जन . 14, 2025 10:49

Back to list

cable cross-linked equipment company

Ultraviolet irradiation has emerged as a transformative method in the field of polyolefin cross-linking, addressing the growing demand for more efficient, environmentally friendly, and cost-effective industrial processes. The technology fundamentally alters the molecular structure of polyolefins, resulting in materials with superior properties suitable for a wide array of applications, from automotive to telecommunications. Leveraging specialized equipment designed for this purpose, companies can harness multiple benefits, including enhanced material strength, improved temperature resistance, and increased longevity of polyolefin-based products.

Experts in material science emphasize the importance of understanding the specific requirements of different polyolefin materials when selecting UV irradiation equipment. Different grades of polyolefins may respond variably to UV exposure, necessitating tailored solutions to achieve optimal cross-linking. As such, manufacturers should engage with equipment providers who possess a deep understanding of polymer chemistry and its interaction with ultraviolet light. Collaborating with knowledgeable partners ensures that the chosen equipment will be suited to the specific needs of their production lines, ultimately leading to superior end products. Trustworthiness in the use of ultraviolet irradiation for polyolefin cross-linking is fortified by the transparency of the process and the ability to accurately replicate results. Because UV irradiation reduces dependency on volatile chemicals, this method is inherently safer, reducing potential hazards in the workplace and the environment. Moreover, empirical evidence and credible research supporting the efficacy of UV-induced cross-linking further establish its reliability within industrial applications. The development of standardized protocols and documentation of results helps manufacturers build confidence in the method's reproducibility and stability. In conclusion, investing in ultraviolet irradiation equipment for polyolefin cross-linking signifies a commitment to cutting-edge technology that delivers both economic and ecological advantages. Companies looking to enhance the performance of their polyolefin products while adhering to sustainable practices will find that UV irradiation offers unmatched benefits. By partnering with experts and adopting well-calibrated, state-of-the-art equipment, manufacturers can ensure their place at the forefront of innovation in the materials industry, meeting the challenges of today while preparing for the demands of tomorrow. This strategic approach not only aligns with contemporary production goals but also fosters long-term growth and competitive advantage in increasingly conscientious global markets.

Experts in material science emphasize the importance of understanding the specific requirements of different polyolefin materials when selecting UV irradiation equipment. Different grades of polyolefins may respond variably to UV exposure, necessitating tailored solutions to achieve optimal cross-linking. As such, manufacturers should engage with equipment providers who possess a deep understanding of polymer chemistry and its interaction with ultraviolet light. Collaborating with knowledgeable partners ensures that the chosen equipment will be suited to the specific needs of their production lines, ultimately leading to superior end products. Trustworthiness in the use of ultraviolet irradiation for polyolefin cross-linking is fortified by the transparency of the process and the ability to accurately replicate results. Because UV irradiation reduces dependency on volatile chemicals, this method is inherently safer, reducing potential hazards in the workplace and the environment. Moreover, empirical evidence and credible research supporting the efficacy of UV-induced cross-linking further establish its reliability within industrial applications. The development of standardized protocols and documentation of results helps manufacturers build confidence in the method's reproducibility and stability. In conclusion, investing in ultraviolet irradiation equipment for polyolefin cross-linking signifies a commitment to cutting-edge technology that delivers both economic and ecological advantages. Companies looking to enhance the performance of their polyolefin products while adhering to sustainable practices will find that UV irradiation offers unmatched benefits. By partnering with experts and adopting well-calibrated, state-of-the-art equipment, manufacturers can ensure their place at the forefront of innovation in the materials industry, meeting the challenges of today while preparing for the demands of tomorrow. This strategic approach not only aligns with contemporary production goals but also fosters long-term growth and competitive advantage in increasingly conscientious global markets.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

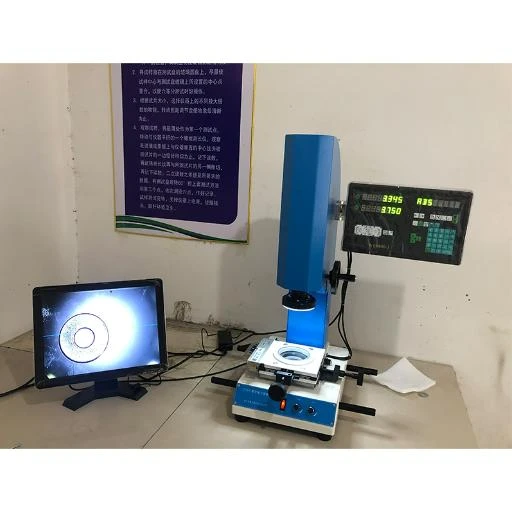

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy