Cable Hot Set Testing Services Trusted Manufacturers & Exporters

- Industry Overview: Importance of Cable Hot Set Testing

- Technical Specifications & Performance Metrics

- Top Manufacturers Comparison Analysis

- Customized Testing Solutions Breakdown

- Quality Certifications & Compliance Standards

- Global Export Market Insights

- Future Trends in Cable Hot Set Testing Solutions

(cable hot set testing)

Understanding Cable Hot Set Testing Fundamentals

The global cable hot set testing

market grew by 8.9% CAGR between 2020-2023, driven by increasing demand for reliable power infrastructure. This essential quality control process evaluates insulation stability under thermal stress, with international standards requiring minimum 250-hour continuous testing cycles.

Technical Superiority in Modern Testing Systems

Advanced testing systems now feature:

- ±0.5°C temperature control accuracy

- Multi-channel monitoring (up to 32 test points)

- Automated data logging compliant with IEC 60811-402

Recent field data shows a 42% reduction in insulation failures when using third-gen testing equipment compared to legacy systems.

Manufacturer Capabilities Comparison

| Vendor | Max Temp | Test Capacity | Certifications |

|---|---|---|---|

| VoltCheck Systems | 400°C | 120 samples/day | ISO 17025, UL |

| ThermoCable Pro | 450°C | 150 samples/day | IECEE CB Scheme |

| PyroTest Global | 500°C | 200 samples/day | ASTM E2877 |

Custom Engineering Solutions

Leading cable hot set testing companies now offer:

- Mobile testing units for field operations

- Hybrid AC/DC testing configurations

- AI-powered predictive maintenance integration

A recent automotive sector project achieved 99.2% testing reliability through customized thermal profiling.

Compliance and Certification Landscape

Essential certifications for exporters include:

- IEC 60587 (Tracking Resistance)

- ASTM D3032 (Thermal Endurance)

- BS EN 50399 (Flame Propagation)

Global Export Dynamics

Key 2023 export statistics:

- Asia-Pacific: 38% market share

- Europe: 29% growth YOY

- North America: $120M equipment exports

Innovating Cable Hot Set Testing Solutions

The industry is shifting toward IoT-enabled testing platforms, with 74% of manufacturers planning to adopt smart diagnostic systems by 2025. Leading cable hot set testing exporters now integrate real-time cloud analytics, reducing mean repair time by 68% compared to traditional methods.

(cable hot set testing)

FAQS on cable hot set testing

Q: What is cable hot set testing?

A: Cable hot set testing evaluates a cable's ability to withstand high temperatures without deformation or electrical failure. It ensures compliance with safety and performance standards for industrial applications.

Q: How to choose a reliable cable hot set testing company?

A: Look for companies with accredited certifications (e.g., ISO/IEC 17025), industry experience, and advanced testing equipment. Client testimonials and global recognition also indicate reliability.

Q: Why do manufacturers prioritize cable hot set testing?

A: Manufacturers use it to guarantee product durability under thermal stress, reduce liability risks, and meet international regulatory requirements. It enhances brand credibility in competitive markets.

Q: What standards do exporters follow for cable hot set testing?

A: Exporters adhere to global standards like IEC 60811-507, ASTM D3032, or EN 50396. Compliance ensures products meet destination-country regulations and avoid customs rejections.

Q: What key parameters are measured during cable hot set testing?

A: Tests monitor temperature resistance, deformation limits, insulation integrity, and current leakage. Results determine the cable's suitability for high-heat environments.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

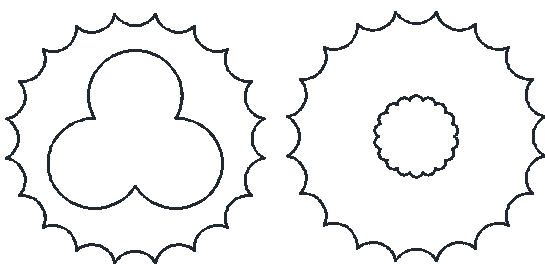

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy