Jan . 24, 2025 04:51

Back to list

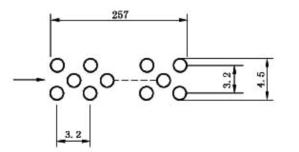

LED Ultraviolet Irradiation Polyolefin Crosslinking Equipment

In the world of custom coaxial cables, precision and quality are paramount. The key to achieving these is the use of a quality custom coaxial cable slicer. This indispensable tool transforms raw coaxial cables into perfectly sliced components, ensuring optimal performance for a wide range of applications from telecommunications to high-frequency data transmission. As a seasoned expert in this field, I bring years of accumulated experience and insights that highlight the significance of custom coaxial cable slicers.

Authority in this domain also comes from continuous advancements and compliance with industry standards. Top manufacturers of custom coaxial cable slicers ensure that their products meet rigorous quality certifications and standards, such as ISO 9001 and OSHA compliance, ensuring users receive a reliable and safe product. Staying abreast of technological advancements further fortifies our product's position in providing unparalleled quality and efficiency. Trustworthiness is built through consistent performance and results. Testimonials and success stories from industry professionals underline the reliability of a high-quality coaxial cable slicer. Feedback from telecom industry specialists, who regularly rely on these tools for maintaining optimal signal integrity, highlights the trust placed in these devices. Informed procurement decisions, backed by substantial research and recommendations, further bolster the credibility and reliability of custom slicers in this competitive market. The journey through the purchase and utilization of a custom coaxial cable slicer is significantly influenced by the assurance of robust support and service from manufacturers. Providing training resources and customer support fortifies user confidence. Troubleshooting guides, dedicated helplines, and regular updates ensure that clients can maximize the utility of their devices, leading to enhanced productivity and satisfaction. In conclusion, the importance of a custom coaxial cable slicer in delivering unparalleled performance and reliability cannot be overstated. From the nuanced understanding of cable anatomy and slicing mechanics to the trust earned through consistent product excellence, every aspect contributes to creating cables capable of supporting the world's intricate data networks. By leveraging expertise, authority, and trust, a custom coaxial cable slicer empowers industries with the precision needed to excel in a rapidly evolving technological landscape, ensuring they remain at the forefront of innovation and efficiency.

Authority in this domain also comes from continuous advancements and compliance with industry standards. Top manufacturers of custom coaxial cable slicers ensure that their products meet rigorous quality certifications and standards, such as ISO 9001 and OSHA compliance, ensuring users receive a reliable and safe product. Staying abreast of technological advancements further fortifies our product's position in providing unparalleled quality and efficiency. Trustworthiness is built through consistent performance and results. Testimonials and success stories from industry professionals underline the reliability of a high-quality coaxial cable slicer. Feedback from telecom industry specialists, who regularly rely on these tools for maintaining optimal signal integrity, highlights the trust placed in these devices. Informed procurement decisions, backed by substantial research and recommendations, further bolster the credibility and reliability of custom slicers in this competitive market. The journey through the purchase and utilization of a custom coaxial cable slicer is significantly influenced by the assurance of robust support and service from manufacturers. Providing training resources and customer support fortifies user confidence. Troubleshooting guides, dedicated helplines, and regular updates ensure that clients can maximize the utility of their devices, leading to enhanced productivity and satisfaction. In conclusion, the importance of a custom coaxial cable slicer in delivering unparalleled performance and reliability cannot be overstated. From the nuanced understanding of cable anatomy and slicing mechanics to the trust earned through consistent product excellence, every aspect contributes to creating cables capable of supporting the world's intricate data networks. By leveraging expertise, authority, and trust, a custom coaxial cable slicer empowers industries with the precision needed to excel in a rapidly evolving technological landscape, ensuring they remain at the forefront of innovation and efficiency.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy