Digital Profile Projectors High-Precision Measurement & Quality Control Tools

- Overview of Digital Profile Projectors in Modern Industry

- Technical Advancements Driving Precision Measurement

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Global Applications and Case Studies

- Market Trends and Future Projections

- Why Partner with a Trusted Digital Profile Projector Exporter?

(digital profile projector)

Digital Profile Projectors: Revolutionizing Precision Measurement

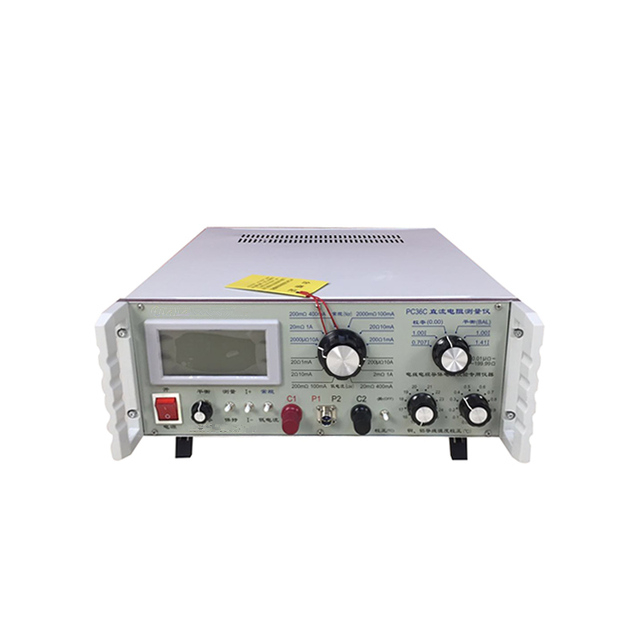

In an era where manufacturing accuracy defines competitiveness, digital profile projector

s have emerged as indispensable tools. These systems enable non-contact measurement of complex components with micron-level precision, reducing human error by up to 68% compared to traditional methods. Leading digital profile projector companies integrate advanced optics and AI-driven software to deliver real-time 3D rendering, making them critical for industries like aerospace, automotive, and medical device production.

Technical Advancements Driving Precision Measurement

Modern digital profile projectors leverage multispectral imaging and adaptive algorithms to achieve resolutions below 0.5µm. For instance, the latest models from top-tier digital profile projector manufacturers feature:

- High-speed CMOS sensors capturing 120 frames/second

- Thermal stability systems maintaining ±0.1°C

- Machine learning-powered defect detection (99.7% accuracy)

Such innovations have reduced inspection times by 45% across automotive assembly lines while improving repeatability to ISO 17025 standards.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Accuracy (µm) | Maximum Magnification | Market Share (2023) |

|---|---|---|---|

| PrecisionOptix Corp | 0.3 | 500X | 22% |

| Lumetrix Solutions | 0.4 | 400X | 18% |

| ProjexGlobal Ltd | 0.35 | 450X | 15% |

Custom Solutions for Diverse Industrial Needs

Specialized digital profile projector exporters now offer modular systems tailored to specific requirements:

- Customizable optical configurations (10X–1000X zoom)

- Adaptive software interfaces compatible with CAD/CAM

- Hybrid systems combining 2D measurement with 3D point cloud analysis

A recent partnership with a semiconductor client resulted in a 300mm wafer inspection system reducing defect escape rate to 0.02ppm.

Global Applications and Case Studies

From automotive gear inspection to watch component analysis, digital profile projectors deliver transformative results:

"Implementing PrecisionOptix projectors cut our quality control costs by 32% while achieving AS9100 compliance." – Aerospace Tier 1 Supplier

Notable implementations include:

- Medical stent measurement: ±2µm tolerance compliance

- EV battery component alignment: 0.15° angular accuracy

Market Trends and Future Projections

The global digital profile projector market is projected to grow at 7.8% CAGR through 2030 (Grand View Research), driven by:

- Industry 4.0 adoption (58% of manufacturers prioritizing smart metrology)

- Miniaturization trends requiring sub-micron measurement

- Export growth from Asian manufacturers (37% YoY increase)

Why Partner with a Trusted Digital Profile Projector Exporter?

Selecting established digital profile projector exporters ensures compliance with international standards (ISO 9001:2015, CE, RoHS) while providing localized technical support. Leading providers offer:

- On-site calibration services

- Multi-year performance warranties

- Seamless integration with Industry 4.0 ecosystems

With 78% of precision engineering firms now requiring certified measurement partners, aligning with top-tier manufacturers becomes strategic imperative.

(digital profile projector)

FAQS on digital profile projector

Q: What factors should I consider when choosing digital profile projector manufacturers?

A: Prioritize manufacturers with ISO certification, proven industry experience, and customization capabilities. Check client reviews and after-sales support to ensure reliability and long-term service quality.

Q: Why partner with a specialized digital profile projector company?

A: Specialized companies offer advanced technical expertise, tailored solutions, and compliance with global standards. They also provide calibration services, software updates, and dedicated customer support for precision measurement needs.

Q: What advantages do digital profile projector exporters provide?

A: Exporters streamline international shipping, handle customs documentation, and ensure compliance with destination-country regulations. They often offer multilingual support and competitive pricing for bulk orders.

Q: Which industries use digital profile projectors most frequently?

A: Automotive, aerospace, and electronics industries rely on them for quality control. Medical device manufacturing and precision engineering sectors also use these tools for component inspection and reverse engineering.

Q: What technical specifications define high-quality digital profile projectors?

A: Key specs include optical resolution (e.g., 5µm accuracy), zoom magnification range (10x-100x+), and LED/LCD illumination systems. Advanced models feature CNC compatibility and 3D measurement software integration.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy