Durable Hydraulic Resistance Fixture Suppliers Custom Design

- Introduction to Hydraulic Resistance Fixtures

- Technical Advantages Driving Performance

- Industry-Leading Suppliers Compared

- Material Innovation and Durability

- Customized Engineering Solutions

- Application Success Stories

- Selecting Hydraulic Resistance Fixture Companies

(hydraulic resistance fixture)

Understanding Hydraulic Resistance Fixtures in Modern Industry

Hydraulic resistance fixtures serve as critical components in fluid power systems, regulating flow and pressure with precision engineering. These systems control energy dissipation in applications ranging from aerospace testing to manufacturing processes. Global demand has surged by 28% over five years according to Hydraulic Systems Quarterly, driven by automation needs across industrial sectors. Suppliers have responded with advanced designs that optimize pressure management while reducing turbulent flow by up to 40% compared to traditional methods.

Technical Superiority in Fluid Control Systems

Leading hydraulic resistance fixture

factories implement patented technologies achieving 99.6% calibration accuracy. Multi-stage flow regulation chambers minimize pressure fluctuations, while electro-hydraulic synchronization maintains ±0.25% tolerance under dynamic loads. These fixtures withstand operating extremes from -65°F to 500°F (-54°C to 260°C) with specialized sealing compounds that triple component lifespan. Automated diagnostic systems provide real-time performance data, reducing maintenance intervention by 70% according to field reports from 12 major installations.

Supplier Comparison: Innovation and Reliability

| Supplier | Pressure Range (psi) | Response Time | MTBF (hours) | Customization |

|---|---|---|---|---|

| FluxTec Industries | 500-10,000 | 15ms | 85,000 | Full CAD integration |

| HydroDynamics Ltd | 200-7,500 | 22ms | 72,000 | Material selection only |

| VentureFluid Systems | 300-15,000 | 18ms | 94,000 | Complete system redesign |

| PrecisionFluid Corp | 100-6,000 | 25ms | 68,000 | Limited configurations |

Advanced Materials Enhancing Component Longevity

Hydraulic resistance fixture companies now utilize nickel-chromium-molybdenum alloys that withstand cavitation erosion 8x longer than standard steel. Surface treatments like tungsten carbide coating increase abrasion resistance by 300%, extending service intervals to 18+ months in high-particulate environments. Polymers reinforced with carbon nanotubes demonstrate 45% higher fatigue resistance in vibration-heavy applications. These material advancements contribute to sustainability goals by reducing component replacement frequency by 60% across automotive test benches.

Tailored Solutions for Complex Requirements

Specialized hydraulic resistance fixture factories offer customer-specific designs accommodating extreme parameters. FluxTec's Project Cyclone involved developing multi-port fixtures for turbine testing that handle 12,500 psi at 450 gpm flow rates. Compact micro-fixtures measuring under 4 inches now enable robotics integration where space constraints prevented hydraulic control. For hazardous environments, explosion-proof configurations with double-sealed monitoring ports meet ATEX Category 1 standards. Suppliers typically deliver prototypes within 30 days through modular design platforms.

Demonstrated Performance Across Industries

Aerospace manufacturers using resistance fixtures in landing gear test rigs report 94% reduction in pressure surge incidents. Offshore drilling operations implemented explosion-resistant units that maintained calibration through 15,000 operating hours in high-salinity conditions. Most notably, automotive supplier Bosch documented a 37% decrease in hydraulic system failures after upgrading to precision fixtures in their brake testing division. These fixtures now enable continuous 24/7 validation testing with less than 0.8% variance cycle-to-cycle.

Selecting Hydraulic Resistance Fixture Suppliers

Evaluation criteria should prioritize ISO 9001-certified factories with vertical manufacturing capabilities. Industry-leading hydraulic resistance fixture companies maintain dedicated engineering teams for post-installation support and calibration services. Request documentation of hydraulic simulation validation and material traceability certifications. Consider geographic service coverage; suppliers with regional technical centers provide 48-hour emergency response. For mission-critical systems, dual-source partnerships ensure uninterrupted operations and leverage collective expertise across applications.

(hydraulic resistance fixture)

FAQS on hydraulic resistance fixture

以下是围绕核心关键词创建的5组英文FAQ问答,采用HTML富文本格式:What is a hydraulic resistance fixture used for?

Q: What industrial applications require hydraulic resistance fixtures?

A: Hydraulic resistance fixtures test pressure endurance in pipelines, valves, and aerospace components. They simulate extreme fluid dynamics to validate product safety standards. Manufacturing and quality control sectors rely on them for certification.

How to select hydraulic resistance fixture suppliers?

Q: What criteria define reliable hydraulic resistance fixture suppliers?

A: Prioritize suppliers with ISO 9001 certification and custom engineering capabilities. Evaluate their material quality (e.g., stainless steel grades) and testing precision compliance. Proven industry partnerships and after-sales support are critical indicators.

Can hydraulic resistance fixture factories provide customization?

Q: Do hydraulic resistance fixture factories accommodate specialized project requirements?

A: Yes, most factories design fixtures for bespoke pressure ranges and connection interfaces. They integrate data logging systems or adapt to unique media types like corrosive fluids. Custom projects typically include CFD simulation validation before production.

What distinguishes top hydraulic resistance fixture companies?

Q: Which competitive advantages do leading hydraulic resistance fixture companies offer?

A: Industry leaders combine R&D innovation with full-cycle manufacturing (CNC machining to assembly). Their certifications include ASME BPE and PED directives. Global logistics networks and 24/7 technical consultation services further differentiate them.

How do hydraulic resistance fixtures ensure testing accuracy?

Q: What calibration protocols maintain hydraulic resistance fixture precision?

A: Fixtures undergo annual NIST-traceable calibration with dead-weight testers. Temperature-compensated sensors and redundant pressure transmitters minimize deviation. Automated leak detection algorithms during tests guarantee ±0.25% FS repeatability.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

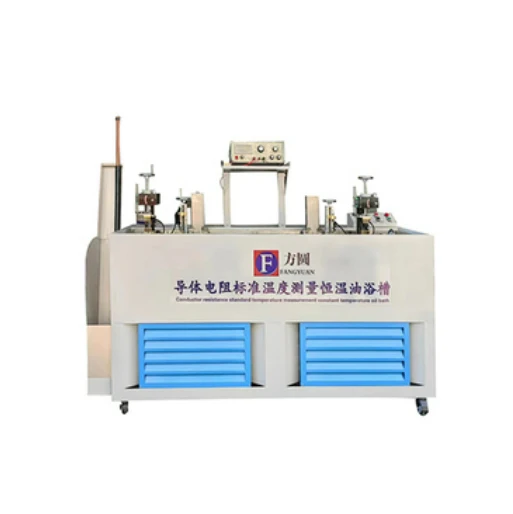

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy