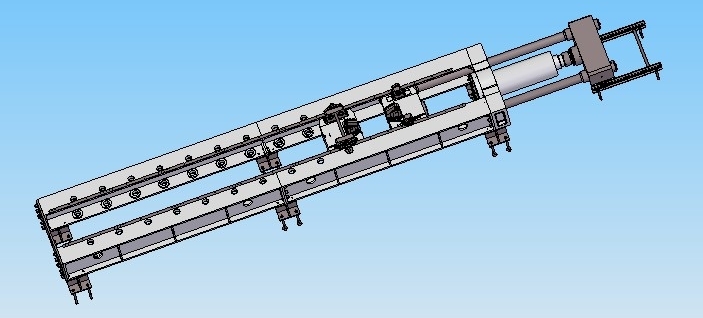

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Hōʻike huahana

ʻO TXWL-600 electro-hydraulic servo horizontal tensile testing machine e hoʻohana ana i ka hoʻolālā hoʻokalakupua, hoʻokahi koʻokoʻo pālua piston cylinder hoʻohana i ka ikaika hoʻāʻo, a ʻike ka ʻōnaehana kamepiula i ka mana maʻalahi o ke kaʻina hoʻāʻo ma o ka hoʻomalu ʻana i ka valve servo a me nā mea ʻē aʻe, ka hoʻāʻo. ʻohi pono ʻia ka ʻikepili e ka sensor hoʻoili a hoʻouna ʻia i ke kamepiula, e nānā pono ka ʻōnaehana, nā hana a mālama i nā hopena hoʻāʻo, a hiki i ka mea paʻi ke paʻi pololei i ka hōʻike hoʻāʻo i koi ʻia. Hoʻohana nui ʻia kēia mīkini no ka hoʻāʻo tensile o ke kaula uea kila, kahi hana hou o ka noiʻi ʻepekema a me ke aʻo ʻana a me nā ʻoihana ʻē aʻe e hoʻokō i nā koi o nā lako hoʻokolohua kūpono.

Wehewehe Mīkini

1. Pūnaehana hoʻokipa

ʻO ka ʻāpana mīkini koʻikoʻi ka nui o ka mīkini mīkini nui, ka noho ʻaila ʻaila, ka ʻaila ʻaila, ka lāʻau neʻe, ka noho mua a me ka hope chuck a me ka sensor haʻahaʻa. Hiki iā ia ke hana i ka hoʻāʻo tensile me ka haʻahaʻa kiʻekiʻe o 600kN ma ka hāpana.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Ua hoʻolakoʻia ka wahi ho'āʻo me kahi uhi pale, hiki ke pale pono i ka palekana o nā limahana ho'āʻo.

2.Oil source system

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Pauku Uila

Hoʻonohonoho ʻia ka mana uila ma ka wahi hana hoʻāʻo, a aia kahi papa hana i hoʻolālā ʻia e hoʻomaʻamaʻa i nā ʻano hana āpau i ka maka. ʻO nā ʻāpana uila o ka inoa kaulana honua, me ka hana paʻa a me ka maikaʻi hilinaʻi.

Pūnaehana polokalamu:

(1) Ma muli o ka papa hana Windows XP me nā hana hiki ke hoʻolālā ʻia, hiki ke hoʻohui ʻia i ka makemake e hoʻokō i nā koi o nā ʻano hoʻokolohua like ʻole. i ka palena kiʻekiʻe, a no ka hoʻomaopopo ʻana i ka hōʻike ʻikepili like ʻole, ke kaha kiʻi curve, ka hoʻoili ʻana i ka ʻikepili, ka mālama ʻana a me ka paʻi ʻana i nā hana i koi ʻia no ka hoʻāʻo.

(2) E hoʻouna i kahi hōʻailona mana i ka valve servo ma o ke kamepiula e hoʻomalu i ka wehe a me ke kuhikuhi o ka valve servo, a laila e hoʻomalu i ke kahe i loko o ka cylinder, a hoʻomaopopo i ka mana o ka ikaika ho'āʻo like-rate, equal-rate displacement, etc. .

(3) Hoʻolako ʻia me ʻelua mau puka mana hoʻopaʻa ʻia o ka ikaika hoʻāʻo a me ka neʻe ʻana.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Loaʻa i ka papa kuhikuhi nui nā hana a pau o ka hana i kēlā me kēia lā o ka hoʻāʻo, e like me ka hoʻokomo ʻana i ka ʻike hōʻike, ke koho laʻana, ke kaha kiʻi curve, ka hōʻike ʻikepili, ka hoʻoili ʻana i ka ʻikepili, ka ʻikepili ʻikepili, ka hana hoʻāʻo, a me nā mea ʻē aʻe. wikiwiki.

(6) Hiki ke hoʻopuka ʻia ka ʻikepili i ka mea paʻi e paʻi i ka hōʻike hōʻike.

(7) ʻO ka hoʻokele hierarchical ʻōnaehana, wehe ʻia nā ʻōnaehana ʻōnaehana i nā mea hoʻohana loea, e hōʻoia ana i ka maʻalahi a me ka hilinaʻi o ka ʻōnaehana.

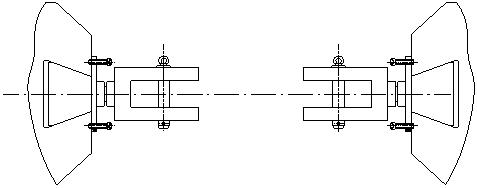

4. Ho'āʻo Mea Hana

Hoʻolakoʻia me nā mea ho'āʻo kaula kaula (e nānā i lalo) a me nā mea hana'ē aʻe i hanaʻia e like me ke kūlana i hāʻawiʻia e ka mea hoʻohana a iʻole nā koi tensile o ka hāpana.

5. Palekana Palekana

(1) Ka palekana o ka ho'āʻo inā ʻoi aku ka ikaika o ka hoʻāʻo ma mua o 2% a 5% o ka ikaika hoʻāʻo kiʻekiʻe a i ʻole ka waiwai i hoʻonohonoho ʻia.

(2) Ka pale ʻana i ka wā e neʻe ai ka piston i ke kūlana palena.

(3) Me ka mahana o ka aila, ka pae wai a me ka pale ʻana i ka aila a me nā mea hōʻike.

(4) He uhi pale ka wahi ho'āʻo e pale ai i ka hāʻule ʻana o ka hāpana.

(5) Ke hiki mai ka pilikia, e kaomi pololei i ke pihi hooki pilikia ma ke keena hoomalu

ʻĀpana ʻenehana

1.Maximum ho'āʻo ikaika: 600kN

2. Ho'āʻo ikaika ana laulā: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensile ho'āʻo wahi (koe piston hahau): 20mm ~ 12000mm

5. Piston hahau: 1000mm

6.Maximum hana wikiwiki o ka piston: 100 mm / min

7.Deformation extensometer pololei: 0.01mm

8. ʻO ka nui o ka mīkini nui (mm): 16000 (L) x 1300 (W) x 1000 (H) (koe i ka uhi pale)