Uea FYCS-Z a me nā mea ho'āʻo ho'āʻo i hoʻopaʻa ʻia i ke kaula (Mass Flow Controller)

Hōʻike huahana

He kūpono ia no ka loiloi ʻana i ka hiki ke hoʻonohonoho kū pololei o ka uea i hoʻopaʻa ʻia a me ke kaula a i ʻole ke kaula optical e hoʻopaʻa i ka pālahalaha ʻana o ka lapalapa ma lalo o nā kūlana i kuhikuhi ʻia.

Kūlana

E hoʻokō me GB18380.31-2022 "Ka hoʻāʻo ʻana o nā kaula ma lalo o ke ahi ahi Mahele 3: Ke hoʻokomo pono ʻana o ka uea i hoʻopaʻa ʻia a me ke kaula hoʻāʻo hoʻāʻo hoʻolaha ʻana i ke ahi", e like me IEC60332-3-10:2000.

Ma ka manawa like e hoʻokō i nā koi o ka papa 4 o GB / T19666-2019 "General Principles of Flame Retardant and Refractory Wire and Cable" maʻamau.

GB/T18380.32--2022/IEC60332--3--21: 2015 "Ka ho'āʻo ʻana o nā uwila uila a me nā kaula optical ma lalo o nā kūlana lapalapa Mahele 32: Ua hoʻonohonoho pono ʻia ka uea a me ke kaula uila i hoʻāʻo ʻia ʻo AF / R ʻano ʻano".

GB/T18380.33--2022/IEC60332--3--22: 2015 "Ka hoʻāʻo ʻana o nā uwila uila a me nā kaula optical ma lalo o nā kūlana lapalapa Mahele 33: Ua hoʻokomo ʻia i ka uea i hoʻopaʻa ʻia a me ke kaula uila a me ka hoʻāʻo ʻana i ka ʻāpana A".

GB/T18380.35--2022/IEC60332--3--24:2015 "Ka ho'āʻo ʻana o nā uwila uila a me nā kaula optical ma lalo o nā kūlana lapalapa ʻĀpana 35: Ua hoʻokomo ʻia i ka uea a me ka lapalapa ahi i hoʻāʻo ʻia i ka māhele C",

GB/T18380.36--2022/IEC60332--3--25: 2015 "Ka hoʻāʻo ʻana o nā uwila uila a me nā kaula optical ma lalo o nā kūlana ahi Mahele 36: ʻO ka uea i hoʻopaʻa ʻia i hoʻopaʻa ʻia a me ke kaula uila hoʻolaha ākea ākea D.

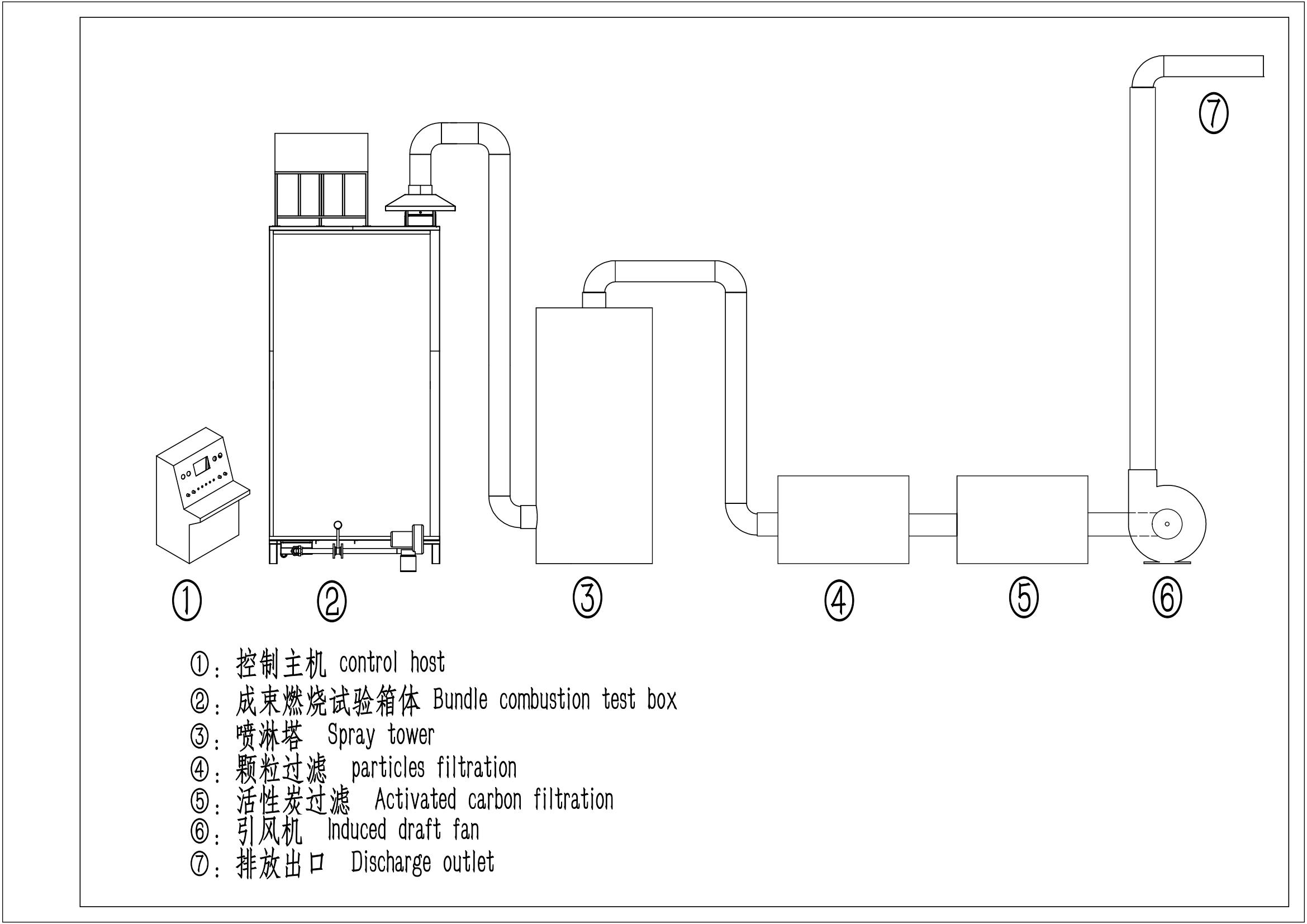

Huina Lako

ʻO ke keʻena ho'āʻo ahi, ka'ōnaehana hoʻomalu uila, ke kumu ea, ka'ōnaehana hoʻomalu holoʻana i ka punawai (propane gas and air compressed gas), ke alapiʻi kila, ka mea hoʻopau ahi, ka mea hoʻomaʻemaʻe emission, etc.

ʻĀpana ʻenehana

1.Working voltage: AC 220V±10% 50Hz,Power consumption: 2KW

2.The inlet and outlet air flow rate: 5000±200 L/min(adjustable)

3. Hoʻomaluʻia ka holoʻana o ka ea a me ka propane e ka pūnaewele mana.

4.Air kumu: propane (0.1Mpa), ea (0.1Mpa), mea kūʻai mai-no ka ea kumu.

5. Manawa manawa: 0 ~ 60min (hiki ke hoʻonohonoho)

6.Anemometer measurement range: 0 ~ 30m/s, measurement accuracy: ±0.2m/s

7. Ana keena ho'āʻo (mm): 2184(L) x 1156(W) x 5213(H)

Hoʻopiha ʻia me ka minerala me ke ahi-kūʻokoʻa i ka pōhaku huluhulu pōhaku, ma luna me 1500mm kiʻekiʻe palekana guardrail.

8.2 mau poʻo puhi puhi me ka hui hui Venturi

9. ʻO ka peʻahi inlet ea he haʻahaʻa haʻahaʻa vortex fan. Mālama ka PLC i ka wikiwiki o ka peʻahi ma o ka mea hoʻololi pinepine, a ʻo ka vortex flowmeter e ana i ka leo ea e loaʻa ai ka mana o ka lewa inlet volume.

10. Hoʻohana ka mea hoʻoheheʻe kiʻi i ka 4-72 anti-corrosion fan me ka nui o ka ea o 5000m2/h.

11.Flue kinoea ma hope o ka lapaʻau ʻana ua lako me kahi hale kiaʻi hoʻoneʻe lepo lepo me ka nui o ka ea o 5000 m.2/h

12. Loaʻa nā ʻano hana hoʻopau ahi nitrogen a me nā ʻano hana hoʻopau ahi no nā mea kūʻai aku e koho.

13. No ka hoao ana:

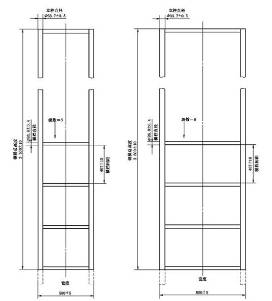

Ka nui o ke alapii kila maʻamau (mm): 500(W) x 3500(H)

Ka nui o ke alapii kila laula (mm): 800(W) x 3500(H)

14. Anana ili kuni (mm): 257(L) x 4.5(W)

15.Touch pale mana, intuitive a maopopo, uila ignition, 'akomi manawa.

16. Hoʻomaluʻia ka mea puhi ahi e PLC a hoʻohanaʻia e ka pale paʻi.

Mea hoao

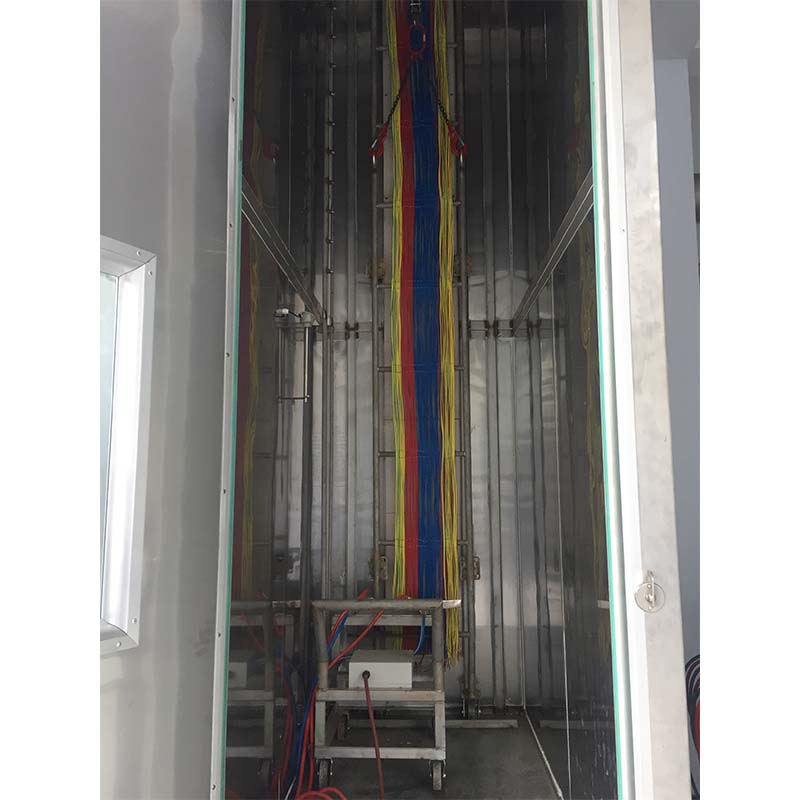

Test box: The experimental device should be a self-standing box with a width of 1000mm, a depth of 2000mm and a height of 4000mm. The bottom of the box should be 300mm above the ground. The perimeter of the test chamber should be sealed, the air from the bottom of the chamber from the front wall (150±10) mm to open a (800±20) mm x (400±10) mm air inlet into the box. A (300±30) mm x (1000±100) mm outlet should be opened at the back of the top of the chamber. Test chamber should be used on both sides of the heat transfer coefficient of about 0.7W.m-2.K-1 thermal insulation, the distance between the steel ladder and the back wall of the test chamber is (150±10) mm, and the bottom rung of the steel ladder is (400±5) mm from the ground. The lowest point of the cable sample is about 100mm from the ground.

-

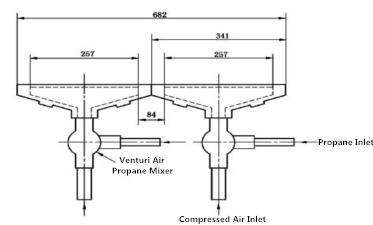

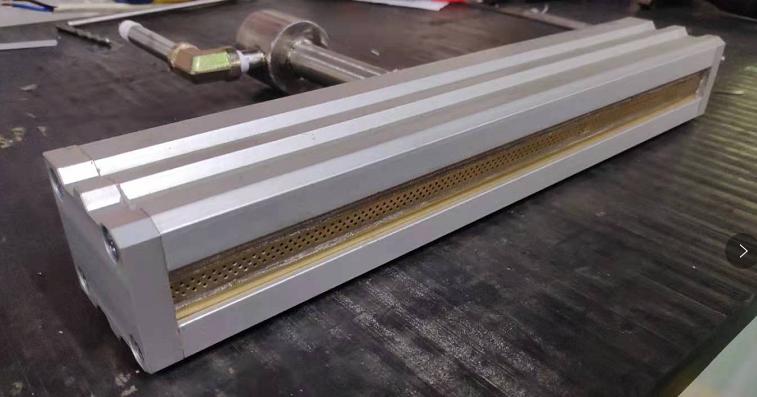

ʻO Venturi Blowtorch maʻamau

-

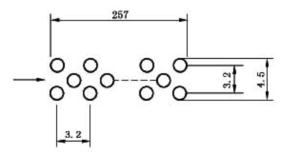

Puhi Puhi

-

Puhi ahi

-

Venturi hui

1.Anemometer: e ana i ka makani makani ma waho o ka piko o ke keʻena hoʻāʻo, inā ʻoi aku ka wikiwiki o ka makani ma mua o 8m/s a laila ʻaʻole hiki ke hoʻokō ʻia ka hoʻāʻo.

2. Temperature probe: ʻelua K-type thermocouples i hoʻolako ʻia ma nā ʻaoʻao ʻelua o ka pahu hoʻāʻo, inā ʻoi aku ka mahana o ka pā i loko ma lalo o 5 ℃ a i ʻole ke kiʻekiʻe ma mua o 40 ℃, ʻaʻole hiki ke hoʻokō ʻia ka hoʻāʻo.

3.Air source: adopt touch screen controller, frequency conversion control inlet axial flow fan, can intuitively read out and control the gas flow through the air box for (5000±200) L/min, stable air flow rate during the test.

4. Ma hope o ka pau ʻana o ka hoʻāʻo: Inā e ʻā mau ana ka hāpana ma hope o hoʻokahi hola o ka hoʻōki ʻana i ke ahi, hiki ke hoʻohana ʻia kahi mea hoʻoheheʻe wai a i ʻole nā mea kinai ahi e hoʻopau ai i ke ahi, a aia kahi funnel kūikawā no ka hoʻomaʻemaʻe ʻana i ke ahi. ʻōpala.

5.Steel ladder type: width (500±5)mm standard steel ladder, width (800±10)mm wide steel ladder, material for SUS304 stainless steel tube.

Hoʻokahi no nā alapiʻi kila maʻamau a ākea

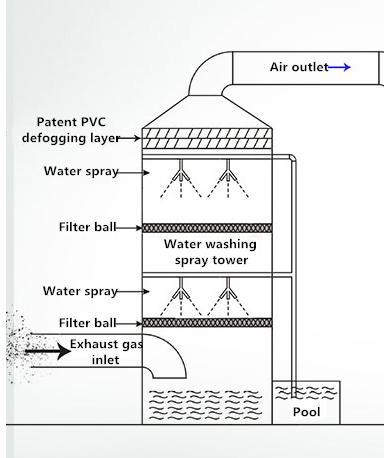

Mea Hoʻomaʻemaʻe Emission

ʻO ka ʻohi uahi a me ka holoi ʻana i nā mea hoʻoheheʻe: PP mea, me ke anawaena o 1500mm a me ke kiʻekiʻe o 3500mm. Ua māhele ʻia ka hale kiaʻi ohi uahi i ʻekolu mau ʻāpana: ka mea hoʻopuehu, ka uahi a me ka mea kānana lepo, a me ka mea hoʻopau uahi. Mea hoʻoheheʻe: e hoʻolako i ka wai no nā mea kānana kūikawā, e mālama i nā mea kānana kūikawā e kānana pono i ka uahi a me ka lepo. Ka uahi a me ka lepo kānana mea: Kānana ʻia e ka inu ʻana i nā mea kānana wai, hiki ke kānana maikaʻi i ka uahi a me ka lepo i hoʻokuʻu ʻia ka uahi keʻokeʻo. Hoʻohui nā mea kūʻai aku i nā lako palekana kaiapuni e like me ke kūlana.

-

Smoke Collection Tower Schematic

-

hale kiaʻi ʻohi uahi

-

Peʻahi huki hoʻokomo

Punawai ho'ā

1.Ignition source type: including one or two band-type propane gas blowtorches and their matching flowmeters and Venturi mixers. The ignition surface is drilled with 242 flat metal plates with a diameter of 1.32mm. The center distance of these holes is 3.2mm, arranged in three rows in a staggered arrangement, each row is 81, 80 and 81, distributed in the nominal size is 257×4.5mm. In addition, a row of small holes are opened on both sides of the flame board, and this guide hole can maintain the stable combustion of the flame.

2.Ignition source location: The torch should be placed horizontally, (75±5) mm from the front surface of the cable sample, (600±5) mm from the bottom of the test chamber, and symmetrical to the axis of the steel ladder. The flame supply point of the blowtorch should be located in the center between the two crossbeams of the steel ladder, and at least 500mm away from the lower end of the sample. The center line of the blowtorch system should be approximately the same as the center line of the steel ladder.

-

Vortex Flow Meter no

Ka Mana Pono o ka Volume Inlet Air -

Vortex air inlet fan

Luna Hooponopono Kahe Nui

Hoʻohana ʻia ka mea hoʻoponopono kahe nui no ke ana pololei a me ka mālama ʻana i ke kahe nui o ke kinoea. Loaʻa i nā mika kahe nui nā hiʻohiʻona o ka pololei kiʻekiʻe, ka hoʻihoʻi maikaʻi ʻana, ka pane wikiwiki, ka hoʻomaka palupalu, ka paʻa a me ka hilinaʻi, ka laulā hana ākea. Me nā mea hoʻohui maʻamau o ka honua, maʻalahi ka hana a hoʻohana, hiki ke hoʻokomo ʻia i kēlā me kēia kūlana, a maʻalahi hoʻi e hoʻopili me kahi kamepiula no ka mana maʻalahi.

Nā ʻāpana ʻenehana hoʻoponopono kahe nui:

1.Accuracy: ±2% F.S

2.Linearity:±1% F.S

3.Repeat accuracy:±0.2% F.S

4.Response time:1 ~ 4 sec

5.Pressure kū'ē: 3 Mpa

6.Working environment:5 ~ 45℃

7. Ke kumu hoʻokomo: 0- + 5v