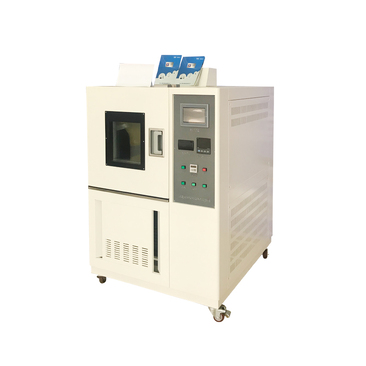

FDW-LJC Low Temperature Automatic Intelligent Test Machine (Winding,Stretching,Impact)

Product Description

The machine meets UL standard and GB/T2951 standard of low temperature drawing, low temperature winding, low temperature impact test standard. The test machine is the latest development of a low temperature tensile, winding automatic intelligent as one type of testing machine, the device uses a man-machine interface control, intelligence and convenient operation easier, and with a micro-printer toprint test data. This machine includes four devices: high and low temperature test chamber, electric low temperature tensile test device, low temperature winding test device, low temperature impact test device.The high and low temperature test chamber simulates the high and low temperature environment and is widely used to determine the adaptability of electrical and electronic products to high and low temperature environments (especially the changes in the electrical and mechanical properties of the product).Meet the technical conditions of GB10592-89 high and low temperature test chamber, GB11158-89 high temperature test chamber technical conditions, GB10589-89 low temperature test chamber technical conditions, GB2423.1 low temperature test-test A, GB2423.2 high temperature test-test B, IEC68-2 -1 Test A, IEC68-2-2 Test B.

1. Electric low temperature tensile test device is suitable for low temperature tensile test of wire and cable insulation and sheath materials. This product is all made of stainless steel, exquisite appearance, safe and reliable; easy to read, stable and high precision; no manual calculation, easy to operate.

2. The electric low temperature winding test device meets the standards of GB2951.14-2008,GB/T2951.4-1997, JB/T4278.11-2011, GB2099-2008,VDE0472 and IEC884-1. It is suitable for testing the performance of round cable or round insulated core at low temperature.

3. Manual low-temperature impact test device is used to measure the insulation of wires and cables, outer sheaths, plugs and sockets, building insulation electrical bushings, and accessories. After the specified cooling time, the hammer drop from a height, so that the sample returns to near room temperature, use normal eyesight to judge whether the sample is cracked. This device complies with standards such as GB2951.14-2008 and GB1.4T 2951.4-1997.

Technical Parameter

1. Low temperature test chamber

a.Studio size(mm): 500(L) x 600(W) x500(H) (other sizes are customized)

b.Temperature range: -40 ~ 150℃

c.Temperature fluctuation: ±0.5℃ (without load)

d.Temperature uniformity: ± 2℃

e.Heating and cooling average rate: 0.7℃ ~ 1.0℃/min ( no load )

f.Time setting: 0 ~ 9999H / M / S

2. Electric low temperature tensile device

a.Motor 90W, installed in the electric control box of the low temperature chamber

b.Maximum tensile strength: 220mm

c.Tensile speed: 20 ~ 30mm/min

d.Chuck type: non-self-tightening type

e.Sample specifications:Ⅰ,Ⅱ dumbbell piece

f.Data display: direct reading elongation

3. Electric low temperature winding test device

a.Winding sample diameter: Ф2.5 ~ Ф12.5 mm

b.Winding rod diameter: Ф4.0 ~ Ф50mm, 12 rods in total

c.Thread guide jacket: Ф1.2 ~ Ф14.5mm, 10 types in total

d.Number of sample winding turns: 2-10 circles

e.Winding speed: 5s/circle

4. Manual low-temperature impact test device

a.Impact height: 100mm

b.Weight: 100g, 200g, 300g, 400g, 500g, 600g, 750g, 1000g, 1250g, 1500g

c.This series of devices are all made of stainless steel

d.Number of samples: three

5. Rated voltage of the whole machine: AC220V / 50Hz, 20A.