មីនា . 06, 2025 11:47

Back to list

tensile tester grips manufacturers

Tensile tester grips play an essential role in the field of material science and mechanical testing. As components that directly interface with the specimen, their quality, design, and adaptability are crucial for accurate testing results. With growing demand for reliable and versatile testing solutions, selecting a proficient manufacturer for tensile tester grips becomes paramount. Here’s an insightful guide into what sets the leading tensile tester grip manufacturers apart.

Innovative manufacturing techniques are a hallmark of trustworthy manufacturers. By leveraging state-of-the-art technology such as CNC machining and 3D modeling, these companies produce grips with high precision and efficiency. This not only enhances the grip's functional performance but also extends its longevity, ensuring an optimal return on investment. A strong customer support system further distinguishes top manufacturers. They provide expert consultations to help select the appropriate grip for specific testing applications and offer guidance on setup and maintenance to maximize efficiency and lifespan. Moreover, these manufacturers offer warranties and have a responsive service team ready to address post-purchase inquiries, which reinforces client trust and satisfaction. Manufacturers also demonstrate their reliability through extensive case studies and testimonials. Sharing success stories and empirical results from customer projects showcases not only their product's capabilities but also their ability to solve complex testing challenges. These narratives are potent indicators of a manufacturer's reputation and reliability. Lastly, environmental considerations reflect the ethos of a progressive manufacturer. Those committed to sustainability focus on reducing waste and employing eco-friendly materials where possible. By associating with manufacturers who prioritize sustainability, organizations can align their testing practices with broader environmental goals. When selecting a tensile tester grips manufacturer, prioritizing experience, expertise, authoritativeness, and trustworthiness ensures that you partner with a company that meets the demands of modern testing environments. These qualities guarantee that the products you invest in will not only deliver precise and reliable results but also enhance your overall testing capabilities. As industries continue to push the boundaries of material properties, the role of dependable manufacturers becomes even more critical, driving innovation and setting new standards in tensile testing technology.

Innovative manufacturing techniques are a hallmark of trustworthy manufacturers. By leveraging state-of-the-art technology such as CNC machining and 3D modeling, these companies produce grips with high precision and efficiency. This not only enhances the grip's functional performance but also extends its longevity, ensuring an optimal return on investment. A strong customer support system further distinguishes top manufacturers. They provide expert consultations to help select the appropriate grip for specific testing applications and offer guidance on setup and maintenance to maximize efficiency and lifespan. Moreover, these manufacturers offer warranties and have a responsive service team ready to address post-purchase inquiries, which reinforces client trust and satisfaction. Manufacturers also demonstrate their reliability through extensive case studies and testimonials. Sharing success stories and empirical results from customer projects showcases not only their product's capabilities but also their ability to solve complex testing challenges. These narratives are potent indicators of a manufacturer's reputation and reliability. Lastly, environmental considerations reflect the ethos of a progressive manufacturer. Those committed to sustainability focus on reducing waste and employing eco-friendly materials where possible. By associating with manufacturers who prioritize sustainability, organizations can align their testing practices with broader environmental goals. When selecting a tensile tester grips manufacturer, prioritizing experience, expertise, authoritativeness, and trustworthiness ensures that you partner with a company that meets the demands of modern testing environments. These qualities guarantee that the products you invest in will not only deliver precise and reliable results but also enhance your overall testing capabilities. As industries continue to push the boundaries of material properties, the role of dependable manufacturers becomes even more critical, driving innovation and setting new standards in tensile testing technology.

Latest news

-

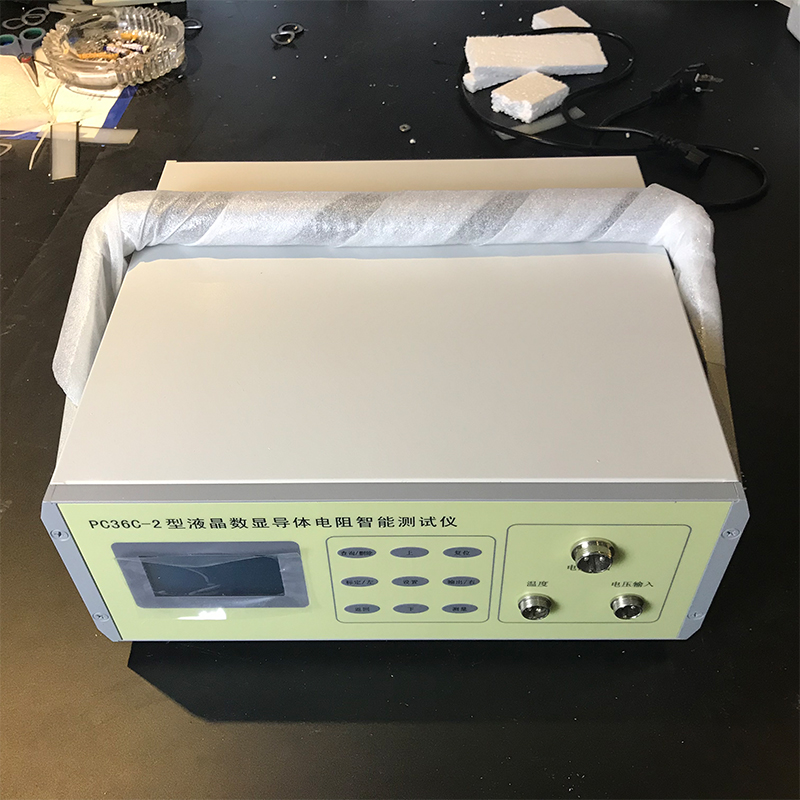

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy