फेब्रुवारी . 04, 2025 01:34

Back to list

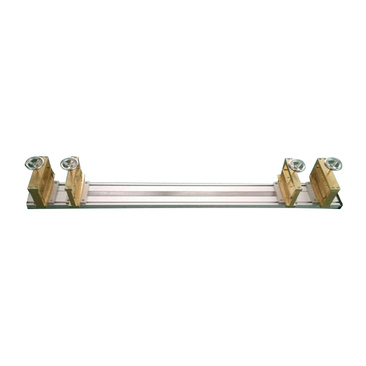

custom cable combustion testing machine

The demand for custom cable combustion testing machines is surging, driven by the imperative to ensure safety in electrical and data transmission environments. This niche yet critical domain requires expertise, precision, and reliability—features that are integral to distinguishing the best in the field. Let’s delve into why investing in a high-quality custom cable combustion testing machine constitutes a strategic advantage for any business operating in cable manufacturing, electrical transport, or safety equipment.

Trustworthiness in test data is paramount, especially when public safety is at stake. It’s critical to select machines that are tried and tested, built with components that meet global standards. This ensures not only high performance but also durability and low maintenance costs. Manufacturers that blend innovation with reliability in their machines make sure each unit undergoes extensive trials before being deemed ready for the market, a testament to their authoritative stance in the industry. A significant advantage of custom solutions is the ability to future-proof operations. Industries evolve, regulatory requirements change, and new materials come into play. A customizable combustion testing machine allows businesses to adapt swiftly without overhauling their testing infrastructure. Modular designs, upgradable software, and scalable hardware options mean that as your testing needs evolve, your machine evolves with it. The most respected names in cable combustion testing employ a suite of quality controls that start from prototype development to after-sales service. Their expertise is not only reflected in their products but also in the training and support services they offer. Educating the client on operational best practices, understanding complex test data, and leveraging these insights for product enhancement create a comprehensive user experience that fosters long-term business relationships. The experience of incorporating such a machine into a business process does not end at purchase. Continuous innovation, feedback mechanisms, and service maintenance play crucial roles in ensuring the technology remains at the forefront of industry standards. As innovations emerge, manufacturers committed to excellence update their designs to incorporate the latest predictive technologies and smarter algorithms, thus remaining an authoritative source in a rapidly advancing field. In conclusion, investing in a custom cable combustion testing machine is not merely about meeting current testing needs—it is a forward-thinking strategy essential for future-proofing your business. Ensuring experience, expertise, authoritativeness, and trustworthiness in your selection will return dividends not just in compliance, but in securing a reputation for quality and reliability. For any organization devoted to producing cables that sustain and protect lives, choosing the right testing tool is paramount. It is a decision that speaks to the core commitment of quality and safety in the manufacturing world.

Trustworthiness in test data is paramount, especially when public safety is at stake. It’s critical to select machines that are tried and tested, built with components that meet global standards. This ensures not only high performance but also durability and low maintenance costs. Manufacturers that blend innovation with reliability in their machines make sure each unit undergoes extensive trials before being deemed ready for the market, a testament to their authoritative stance in the industry. A significant advantage of custom solutions is the ability to future-proof operations. Industries evolve, regulatory requirements change, and new materials come into play. A customizable combustion testing machine allows businesses to adapt swiftly without overhauling their testing infrastructure. Modular designs, upgradable software, and scalable hardware options mean that as your testing needs evolve, your machine evolves with it. The most respected names in cable combustion testing employ a suite of quality controls that start from prototype development to after-sales service. Their expertise is not only reflected in their products but also in the training and support services they offer. Educating the client on operational best practices, understanding complex test data, and leveraging these insights for product enhancement create a comprehensive user experience that fosters long-term business relationships. The experience of incorporating such a machine into a business process does not end at purchase. Continuous innovation, feedback mechanisms, and service maintenance play crucial roles in ensuring the technology remains at the forefront of industry standards. As innovations emerge, manufacturers committed to excellence update their designs to incorporate the latest predictive technologies and smarter algorithms, thus remaining an authoritative source in a rapidly advancing field. In conclusion, investing in a custom cable combustion testing machine is not merely about meeting current testing needs—it is a forward-thinking strategy essential for future-proofing your business. Ensuring experience, expertise, authoritativeness, and trustworthiness in your selection will return dividends not just in compliance, but in securing a reputation for quality and reliability. For any organization devoted to producing cables that sustain and protect lives, choosing the right testing tool is paramount. It is a decision that speaks to the core commitment of quality and safety in the manufacturing world.

Next:

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy