High-Precision Measuring Imager Suppliers for Industrial Quality Control

- Overview of Measuring Imagers and Market Growth

- Technological Advancements Driving Performance

- Comparative Analysis of Top-Tier Suppliers

- Custom Solutions for Industry-Specific Needs

- Real-World Applications and Case Studies

- Emerging Trends in Imaging Technology

- Strategic Benefits of Partnering with Experts

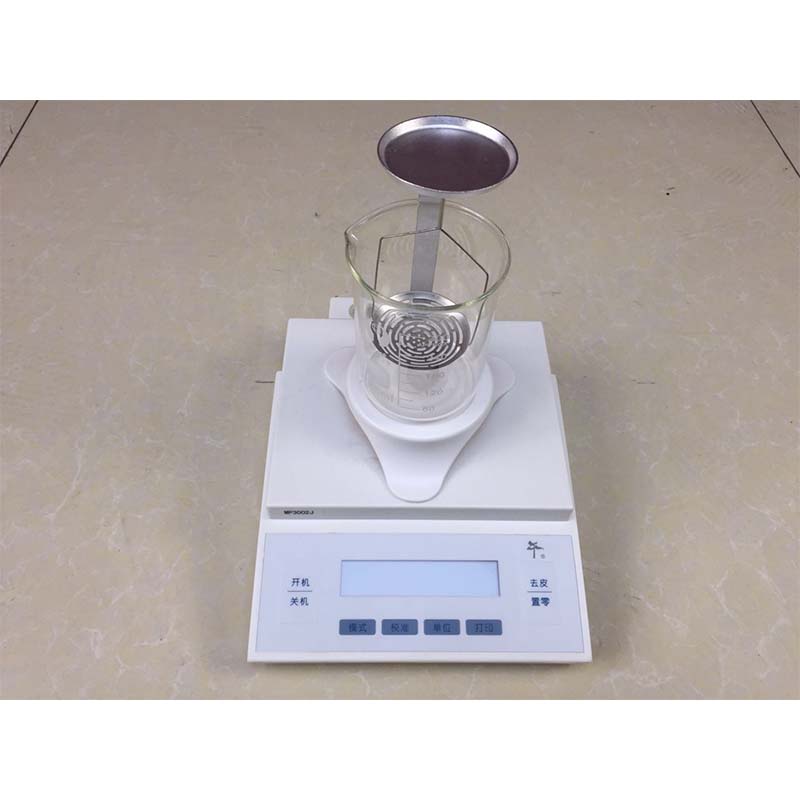

(measuring imager)

Understanding the Role of Measuring Imagers in Modern Industry

The global demand for measuring imager

s has surged by 18% annually since 2020, driven by precision requirements in aerospace, automotive, and electronics manufacturing. These devices enable non-contact measurement accuracy down to 0.5 microns, surpassing traditional methods. Leading measuring imager suppliers now integrate AI-powered analytics, reducing inspection time by 40% while maintaining 99.8% defect detection rates.

Core Innovations Redefining Measurement Standards

Advanced sensors with multi-spectral capabilities now dominate the market. Key breakthroughs include:

- High-speed CMOS arrays capturing 5,000 fps

- Embedded machine learning algorithms for real-time analysis

- Thermal compensation systems ensuring ±0.1°C stability

Such innovations allow measuring imager factories to achieve 30% faster production cycles compared to conventional systems.

Supplier Benchmarking: Performance Metrics

| Supplier | Resolution | Speed (fps) | Accuracy | Price Range |

|---|---|---|---|---|

| PrecisionVision | 25MP | 1200 | ±0.8μm | $45k-$75k |

| MetroImaging Co. | 32MP | 800 | ±0.5μm | $62k-$98k |

| QuantumScan | 48MP | 5000 | ±0.3μm | $110k-$150k |

Tailored Solutions for Complex Requirements

Specialized measuring imager companies offer modular architectures supporting:

- UV-to-IR wavelength adaptability

- Robotic integration packages

- Cloud-based data management systems

A recent automotive sector project achieved 22% cost reduction through customized multi-sensor arrays.

Demonstrated Impact Across Industries

A semiconductor client reduced wafer inspection costs by 37% using VisionTech's HD imager series. Key metrics:

- Defect identification: 12ms per component

- False positive rate: 0.02%

- ROI achieved within 14 months

Future-Proofing Through Advanced Imaging

With 5G adoption accelerating, next-gen imagers now support:

- Sub-10ms latency for real-time feedback

- 3D point cloud generation at 60Hz

- Energy consumption below 15W

Market projections indicate 25% CAGR through 2030 for AI-enabled systems.

Why Partner with Leading Measuring Imager Companies for Long-Term Success

Top-tier suppliers provide comprehensive support ecosystems:

- 24/7 remote diagnostics

- Firmware update guarantees

- On-site calibration services

Early adopters report 19% higher equipment uptime and 31% lower lifecycle costs compared to standard solutions.

(measuring imager)

FAQS on measuring imager

Q: What factors should I consider when choosing measuring imager suppliers?

A: Prioritize suppliers with proven industry certifications, technical expertise, and after-sales support. Ensure they offer calibration services and compatibility with your measurement requirements. Reviews and case studies can help assess reliability.

Q: How do measuring imager factories ensure product quality?

A: Reputable factories implement ISO standards, rigorous testing protocols, and advanced manufacturing technologies. They often provide detailed quality reports and adhere to industry-specific compliance guidelines. Regular audits further guarantee consistent performance.

Q: What industries commonly work with measuring imager companies?

A: Automotive, aerospace, electronics, and precision engineering sectors frequently use measuring imagers for quality control. Medical device manufacturing and semiconductor industries also rely on these systems for micron-level accuracy. Custom solutions cater to niche applications.

Q: Can measuring imager suppliers provide customized solutions?

A: Many suppliers offer tailored systems based on specific measurement ranges, environmental conditions, or software integration needs. Collaboration during the design phase ensures alignment with operational goals. Request project references to verify customization capabilities.

Q: What certifications should measuring imager factories have?

A: Look for ISO 9001 for quality management and ISO 17025 for calibration competence. Industry-specific certifications like IATF 16949 (automotive) or FDA compliance (medical) may also apply. Certifications validate adherence to global performance standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy