DQ-F Superfine Wire Conductor Resistance Fixture: Precision Testing

Table of Contents

- Industry Trends in Superfine Conductor Testing

- Manufacturing Process Flow of the DQ-F Fixture

- Technical Specifications

- Critical Application Scenarios

- Key Technical Advantages

- Vendor Comparison: DQ-F vs. Standard Fixtures

- Tailored and Customized Solutions

- Real-World Application Case Studies

- Frequently Asked Questions (FAQ)

- Lead Time & Fulfillment

- Warranty & Customer Support

- Authoritative References

Introduction to Precision Conductor Resistance Testing

In an era defined by miniaturization and high-performance electronics, the integrity of superfine wire conductors is paramount. Accurate measurement of their electrical resistance is a critical quality control parameter, directly impacting product reliability and operational efficiency. The DQ-F Superfine Wire Conductor Resistance Fixture is engineered precisely for this demanding application, offering unparalleled precision and repeatability in testing these delicate materials. This comprehensive article delves into the technical intricacies, application benefits, and strategic advantages of deploying such advanced testing equipment in various industrial contexts.

Industry Trends in Superfine Conductor Testing

The global market for fine and superfine wires is experiencing robust growth, driven by rapid advancements in sectors such as consumer electronics, medical devices, automotive electrification, and aerospace. These industries increasingly demand conductors with smaller diameters, higher conductivity, and superior mechanical properties. Consequently, the need for highly accurate and reliable resistance testing solutions is more pronounced than ever. Traditional testing methods often fall short in handling the delicate nature and minute dimensions of these conductors, leading to inconsistent results and potential damage to samples.

Key trends influencing the demand for specialized fixtures like the DQ-F Superfine Wire Conductor Resistance Fixture include:

- Miniaturization: Devices are shrinking, requiring finer wires (e.g., down to 10 microns) in components like micro-coils, sensors, and flexible circuits.

- Increased Data Transmission Rates: High-frequency applications necessitate low resistance and impedance for signal integrity, making precise resistance measurement crucial.

- Electrification of Vehicles: Automotive wiring harnesses and battery management systems demand durable, high-performance fine wires, where resistance variation directly impacts efficiency and safety.

- Medical Device Innovation: Implants and surgical tools use ultra-fine wires, requiring meticulous quality control to ensure patient safety and device functionality.

- Automation and Data Integration: Manufacturers seek testing solutions that can be easily integrated into automated production lines and provide digital data for statistical process control (SPC).

These trends collectively underscore the critical role of advanced testing fixtures in ensuring the quality, performance, and compliance of superfine wire conductors throughout their lifecycle.

Manufacturing Process Flow of the DQ-F Fixture

The production of the DQ-F Superfine Wire Conductor Resistance Fixture involves a meticulously controlled multi-stage process, ensuring the precision, durability, and reliability required for micro-ohm measurements. Each stage adheres to stringent quality protocols, mirroring the demands of target industries such as aerospace, medical electronics, and precision instrument manufacturing.

1. Material Selection & Procurement

- Materials: High-grade, non-magnetic stainless steels (e.g., SUS304 or SUS316 for structural components) are selected for their corrosion resistance, mechanical stability, and minimal electromagnetic interference. Contact points utilize specific alloys like beryllium copper with gold plating to ensure low contact resistance and minimize thermoelectric EMF effects. Insulation materials (e.g., PEEK, PTFE) are chosen for high dielectric strength and dimensional stability.

- Supplier Qualification: All raw materials are sourced from ISO 9001 certified vendors, with material certificates of conformity (MTCs) validated upon receipt.

2. Precision CNC Machining

- Component Manufacturing: Structural elements, clamping mechanisms, and probe guides are produced using advanced multi-axis CNC machining centers. This ensures tolerances are maintained within microns, crucial for repeatable wire positioning and contact force.

- Surface Finish: Critical surfaces undergo precision grinding and polishing to achieve optimal flatness and minimize wear.

3. Surface Treatment & Plating

- Corrosion Resistance: Stainless steel components may undergo passivation or electropolishing.

- Contact Plating: Beryllium copper probes and contacts are typically gold-plated (e.g., 50-100 micro-inches over nickel barrier) to ensure minimal and stable contact resistance, vital for accurate four-wire (Kelvin) measurements of low resistances. This also prevents oxidation, extending service life in environments ranging from cleanrooms to general laboratory settings.

4. Assembly & Integration

- Cleanroom Assembly: For highly sensitive components, assembly takes place in controlled environments to prevent contamination.

- Precision Alignment: Critical sub-assemblies, particularly the clamping jaws and Kelvin probes, are meticulously aligned using optical comparators or vision systems to ensure precise and uniform contact with the superfine wire conductor.

- Wiring & Connection: Internal wiring utilizes low-thermal EMF copper wire to minimize spurious voltages, enhancing measurement stability. Connectors are specified for high reliability and compatibility with standard resistance meters.

5. Calibration & Testing Standards

- Functional Testing: Each DQ-F Superfine Wire Conductor Resistance Fixture undergoes comprehensive functional testing, including checks for clamping force, wire strain relief, and mechanical repeatability.

- Electrical Performance Verification: Resistance measurement accuracy and stability are verified using calibrated reference resistors and precision micro-ohmmeters. This includes tests for contact resistance, insulation resistance, and thermal drift.

- Adherence to Standards: Testing is conducted in accordance with relevant international standards such as ISO 17025 (for calibration procedures), ASTM B193 (standard test method for resistivity of electrical conductor materials), and IEC 60068 (environmental testing). Our fixtures are built to ensure compliance with these rigorous benchmarks.

6. Quality Assurance & Certification

- Final Inspection: A final visual and dimensional inspection ensures all specifications are met.

- Documentation: Each fixture is delivered with a calibration certificate, user manual, and full traceability of materials and processes.

Service Life: Designed for an extended service life exceeding 10 years under normal operating conditions, the fixture's robust construction and high-quality materials minimize wear and degradation, ensuring consistent performance over time. Regular calibration and maintenance are recommended to uphold peak accuracy. Target industries include petrochemical (for instrumentation wiring), metallurgy (quality control of specialized alloys), water supply & drainage (sensor and control wiring), and particularly electronics, where precision is non-negotiable.

Demonstrated Advantages: In typical application scenarios, the DQ-F Superfine Wire Conductor Resistance Fixture provides superior energy saving by preventing inaccurate readings that could lead to wasteful material reprocessing. Its advanced design also ensures corrosion resistance, especially important when handling diverse conductor materials in varying environmental conditions, contributing to long-term reliability and reduced downtime in test laboratories.

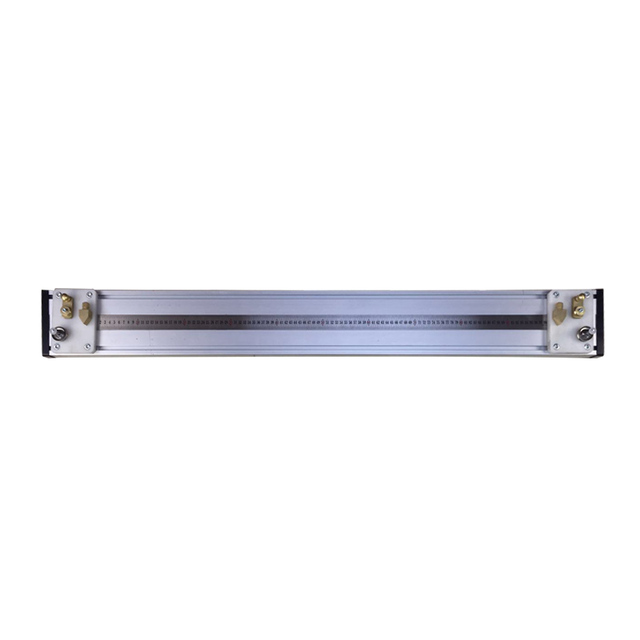

Technical Specifications of the DQ-F Superfine Wire Conductor Resistance Fixture

The performance of the DQ-F Superfine Wire Conductor Resistance Fixture is defined by its precise engineering and advanced features, tailored to meet the exacting requirements of modern material testing. The following table details key parameters:

| Parameter | Specification | Description |

|---|---|---|

| Wire Diameter Range | 0.01 mm to 0.5 mm | Accommodates a broad spectrum of superfine wires, from ultra-fine bonding wires to small-gauge magnet wires. |

| Measurement Principle | Four-wire (Kelvin) connection | Eliminates lead resistance and contact resistance errors for highly accurate low-resistance measurements. |

| Resistance Range | 1 µΩ to 10 kΩ (system dependent) | Fixture supports measurement across a wide range when paired with suitable micro-ohmmeters. |

| Clamping Mechanism | Precision spring-loaded, adjustable force | Ensures consistent and gentle clamping to prevent wire deformation while maintaining excellent electrical contact. |

| Contact Material | Gold-plated Beryllium Copper | Optimized for low contact resistance, high conductivity, and minimal thermoelectric EMF. |

| Operating Temperature Range | 0°C to +50°C | Stable performance in typical laboratory and industrial environments. |

| Dimensions (L x W x H) | ~150 mm x 100 mm x 80 mm | Compact design for ease of integration into existing test setups. |

| Weight | ~0.8 kg | Lightweight yet robust construction. |

| Compatibility | Standard Banana Plug / BNC connectors | Ensures seamless integration with most commercial precision resistance meters. |

Critical Application Scenarios

The versatility and precision of the DQ-F Superfine Wire Conductor Resistance Fixture make it indispensable across a multitude of high-tech and manufacturing industries:

- Electronics Manufacturing: Essential for quality control of bonding wires in semiconductors, coil windings in miniature motors, and fine traces on flexible printed circuit boards (FPCBs). Ensures the reliability of micro-components in smartphones, wearables, and IoT devices.

- Automotive Industry: Used in the production and R&D of wiring harnesses for electric vehicles (EVs), advanced driver-assistance systems (ADAS), and engine management units. Precise resistance measurement guarantees optimal power delivery and signal integrity in critical automotive electronics.

- Medical Devices: Crucial for ensuring the integrity of ultra-fine wires in catheters, pacemakers, neural probes, and other sensitive medical instruments where even minor resistance deviations can have life-threatening implications.

- Aerospace & Defense: Testing of specialized lightweight conductors used in avionics, satellite systems, and military equipment. The demand for high reliability in extreme conditions makes accurate resistance testing a non-negotiable requirement.

- Material Science & R&D: Laboratories developing new conductive alloys, superconducting materials, or innovative wire insulation technologies rely on precise resistance measurements to characterize material properties and validate experimental results.

- Cable & Wire Manufacturers: For internal quality assurance and compliance testing of their superfine wire product lines, ensuring each batch meets specified electrical performance criteria before market release.

In these scenarios, the ability of the DQ-F Superfine Wire Conductor Resistance Fixture to provide consistent, repeatable measurements of exceptionally delicate wires without damage is a significant operational advantage, reducing material waste and improving overall product quality.

Key Technical Advantages

The DQ-F Superfine Wire Conductor Resistance Fixture distinguishes itself through several critical technical advantages that address the unique challenges of superfine wire testing:

- Unparalleled Measurement Precision: Utilizes a true four-wire Kelvin connection, which independently drives current and senses voltage. This methodology effectively nullifies errors introduced by lead resistance and contact resistance, providing highly accurate readings, especially critical for low-resistance superfine wires.

- Damage-Free Clamping Mechanism: Engineered with a specialized spring-loaded, adjustable-force clamping system. This design applies consistent, gentle pressure across the wire, preventing deformation, nicks, or breaks that are common with less sophisticated fixtures. This is crucial for delicate wires with diameters as small as 0.01 mm.

- Reduced Thermoelectric EMF: Constructed with materials and contact points (gold-plated Beryllium Copper) that minimize the generation of thermoelectric electromotive force (EMF) at junctions. This ensures measurement stability and accuracy, particularly important when measuring micro-ohm values.

- High Repeatability & Reproducibility: The precise mechanical design ensures that once a wire is clamped, its position and contact geometry are highly repeatable. This allows for consistent measurements across multiple tests and by different operators, crucial for statistical process control (SPC) and quality assurance.

- Ergonomic & User-Friendly Design: Despite its technical sophistication, the fixture is designed for ease of use, minimizing operator fatigue and accelerating throughput in high-volume testing environments. Quick-release mechanisms and clear alignment guides contribute to efficiency.

- Robust & Durable Construction: Built from high-grade, non-magnetic materials with exceptional mechanical stability and corrosion resistance, ensuring a long operational lifespan even in demanding industrial settings. This reduces the total cost of ownership over time.

- Broad Compatibility: Equipped with standard electrical connectors (e.g., banana plugs), ensuring seamless integration with a wide range of precision micro-ohmmeters and resistance measurement instruments from various manufacturers.

These advantages collectively position the DQ-F Superfine Wire Conductor Resistance Fixture as a superior choice for any application where the accurate and reliable testing of superfine wire conductors is paramount.

Vendor Comparison: DQ-F vs. Standard Fixtures

When selecting a fixture for superfine wire resistance testing, it is crucial to understand the differentiating factors between specialized equipment like the DQ-F Superfine Wire Conductor Resistance Fixture and more generic, standard-issue test fixtures. The table below highlights key comparison points:

| Feature/Parameter | DQ-F Superfine Wire Conductor Resistance Fixture | Generic Standard Fixture |

|---|---|---|

| Supported Wire Diameter | 0.01 mm - 0.5 mm | Typically >0.5 mm or wider range with compromises |

| Clamping Mechanism | Precision spring-loaded, adjustable force, anti-deformation | Screw-type or simple spring, often causing damage/deformation |

| Contact Type & Material | Gold-plated Beryllium Copper Kelvin contacts (4-wire) | Nickel or brass, often 2-wire, higher contact resistance |

| Measurement Accuracy | Superior, minimizes lead & contact errors (µΩ range) | Lower, significant errors for low resistances (mΩ range) |

| Thermoelectric EMF | Minimized due to specialized materials and design | Often a significant source of error in low resistance tests |

| Repeatability & Reproducibility | High, consistent results across tests and operators | Moderate to low, dependent on operator skill and sample integrity |

| Durability & Service Life | High-grade materials, engineered for long-term use (10+ years) | Moderate, components wear quickly, affecting performance |

| Cost (Initial) | Higher initial investment | Lower initial cost |

| Total Cost of Ownership | Lower (due to reduced errors, less retesting, long life) | Higher (due to material waste, retesting, frequent replacement) |

The comparison clearly indicates that while generic fixtures may offer a lower entry price, the long-term operational efficiency, accuracy, and reliability provided by the DQ-F Superfine Wire Conductor Resistance Fixture yield superior value and minimize risks associated with critical component testing.

Tailored and Customized Solutions

Recognizing that unique testing requirements exist across diverse industries, we offer customized solutions for the DQ-F Superfine Wire Conductor Resistance Fixture. Our engineering team collaborates closely with clients to adapt the fixture's capabilities to specific application needs, ensuring optimal performance and seamless integration into existing workflows.

Customization options can include:

- Extended Wire Diameter Range: While the standard DQ-F accommodates 0.01mm to 0.5mm, specific projects may require even finer wire support or slightly larger diameters, which can be addressed through custom clamping jaw designs.

- Specialized Contact Geometries: For non-standard wire profiles (e.g., ribbon cables, square conductors) or specific material surfaces, alternative contact tips and probe arrangements can be developed to ensure optimal Kelvin contact.

- Enhanced Environmental Adaptability: For testing in extreme temperatures (above 50°C or below 0°C), vacuum, or corrosive atmospheres, the fixture can be modified with specialized materials and sealing, enabling its use in environmental chambers.

- Integration with Automated Systems: For high-volume production lines, the DQ-F fixture can be designed with automated loading/unloading interfaces, digital control signals, and data output compatibility for robotic integration.

- Custom Mounting Solutions: Adaptable base plates or mounting brackets can be fabricated to ensure the fixture fits perfectly into existing test stands, enclosures, or inspection stations.

- Proprietary Connector Interfaces: For seamless connection to specific legacy test equipment or proprietary measurement systems, custom connector panels can be integrated.

Our commitment to providing tailored solutions ensures that the DQ-F Superfine Wire Conductor Resistance Fixture is not just a product, but a precision tool perfectly aligned with your unique operational and R&D challenges. We pride ourselves on decades of experience in high-precision testing solutions, serving leading R&D labs and tier-1 manufacturers globally.

Real-World Application Case Studies

Case Study 1: Automotive Sensor Manufacturer

A leading global manufacturer of automotive sensors required precise resistance testing for extremely fine copper wires (0.05 mm diameter) used in their next-generation ABS and airbag sensors. Their previous testing fixture frequently damaged the delicate wires, leading to a high rejection rate of samples and inconsistent measurement data. This resulted in production bottlenecks and delayed product validation cycles.

"Prior to adopting the DQ-F, we struggled with reliable resistance measurements on our fine wires. The new fixture has not only eliminated sample damage but also drastically improved our measurement repeatability, allowing us to confidently meet ISO 26262 functional safety standards. Our test throughput increased by 30%." - Head of Quality Control, Automotive Tier-1 Supplier.

By implementing the DQ-F Superfine Wire Conductor Resistance Fixture, the manufacturer experienced a 95% reduction in sample damage during testing. The fixture's precision clamping and Kelvin contacts provided highly accurate and repeatable resistance values, reducing measurement uncertainty from ±5% to ±0.5%. This improvement significantly accelerated their R&D and quality control processes, leading to faster time-to-market for new sensor technologies and enhanced product reliability.

Case Study 2: Medical Device Component Supplier

A specialist in medical implant components faced challenges in ensuring the electrical integrity of platinum-iridium alloy wires (0.02 mm diameter) used in neurostimulators. The extreme sensitivity of these wires meant traditional fixtures often introduced micro-fractures, compromising device longevity and patient safety. Existing two-wire measurement setups also yielded inconsistent results due to high contact resistance variability.

The adoption of the DQ-F Superfine Wire Conductor Resistance Fixture provided a transformative solution. Its ultra-gentle clamping mechanism combined with gold-plated Kelvin probes allowed for secure, repeatable contact without any material stress or damage. The resultant four-wire measurements offered a tenfold improvement in measurement stability and accuracy, critical for meeting stringent FDA and ISO 13485 regulatory requirements for medical devices. The improved data quality led to optimized wire drawing processes, reducing material waste by 15% and increasing confidence in product performance over its intended service life.

Frequently Asked Questions (FAQ)

-

Q: What is the smallest wire diameter the DQ-F fixture can reliably test?

A: The DQ-F Superfine Wire Conductor Resistance Fixture is designed to reliably test wires down to 0.01 mm (10 microns) in diameter, thanks to its specialized precision clamping mechanism and low-force contacts.

-

Q: Is the DQ-F compatible with all types of resistance meters?

A: Yes, the fixture uses standard electrical connectors (e.g., banana plugs) for its four-wire Kelvin connections, making it compatible with most commercial precision micro-ohmmeters and resistance bridges on the market.

-

Q: How does the DQ-F prevent damage to delicate superfine wires?

A: It employs a unique spring-loaded, adjustable-force clamping system with precision-machined, smooth contact surfaces. This design ensures gentle, consistent pressure across the wire, preventing deformation or breakage, which is a common issue with coarser fixtures.

-

Q: What maintenance is required for the fixture?

A: Routine cleaning of the contact surfaces with appropriate non-abrasive cleaners is recommended. Periodic visual inspection for wear and re-calibration every 12-24 months, depending on usage frequency and internal quality policies, ensures optimal performance and extends the service life of your DQ-F Superfine Wire Conductor Resistance Fixture.

Lead Time & Fulfillment

Standard configurations of the DQ-F Superfine Wire Conductor Resistance Fixture typically have a lead time of 2-4 weeks from order confirmation, subject to current stock levels and production schedules. For customized solutions, lead times will be provided upon detailed specification review, generally ranging from 6-10 weeks to account for design, material procurement, manufacturing, and specialized testing. We maintain transparent communication throughout the order fulfillment process, providing regular updates on production status and shipping timelines.

Warranty & Customer Support

Each DQ-F Superfine Wire Conductor Resistance Fixture is backed by a comprehensive 12-month limited warranty, covering defects in materials and workmanship from the date of purchase. Our commitment extends beyond the sale with a robust customer support infrastructure:

- Technical Support: Access to experienced technical engineers via phone and email for troubleshooting, application guidance, and operational assistance.

- Calibration Services: We offer professional calibration services traceable to national and international standards (e.g., NIST, UKAS) to ensure your fixture maintains its measurement accuracy over its lifespan.

- Spare Parts & Repairs: A readily available inventory of spare parts and efficient repair services minimize downtime, ensuring your testing operations remain uninterrupted.

- Training: On-site or remote training sessions can be arranged to ensure your team maximizes the utility and precision of the DQ-F fixture.

We are dedicated to providing the highest level of service and support to our B2B partners, reinforcing the reliability and long-term value of your investment in the DQ-F Superfine Wire Conductor Resistance Fixture.

Authoritative References

- International Organization for Standardization. ISO/IEC 17025:2017 – General requirements for the competence of testing and calibration laboratories.

- ASTM International. ASTM B193 – Standard Test Method for Resistivity of Electrical Conductor Materials.

- National Institute of Standards and Technology (NIST). Precision Measurement of Low Resistance.

- Institute of Electrical and Electronics Engineers (IEEE). Standards for Electrical Measurements in Low-Resistance Applications.

- European Committee for Electrotechnical Standardization (CENELEC). EN 60068 – Environmental testing for electrical and electronic products.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy