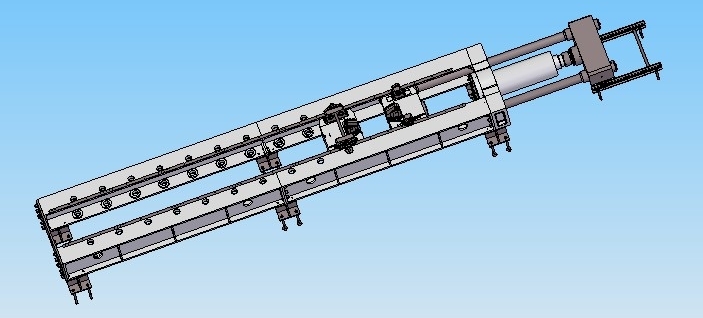

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Product Description

TXWL-600 electro-hydraulic servo horizontal tensile testing machine adopts horizontal frame structure, single rod double-acting piston cylinder exerts test force, and the computer control system realizes the automatic control of the test process by controlling servo valve and other components, the test data is accurately collected by load sensor and transmitted to the computer, the system automatically analyzes, processes and stores the test results, and the printer can directly print the required test report. This machine is mainly used for the tensile test of steel wire rope, is a modern production of scientific research and teaching and other industries to meet the requirements of the ideal test equipment.

Machine Description

1.Host system

The main machine part is mainly composed of main machine frame, oil cylinder seat, oil cylinder, moving beam, front and rear chuck seat and load sensor. It can carry out tensile test with a maximum load of 600kN on the sample.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

The test area is equipped with a protective cover, which can effectively protect the safety of test personnel.

2.Oil source system

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Electrical Section

The electrical control is arranged in the test operation area, and there is a specially designed operation panel to make all kinds of operations clear at a glance. The electric components are of international famous brand, with stable performance and reliable quality.

Software System:

(1) Based on the Windows XP operating platform with programmable functions, equal-rate test force control, equal-rate displacement control, test force holding, displacement holding and other test modes can be combined at will to meet the requirements of various test methods to the maximum extent, and to realize the various data display, curve drawing, data processing, storage and printing functions required for the test.

(2) Send a control signal to the servo valve through the computer to control the opening and direction of the servo valve, thereby controlling the flow into the cylinder, and realizing the control of equal-rate test force, equal-rate displacement, etc.

(3) Equipped with two closed-loop control loops of test force and displacement.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) The main interface has all the functions of the daily operation of the test, such as sample information entry, sample selection, curve drawing, data display, data processing, data analysis, test operation, etc. The test operation is simple and fast.

(6) The data can be output to the printer to print the test report.

(7) System hierarchical management, system parameters are all open to expert users, ensuring the flexibility and reliability of the system.

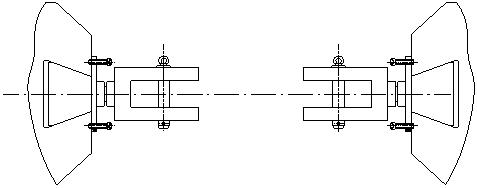

4.Test Accessories

Equipped with wire rope test accessories (see below) and other accessories are manufactured according to the standard provided by the user or the tensile requirements of the sample.

5.Safety Protection Devices

(1) Overload protection when the test force exceeds 2% to 5% of the maximum test force or the set value.

(2) Stroke protection when the piston moves to the limit position.

(3) With oil temperature, liquid level and oil resistance protection and indication devices.

(4) The test space has a protective cover to prevent the sample from breaking and falling out.

(5) When an emergency occurs, press the emergency stop button on the control cabinet directly

Technical Parameter

1.Maximum test force: 600kN

2.Test force measurement range: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensile test space (excluding piston stroke): 20mm ~ 12000mm

5.Piston stroke: 1000mm

6.Maximum working speed of the piston: 100 mm/min

7.Deformation extensometer accuracy: 0.01mm

8.The dimension of the main machine(mm): 16000(L) x 1300(W) x 1000(H) (excluding the protective cover)