, these systems will undoubtedly evolve further, providing even more robust solutions to meet the ever-growing demands of modern industries. Whether for research, quality control, or product development, the importance of electronic tensile strength testing cannot be overstated in the pursuit of engineering excellence and innovation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy