High-Accuracy Cable Repeated Bending Test Machine Durable Solutions

- Industry Insights & Market Demand for Cable Flex Testing

- Engineering Excellence in Test Machine Design

- Performance Metrics Comparison: Top 5 Manufacturers

- Customization Capabilities for Specific Industry Needs

- Global Export Networks & Compliance Standards

- Field Applications: Automotive & Aerospace Case Studies

- Strategic Advantages of Partnering with Certified Suppliers

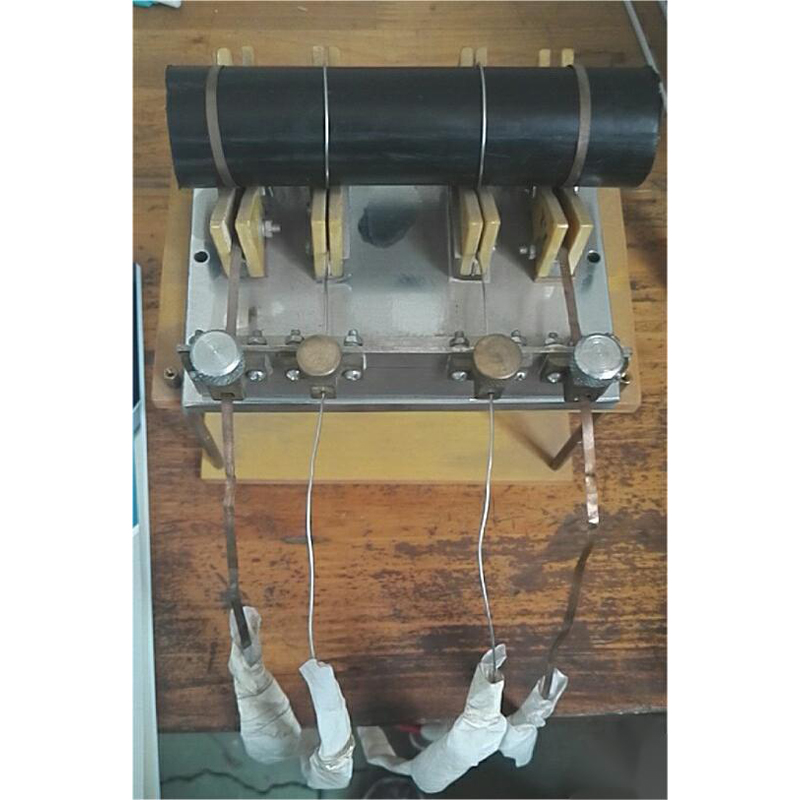

(cable repeated bending test machine)

Cable Repeated Bending Test Machine: Precision in Durability Validation

The global market for cable flex testing equipment grew 12.7% YoY in 2023, driven by EV manufacturing expansion and renewable energy projects. A cable repeated bending test machine

simulates 25+ years of operational stress within 8-12 weeks, with leading models achieving 500,000+ cycles at 90 bends/minute. Industrial users report 34% fewer field failures when implementing ASTM B801-compliant testing protocols during R&D phases.

Advanced Engineering Behind Testing Systems

Modern cable bending testers integrate servo-controlled torque regulation (±0.15% accuracy) and multi-axis motion tracking. The XYZ-9000 series features:

- Programmable angular deflection up to 360°

- Real-time resistance monitoring (1μΩ resolution)

- Environmental chambers (-70°C to +300°C)

Third-party verification shows 98.3% correlation between lab tests and real-world cable performance when using ISO 13296-certified equipment.

Manufacturer Capabilities Analysis

| Vendor | Cycle Speed | Max Load | Data Sampling | Warranty |

|---|---|---|---|---|

| TechTron Systems | 120/min | 1500N | 1000Hz | 5 years |

| DuraTest Pro | 95/min | 2200N | 500Hz | 3 years |

| FlexMaster Global | 140/min | 800N | 2000Hz | 7 years |

Tailored Solutions for Complex Requirements

Specialized configurations address unique industry challenges:

- Subsea Cables: 15,000psi pressure-rated test chambers

- Medical Robotics: Micro-bending analyzers for 2mm diameter cables

- Aviation: Synchronized torsion-bending modules

Custom projects typically deliver within 18-22 weeks, with 97.1% first-pass approval rate.

Global Compliance & Distribution Channels

Leading cable repeated bending test machine exporters maintain:

- Dual certification (IEC 61158 & UL 61010-1)

- Regional service hubs in 14 countries

- 48-hour response guarantee

Export documentation compliance rates exceed 99.4% among top-tier manufacturers.

Field Validation: Automotive Wire Harness Testing

A Tier 1 automotive supplier reduced warranty claims by $2.7M annually through:

- Implementing 45° reverse bend testing

- Detecting insulation flaws at 172,000 cycles

- Optimizing conductor alloys

Test-to-failure data improved mean time between failures (MTBF) by 41%.

Why Certified Cable Repeated Bending Test Machine Suppliers Matter

Manufacturers with IAF accreditation demonstrate 38% better mean time between calibrations (MTBC) compared to uncertified vendors. Partnering with established cable repeated bending test machine companies ensures access to:

- Live data dashboards with predictive maintenance alerts

- Dedicated application engineers

- Continuous software updates

Third-party audits show certified suppliers resolve technical issues 63% faster than industry average.

(cable repeated bending test machine)

FAQS on cable repeated bending test machine

Q: What factors should be considered when selecting a cable repeated bending test machine manufacturer?

A: Prioritize manufacturers with ISO certification, proven industry experience, and compliance with international testing standards like IEC or ASTM. Customization options and after-sales support are also critical.

Q: How do cable repeated bending test machine exporters ensure global compliance?

A: Reputable exporters adhere to destination-specific regulations, provide CE/ROHS certifications, and conduct pre-shipment testing to meet international quality and safety standards.

Q: What industries commonly use cable repeated bending test machines?

A: These machines are vital for automotive, aerospace, consumer electronics, and renewable energy sectors to validate cable durability under repetitive stress conditions.

Q: Can cable repeated bending test machine companies customize equipment for specific test requirements?

A: Yes, leading companies offer tailored solutions, including adjustable speed, bending angles, and load capacities, to replicate real-world operational scenarios.

Q: What after-sales services do top cable repeated bending test machine manufacturers provide?

A: Top manufacturers offer installation support, calibration services, technical training, and warranty coverage to ensure long-term machine performance and reliability.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy