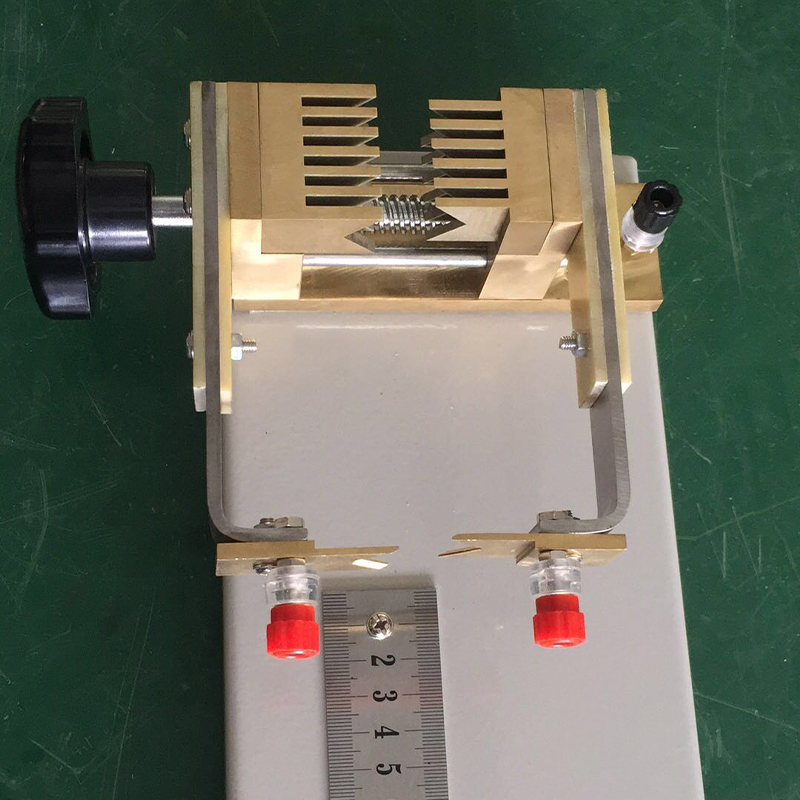

cable heat pressure test

Cable Heat Pressure Test Ensuring Reliability and Safety

The cable heat pressure test is a crucial procedure in the manufacturing and quality assurance of electrical cables used across various industries

. This test is designed to evaluate a cable's performance under extreme conditions, simulating real-world scenarios where heat and pressure might affect the integrity of the cable insulation and conductivity. The results of these tests are essential for ensuring that cables can withstand harsh environments without failure, thereby guaranteeing safety and reliability.During the cable heat pressure test, cables are subjected to elevated temperatures and internal pressures. Engineers carefully monitor the cable's response to these conditions, identifying any weaknesses or potential points of failure. The testing typically follows industry standards and regulations, which vary depending on the application of the cables, whether in residential, commercial, or industrial settings. By adhering to these standards, manufacturers can ensure their products meet the expectations of safety and longevity.

One key aspect of the heat pressure test is the examination of the cable’s insulation material. Insulation serves as a protective barrier against heat, moisture, and mechanical stress. By applying heat, testers can observe the behavior of the insulation under duress. If the insulation degrades or fails under high temperatures, the safety of the cable is compromised, potentially leading to electrical faults or fires. Therefore, the material's thermal stability is a critical consideration.

cable heat pressure test

Additionally, the impact of pressure on cable integrity cannot be ignored. Cables often traverse areas with varying environmental pressures, and understanding how they respond to such changes is vital. The test simulates these conditions, allowing inspectors to evaluate the durability of the cable’s sheath and core components. A successful heat pressure test will demonstrate that the cable can maintain its structural integrity, ensuring it provides reliable service over its expected lifespan.

Moreover, the results of these tests can influence product development and innovation. When manufacturers identify weaknesses in cable designs or materials during testing, they can refine their products to improve performance. This iterative process not only enhances the quality of the cables but also contributes to safer electrical systems overall.

In conclusion, the cable heat pressure test is an indispensable aspect of cable manufacturing and quality assurance. By rigorously evaluating how cables withstand heat and pressure, manufacturers can ensure their products meet essential safety standards and perform reliably under various conditions. This not only protects consumers but also builds trust in electrical infrastructure, making it a fundamental practice in the industry. As technology continues to evolve, the importance of such tests will only grow, fostering advancements that prioritize safety and efficiency.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy