2월 . 13, 2025 21:46

Back to list

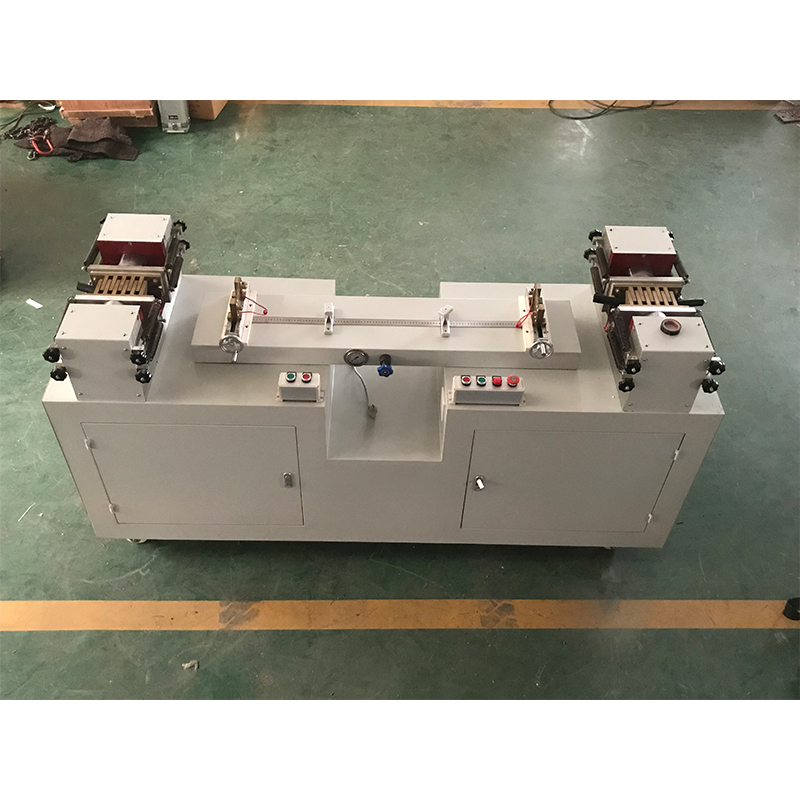

china 1000 pounds force tensile tester

Exploring the Latest Innovations in China’s 1000 Pounds Force Tensile Tester

Chinese manufacturers have positioned themselves as leaders in tensile testing by investing in research and development. Collaborations with international testing bodies and adherence to global standards underscore their commitment to producing top-tier testing apparatus. These collaborations have not only improved product quality but have also instilled a sense of trust among global clients. Authoritativeness through Accredited Performance Achieving compliance with international standards such as ASTM and ISO is a crucial factor for any tensile testing equipment, and China's 1000 pounds force models excel in this regard. Rigorous quality checks and certifications authenticate their performance and reliability, making them authoritative tools for materials analysis. Reliability in Diverse Testing Applications The 1000 pounds force tensile tester’s reliability stretches across diverse applications, serving as an invaluable asset in quality control and research development. From assessing the elongation and fracture points of new polymers to ensuring the tensile strength of construction materials, these testers are integral to innovation and safety. Real Experience Testimonials from Industry Professionals Engineers and quality control managers have attested to the transformative impact of these testers. One construction materials engineer remarked, “Switching to the Chinese 1000 pounds force tensile tester streamlined our testing processes and significantly reduced downtime. The precision is unmatched.” Conclusion Setting the Benchmark in Material Analysis China’s 1000 pounds force tensile testers exemplify the blend of affordability, precision, and durability, effectively setting a benchmark in material testing technology. As industries strive for innovation while maintaining stringent quality standards, these testers will continue to play a pivotal role in material evaluation and product development. Incorporating these advanced instruments into testing protocols not only enhances accuracy but also reinforces a commitment to quality, providing a competitive edge in today’s demanding market landscape.

Chinese manufacturers have positioned themselves as leaders in tensile testing by investing in research and development. Collaborations with international testing bodies and adherence to global standards underscore their commitment to producing top-tier testing apparatus. These collaborations have not only improved product quality but have also instilled a sense of trust among global clients. Authoritativeness through Accredited Performance Achieving compliance with international standards such as ASTM and ISO is a crucial factor for any tensile testing equipment, and China's 1000 pounds force models excel in this regard. Rigorous quality checks and certifications authenticate their performance and reliability, making them authoritative tools for materials analysis. Reliability in Diverse Testing Applications The 1000 pounds force tensile tester’s reliability stretches across diverse applications, serving as an invaluable asset in quality control and research development. From assessing the elongation and fracture points of new polymers to ensuring the tensile strength of construction materials, these testers are integral to innovation and safety. Real Experience Testimonials from Industry Professionals Engineers and quality control managers have attested to the transformative impact of these testers. One construction materials engineer remarked, “Switching to the Chinese 1000 pounds force tensile tester streamlined our testing processes and significantly reduced downtime. The precision is unmatched.” Conclusion Setting the Benchmark in Material Analysis China’s 1000 pounds force tensile testers exemplify the blend of affordability, precision, and durability, effectively setting a benchmark in material testing technology. As industries strive for innovation while maintaining stringent quality standards, these testers will continue to play a pivotal role in material evaluation and product development. Incorporating these advanced instruments into testing protocols not only enhances accuracy but also reinforces a commitment to quality, providing a competitive edge in today’s demanding market landscape.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy