LED Ultraviolet Irradiation Polyolefin Crosslinking Lako

Hōʻike huahana

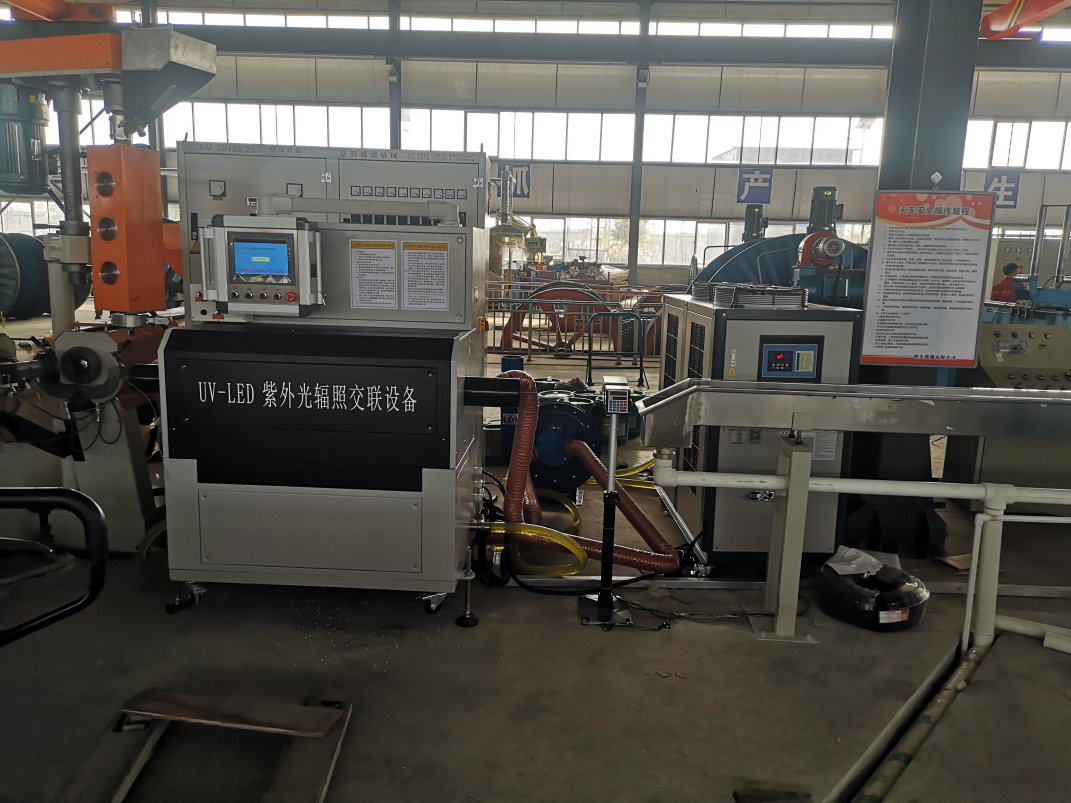

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

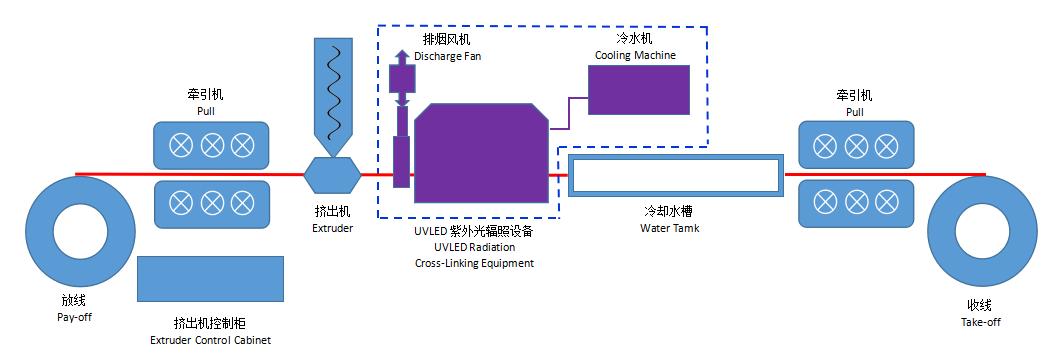

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Nā hiʻohiʻona

ʻO ka mea uila Ultraviolet ka mea kiʻekiʻe loa o ka ultraviolet radiation kumu ma ka honua, me ke kiʻekiʻe o ka ikehu (e pili ana i 30%), kiʻekiʻe kiʻekiʻe kiʻekiʻe hawewe lōʻihi koho (hapa-mana hawewe lōʻihi bandwidth 5nm), kiʻekiʻe loa lawelawe ola (30,000 hola), infrared Low wela. hanauna, ʻaʻohe hana ozone, ʻoi aku ka maikaʻi no ka hoʻōla ʻana i ka hoʻōla ʻana o ka polyolefin i hoʻopili ʻia a me nā mea ʻē aʻe.

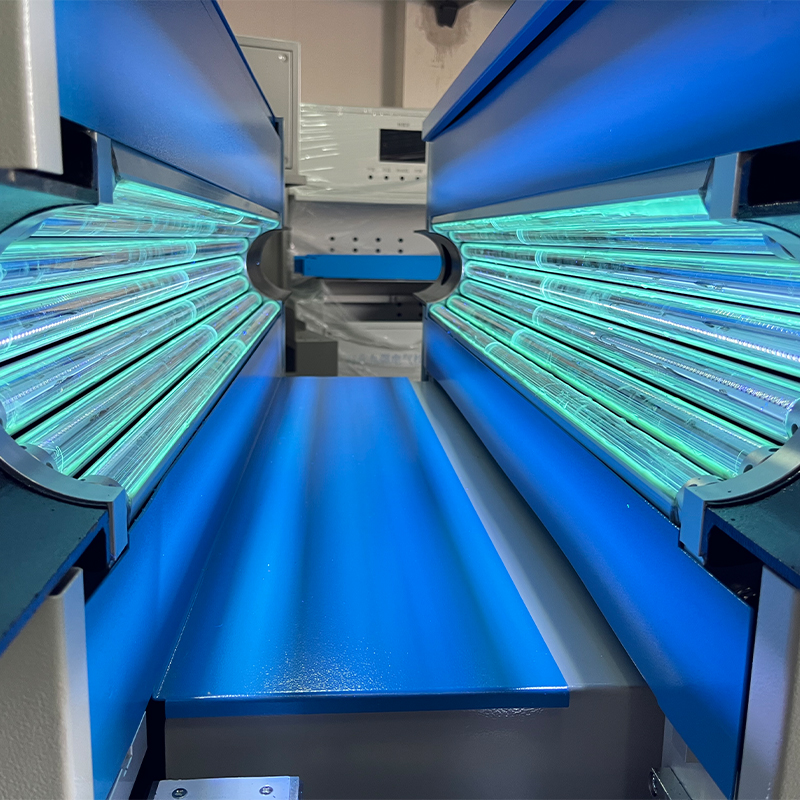

Ke hoʻohana nei ke kumu LED UV i kahi ʻano lens patented e hoʻomālamalama i ka ʻili o ke kaula i ʻoi aku ka like a me ka like. Hoʻokō ʻia ka hoʻolālā substrate e ka hui pū ʻana o ka Fluent software simulation fluid a me ka hoʻāʻo ʻana o ka mahana o ka hui LED, a ua hoʻolālā ʻia ka papa kaapuni LED e ka hui pū ʻana o ka alumini nitride ceramic a me ke kumu keleawe me ka hoʻomaʻamaʻa wela ʻoi aku ka maikaʻi. ʻōnaehana.

Ke hoʻohana nei ke kumu LED UV i kahi kumu mana pūnaewele puʻupuʻu e hoʻokele i ka LED UV. Hoʻopili ʻia ka mana hoʻokele kaʻa i loko o kahi kaʻina potting vacuum e hōʻoia i ka hilinaʻi o ka lako mana. I ka manawa like, hoʻohana ke ʻano o ka mana hoʻokele i kahi ʻāpana liʻiliʻi a lōʻihi, a ʻo ke kumu kukui LED ʻano lōʻihi e hoʻohana i kahi ʻano hoʻonohonoho hoʻi i hope no ke kaapuni LED e hōʻemi i ka lōʻihi o ka uea. E hoʻomaopopo i ke kumu o ke kukui e ʻā ana, e pio, a me nā hana ʻemi.

ʻO ka UV LED irradiation polyolefin cross-linking mea hana i kahi ʻāpana puʻupuʻu circular cavity tunnel, a ua hoʻolako ʻia me kahi kumu kukui LED ultraviolet e hana i kahi tunnel no ka hoʻomālamalama ʻana i ka ʻāpana waena, a hiki ke hoʻonohonoho ʻia ka mana o ka hāmeʻa i ka pae o 10. i 100%.

Ke hoʻohālikelike ʻia me nā mea hana kuʻuna mercury lamp type irradiation crosslinking (traditional transformer-driven UVI/UVII and electronic power-driven UVE-I), electron accelerator cross-linking, a me silane cross-linking, loaʻa iā ia nā pono penei:

1 Hoʻohana Haʻahaʻa i ka ikehu

ʻO UV LED irradiation polyolefin cross-linking lako i hoʻokomo ʻia ka mana like me ka 1/4 o nā mea hoʻonaninani ultraviolet mua, 1/30 o ka electron accelerator, ka wai a i ʻole ka wai wai e pono ai ka hoʻomehana lōʻihi, a ʻo ka hoʻohana ʻana i ka ikehu o ka wai hoʻomehana. kiʻekiʻe.

2 Manawa Pokole

Hoʻohana ka cross-linking i ke ʻano hoʻopili cross-linking extrusion pūnaewele e hōʻemi i ke kaʻina hana cross-linking ma hope, i hoʻohālikelike ʻia me ka manawa i koi ʻia no ka hoʻolapalapa ʻana a i ʻole ka mahu-kōkua ʻana i ka silane cross-linking a kauoha ʻia i ka hoʻoheheʻe ʻana i ka uila uila, mālama i ka manawa hana uea a me ke kaula. , ʻoi aku ka pilikia ʻO ka hoʻopau ʻana o ka misionari, he mea nui nā pōmaikaʻi.

3 Kumukuai Haahaa

Ke hoʻohālikelike ʻia me ka hoʻopili ʻana i ka wai mehana a me ka hoʻoili ʻana i ka electron beam irradiation, ua haʻahaʻa ke kumu kūʻai o ke kaula uila ultraviolet, a ua hoʻemi ʻia nā kaʻina hana paʻakikī i ke kaʻina hana, e like me ke kumukūʻai o ka lawe ʻana i nā kaula semi-finished a me nā kumukūʻai o ka mea hana.

4 ʻAʻohe Ozone

Kiʻekiʻe kiʻekiʻe hawewe koho, emits pono hawewe lōʻihi,ʻaʻohe infrared radiation, haʻahaʻa calorific waiwai; haʻahaʻa loa o ka pāhawewe ʻike ʻia, ʻaʻohe pollution māmā; ʻaʻohe hawewe ultraviolet pōkole pōkole, ʻaʻohe pōʻino i ke kino o ke kanaka, ʻaʻohe ozone emission. ʻAʻole pono no ka hoʻoheheʻe ʻana i ka ea uila, ʻaʻohe pono no ka hoʻokuʻu ʻana i ka wela a me ka ozone-discharging air duct, pono wale e hoʻopili i kahi paipu hoʻoheheʻe liʻiliʻi liʻiliʻi a me kahi peʻa 2kW e kāpae i ka uahi haʻahaʻa haʻahaʻa i hana ʻia i ka wā o ka insulation extrusion. . Kāohi i nā hopena o ka hoʻomālamalama māmā.

5 liʻiliʻi liʻiliʻi, maʻalahi e hoʻokomo

E hoʻohui wale i kahi mamao ma kahi o 2m ma waena o ka mold extruder laina hana mua a me ka pahu wai mahana, a kau i ka mīkini irradiation ma kahi ākea o 2.5 ~ 3 mau mika, a ʻoi aku paha. Hiki ke kau ʻia ka chiller ma kahi.

6 Maalahi e hana

ʻO ka wehe ʻana a me ka pani ʻana o ka tunnel, maʻalahi e hoʻomaʻemaʻe a hoʻohana i nā alakaʻi, maʻalahi e hana, ʻaʻohe kaʻina hana paʻakikī, hiki ke hoʻopau ʻia e ka mea hoʻohana extruder.

7 Ola lōʻihi a me ke kumu kūʻai mālama haʻahaʻa

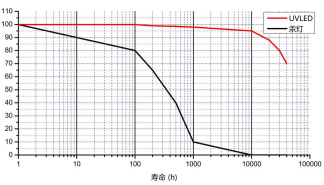

ʻO ke ola o nā polokalamu LED ma kahi o 30,000 mau hola, a ʻo ke ola o nā mea uila a me nā mea uila ʻē aʻe ʻaʻole i haʻahaʻa ma mua o ke ola o nā huahana uila a me nā huahana uila, me ka mālama ʻole ʻana. ʻO ka mālama mau ʻana e hoʻomaʻemaʻe i ka lens optical, ʻo nā mea hoʻohana ʻia nā holoi holoi ʻenehana a me nā mea hoʻomaʻemaʻe soot, hiki ke hana ʻia e ka mea hoʻohana. ʻO nā mea hoʻohana irradiation māmā maʻamau nā kukui UV a me nā mea hoʻonaninani, pono e hoʻololi ʻia i ka manawa pōkole. Pono pū ka ʻāpana uila uila e mālama i ka hui mālama.

8 Omaomao

ʻO ka Ambient Air Quality Standard (GB3095-2012) i ka Industrial Hygiene Standard e kuhikuhi ana i ka pae palekana ozone he 0.15ppm. ʻAʻole e hana nā mea hana crosslinking UVLED i ka ozone, ʻoiai nā lako kukui mercury kuʻuna e hoʻohua i ka nui o ka ozone. He kinoea kino ka Ozone.

1) Ka laulā o nā noi

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) Ke kumu kūʻai haʻahaʻa

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) maʻalahi e hoʻouka

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) hilinaʻi kiʻekiʻe

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Hoʻohālikelike i nā mea maikaʻi o ka LED irradiation cross-linking a me ka silane cross-linking:

|

LED ultraviolet irradiation mea lako |

ʻO nā mea hana hoʻohui Silane |

Mālama kālā |

|

|

Koina waiwai |

600 kg o ka ʻōpala no 90 extruders i kēlā me kēia makahiki |

12 tons o ka ʻōpala no 90 extruders i kēlā me kēia makahiki |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Mana extruder |

He liʻiliʻi ka viscosity o ka mea, liʻiliʻi ka hoʻohana ʻana i ka mana, a ʻo ka extrusion o 90 extruder he 30KW wale nō i ka wikiwiki holoʻokoʻa. |

ʻO ka viscosity kiʻekiʻe o ka mea, ka hoʻohana mana kiʻekiʻe, 90 KW piha wikiwiki extrusion pono |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Bila uila hana |

ʻAʻole pono e hoʻomaʻemaʻe i ka extruder |

E hoʻomaʻemaʻe i ka extruder no ka hapalua hola i kēlā me kēia lā |

Mālama iā 3400 USD i kēlā me kēia makahiki |

|

Uku hookui kea |

Ke lawe nei i 35 mau mika square ma ke ʻano he laʻana, ʻo ke kumukūʻai uila he 80KW no 30,000 mika. |

He laʻana he 35 mau mika square, he 4 mau hola no 30,000 mika o ka hoʻohui ʻana i ka mahu, a he 200KW o ka uila. |

Save about 7000 USD in electricity every year |

|

Huahana |

I ka manawa like me ka hoʻopili ʻana me ka extruder, hoʻopili pololei ʻia ka insulation extrusion me ka ʻole o ka hana lua. |

Hoʻomoʻa ʻia a hoʻomoʻa ʻia paha no ka liʻiliʻi o 4 mau hola (koi i kahi kahua kūikawā, mīkini hana mahu) |

Save 8400 USD per year |

|

ʻO ka maikaʻi o ka huahana |

ʻO ka emi ʻana o ka wela ma lalo o 4%, ʻaʻohe gel mua, ʻili maʻemaʻe |

ʻO ka emi ʻana o ka wela nui, ʻo ka hoʻokaʻawale ʻana i ka ʻāpana liʻiliʻi liʻiliʻi i loaʻa pinepine kahi ʻili maʻemaʻe ʻole a me kahi gel. |

|

|

Hoʻokomo waiwai |

Kauwaena |

Haʻahaʻa (lumi mahu a i ʻole loko mehana) |

|

|

Hoʻohana mana |

Haʻahaʻa (pono 10 KW wale nō) |

Kiʻekiʻe (koi i ka wela lōʻihi) |

|

|

Ke kumu kūʻai o ka hana |

Haʻahaʻa |

Kiʻekiʻe |

|

|

pōʻai hana |

Pōkole (pili kea pūnaewele) |

Ka lōʻihi (koi ka hana lua) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

ʻO ka hoʻohālikelike ʻana i nā pono o ka irradiation LED hou a me ka pilina pūnaewele me ke kukui mercury kiʻekiʻe kiʻekiʻe.

|

ʻO ka mīkini hoʻoheheʻe ultraviolet LED |

Kahiko kiʻekiʻe kiʻekiʻe mercury kukui irradiation mīkini |

|

|

Hoʻohana mana |

Ma lalo o 15 kW i kēlā me kēia hola |

80KW i kēlā me kēia hola |

|

ʻO ke kumukūʻai mālama |

Haʻahaʻa |

Kiʻekiʻe |

|

Ka wikiwiki hana |

Kiʻekiʻe |

Haʻahaʻa |

|

Ola kukui |

30000 hola |

400 hola |

|

Mea hoopau |

ʻAʻole |

Kukui, reflector, capacitor |

|

Huahana |

ʻAʻole kaupalena ka extruder i ka wikiwiki kiʻekiʻe a hiki ke hana ʻia ma ka hoʻohuli ʻana i ke kukui. |

ʻO ka wikiwiki o ka hana ʻana, haʻahaʻa haʻahaʻa, hoʻopau i ka hana, pono e hoʻomaʻamaʻa mua i ka hapalua hola ma mua |

|

Ka hana a me ka papahele papahele |

Hana maʻalahi, kapuaʻi liʻiliʻi, ʻaʻohe kali |

ʻO ka hana paʻakikī a me ka nui o ka papahele |

|

Mālama ʻo LED i ka mīkini uila hou i 34,000 USD nā koina uila. |

||

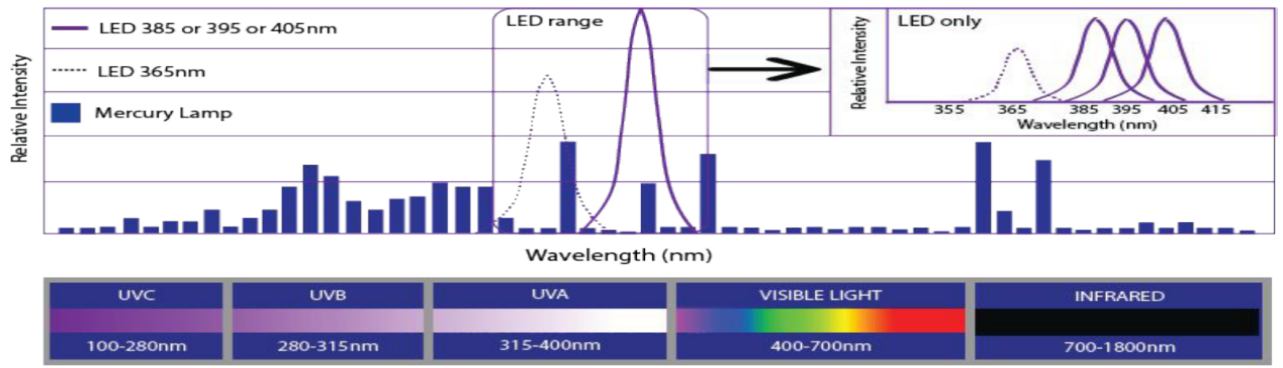

LED a me ke kukui mercury spectral contrast

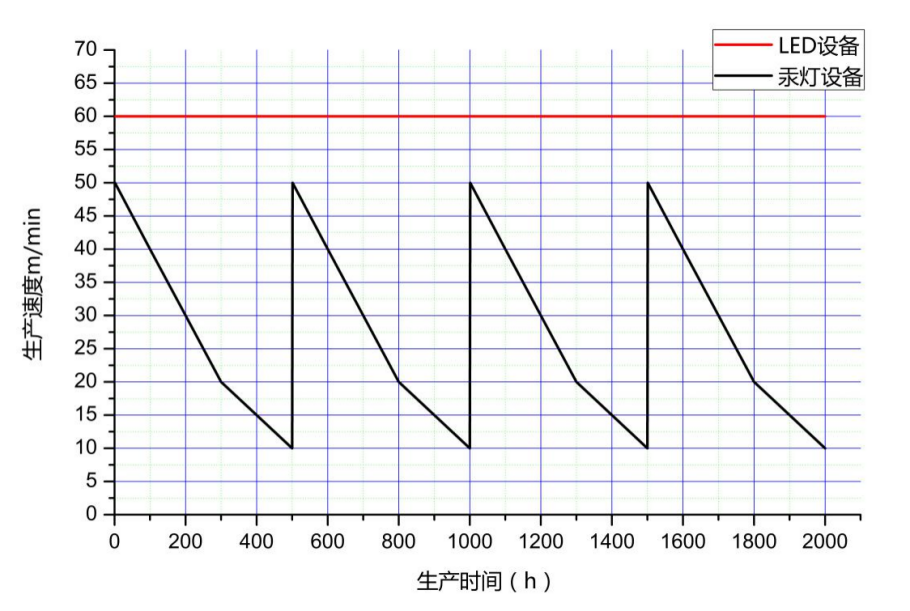

Hoʻohālikelike ke ola o ke kukui LED a me ka mercury

Ka hoʻohālikelike ʻana o ka wikiwiki o ka hana ma waena o nā lako kukui kukui mercury a me nā mea hoʻonaninani LED

UV-LED Iradiation Crosslinking Lako Hana Nā Parameters:

- 1. Mana: ʻekolu ʻāpana ʻelima uea (380V + N + honua)

- 2. Ka nui o ka mana mīkini i kau ʻia: 20kW

- 3. ʻO ke anawaena maikaʻi loa o ka wahi irradiation: 30mm

4. Ka lōʻihi o ka irradiation maikaʻi: 1m

- 5. Hoʻohana nā pahu kukui i ke kumu kukui i lawe ʻia mai i ka honua, hoʻohana ka lens i ka quartz i lawe ʻia mai, no laila he haʻahaʻa haʻahaʻa o ka ikehu, hoʻohana ke kukui i ka ʻenehana hoʻoheheʻe wai, i ʻoi aku ka lōʻihi o ke ola o ke kukui LED.

- 6. Hoʻohana ka mana mana i ka mana wai wai ʻo Taiwan Mingwei, i pale ʻia e ka ʻenehana potting vacuum, me ka overload, pōkole pōkole, over current, over voltage and over temperature protection.

7. Hiki ke hoʻololi i ka mana o ka Optical mai 10% -100%, e like me ka mea kūʻai aku e hoʻololi i kekahi mana.

- 7. ʻO ke ola kumu māmā: 30,000 mau hola (i hāʻawi ʻia e ka mea hana) Ua hoʻemi ʻia ka ikaika o ka mālamalama i ka 70% (e hāʻule ka maikaʻi i 70%). ʻO ka manawa hoʻohana he 30,000 mau hola, a ʻo ka manawa helu he 6 ~ 10 mau makahiki.

9. Ka nui o ka pahu iradiation: 1660mm * 960mm * 1730mm (lōʻihi x laula x kiʻekiʻe)

Nā hiʻohiʻona o nā lako hana:

- 1. ʻO ka wehe ʻana a me ka pani ʻana o ka tunnel, maʻalahi e hana a maʻemaʻe;

- 2. Ke hoʻohana nei i kahi pānaʻi hoʻopā kanaka-mīkini naʻauao, ka nānā ʻana i ka ʻikepili, a me nā hoʻonohonoho mana pihi hana e hoʻopau ʻia ma ka pā aniani;

- 3. Hoʻomaka ka hana hoʻomalu touchscreen a me ke pihi e noho kaʻawale;

- 4. Hoʻomaʻalili ʻia ke ʻano hoʻoluʻu e kahi chiller, a ua hana ʻia ka mea hoʻopulapula me kahi antifreeze kūikawā no nā kaʻa;

- 5. ʻO ka hana hoʻohemo ʻana i ka uahi waho, hoʻokuʻu ʻia ma ka ʻawaʻawa o waho

Hoʻolālā lako

Iecaianoaaiiuo wikiwiki o kea-pili polyethylene irradiated mea

|

Wahi 1

|

Wahi 2

|

Māhele 3

|

Māhele 4

|

Māhele 5

|

Poʻo mīkini |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²) |

ʻO ka mānoanoa nominal insulation (mm)

|

ʻO ka wikiwiki hana kūlohelohe (m / min)

|

Hoʻonui wela (%)

|

Deform mau loa |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Haʻahaʻa-smoke halogen-free irradiation mea hana wikiwiki

|

Wahi 1

|

Wahi 2

|

Māhele 3

|

Māhele 4

|

Māhele 5

|

Poʻo mīkini |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²)

|

ʻO ka mānoanoa nominal insulation (mm)

|

ʻO ka wikiwiki hana kūlohelohe (m / min)

|

Hoʻonui wela (%)

|

Deform mau loa |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Manaʻo: No ka mea ʻokoʻa nā mea extrusion a me nā kaʻina hana a me nā mea kelepona o nā ʻoihana like ʻole, ʻokoʻa ka wikiwiki extrusion. ʻAʻole kaupalena ka 90 extruder.

Hoʻokomo ʻia ma ka pūnaewele o LED ultraviolet irradiation cross-linking machine