1月 . 14, 2025 11:03

Back to list

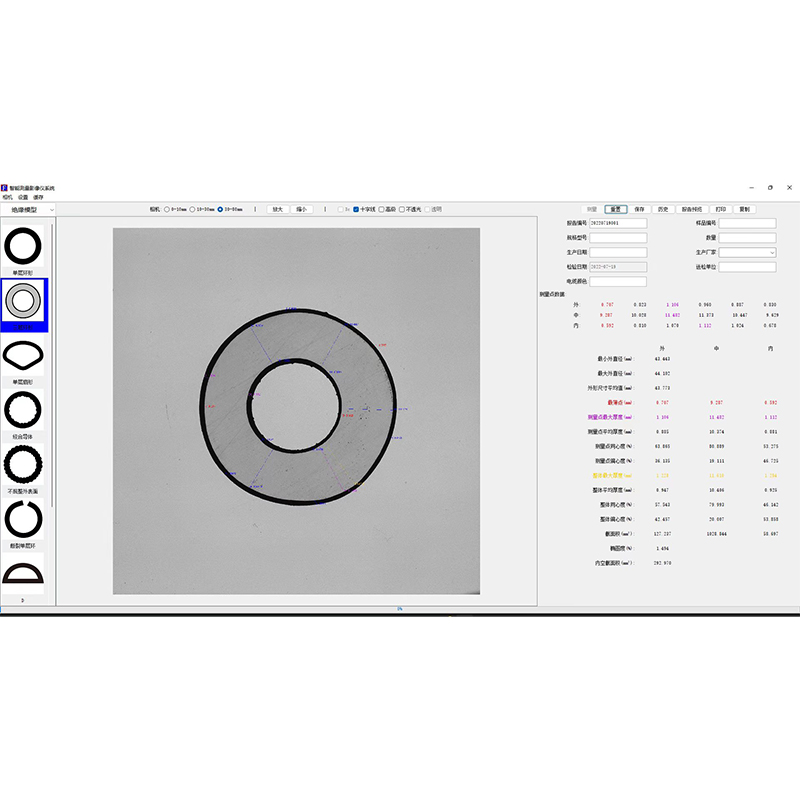

FYBD-I Semi-Conductive Shielding Rubber And Plastic Material Volume Resistivity Intelligent Tester

Electronic tensile testers have revolutionized the way we understand and measure material properties. These sophisticated devices are paramount in various industries, offering unparalleled precision and repeatability in testing material strength and behavior. With a deep foundation in materials science and engineering, electronic tensile testers have become the quintessential tool for manufacturers, researchers, and quality assurance teams across the globe.

The authoritativeness of electronic tensile testers is underscored by their widespread adoption in critical industry sectors like aerospace, automotive, construction, and biomedical engineering. These sectors demand the highest levels of precision and reliability, and electronic tensile testers deliver by meeting rigorous industry standards and international testing protocols, such as ASTM and ISO. The conformity to these standards establishes the tester's credibility and assures end-users that the equipment is designed to provide reliable and authoritative data essential for decision-making and regulatory compliance. Trustworthiness is a cornerstone of the value offered by electronic tensile testers. Manufacturers and suppliers of these devices have cultivated a reputation for producing robust, long-lasting machines backed by comprehensive warranties and dedicated customer support. Moreover, the integration of cutting-edge technology such as load cells, extensometers, and software analytics ensures that the data produced is trustworthy and can withstand scrutiny in scientific and industrial contexts. Transparency in calibration, maintenance requirements, and performance metrics also adds to the trust users place in these devices. In summary, electronic tensile testers are indispensable tools that embody experience, expertise, authoritativeness, and trustworthiness. They equip industries with the ability to rigorously test materials, leading to innovations that enhance safety, performance, and compliance. As technological advances continue, the future of electronic tensile testing looks promising, with enhancements in data analytics, machine learning, and adaptability poised to further strengthen their role in material science.

The authoritativeness of electronic tensile testers is underscored by their widespread adoption in critical industry sectors like aerospace, automotive, construction, and biomedical engineering. These sectors demand the highest levels of precision and reliability, and electronic tensile testers deliver by meeting rigorous industry standards and international testing protocols, such as ASTM and ISO. The conformity to these standards establishes the tester's credibility and assures end-users that the equipment is designed to provide reliable and authoritative data essential for decision-making and regulatory compliance. Trustworthiness is a cornerstone of the value offered by electronic tensile testers. Manufacturers and suppliers of these devices have cultivated a reputation for producing robust, long-lasting machines backed by comprehensive warranties and dedicated customer support. Moreover, the integration of cutting-edge technology such as load cells, extensometers, and software analytics ensures that the data produced is trustworthy and can withstand scrutiny in scientific and industrial contexts. Transparency in calibration, maintenance requirements, and performance metrics also adds to the trust users place in these devices. In summary, electronic tensile testers are indispensable tools that embody experience, expertise, authoritativeness, and trustworthiness. They equip industries with the ability to rigorously test materials, leading to innovations that enhance safety, performance, and compliance. As technological advances continue, the future of electronic tensile testing looks promising, with enhancements in data analytics, machine learning, and adaptability poised to further strengthen their role in material science.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy