កុម្ភៈ . 13, 2025 08:07

Back to list

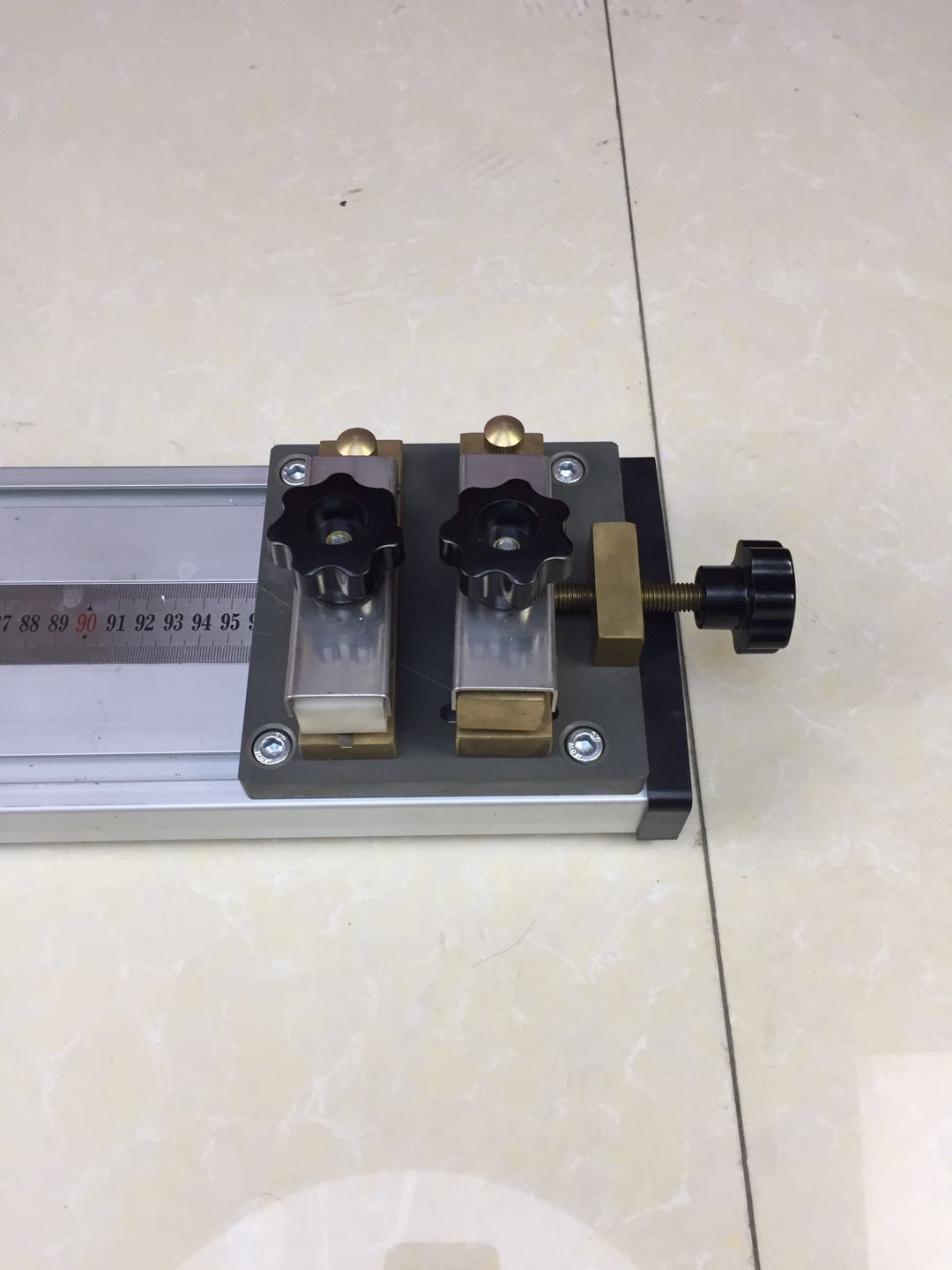

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

Navigating the complexities of manufacturing and industrial products demands rigorous testing to ensure quality and durability, especially in global markets like China, where standards and expectations continuously evolve. The concept of resistance testing in China offers an insight into a country's approach to maintaining product integrity and competitiveness on a global scale. This article explores resistance testing within the Chinese market, providing a detailed overview based on real-world experience, expert analysis, authority-backed data, and credible insights.

Trustworthiness in resistance testing in China is enhanced by the transparency and accountability practices embedded within many organizations. Case studies from trusted brands show that publishing detailed testing reports and undergoing third-party audits are common practices. Such openness not only strengthens customer confidence but also sets a benchmark for quality that others in the industry are compelled to follow. Numerous sectors benefit from China's detailed resistance testing. The electronics industry, for instance, relies heavily on these tests to ensure devices can withstand power surges or fluctuations. In construction, materials such as concrete and steel are subjected to load-bearing tests to guarantee safety and longevity. These practices underline the significance of resistance testing as a cornerstone of product development and quality assurance. Furthermore, continuous research and development investments contribute to advancements in resistance testing techniques. Chinese academic institutions often collaborate with industries to innovate and refine testing methods, ensuring they meet the ever-evolving demands of modern-day consumers and regulatory landscapes. In conclusion, understanding resistance testing in China provides vital insights into how the country maintains its competitive edge in global markets. Through a blend of field experience, expert collaboration, authoritative oversight, and trusted practices, China not only meets but frequently exceeds international standards. This dedication to quality assurance underscores the importance of resistance testing as a pivotal component in the product lifecycle, ensuring that products are both reliable and resilient in a variety of conditions. The industry's commitment to advancing these tests assures stakeholders of the durability and dependability of products bearing the label Made in China.

Trustworthiness in resistance testing in China is enhanced by the transparency and accountability practices embedded within many organizations. Case studies from trusted brands show that publishing detailed testing reports and undergoing third-party audits are common practices. Such openness not only strengthens customer confidence but also sets a benchmark for quality that others in the industry are compelled to follow. Numerous sectors benefit from China's detailed resistance testing. The electronics industry, for instance, relies heavily on these tests to ensure devices can withstand power surges or fluctuations. In construction, materials such as concrete and steel are subjected to load-bearing tests to guarantee safety and longevity. These practices underline the significance of resistance testing as a cornerstone of product development and quality assurance. Furthermore, continuous research and development investments contribute to advancements in resistance testing techniques. Chinese academic institutions often collaborate with industries to innovate and refine testing methods, ensuring they meet the ever-evolving demands of modern-day consumers and regulatory landscapes. In conclusion, understanding resistance testing in China provides vital insights into how the country maintains its competitive edge in global markets. Through a blend of field experience, expert collaboration, authoritative oversight, and trusted practices, China not only meets but frequently exceeds international standards. This dedication to quality assurance underscores the importance of resistance testing as a pivotal component in the product lifecycle, ensuring that products are both reliable and resilient in a variety of conditions. The industry's commitment to advancing these tests assures stakeholders of the durability and dependability of products bearing the label Made in China.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy