Cable Heat Pressure Testing Services for Reliable Performance and Safety Standards

Cable Heat Pressure Test Ensuring Reliability and Safety in Electrical Systems

In today's fast-paced world, the importance of reliable electrical systems cannot be overstated. One of the critical components that contribute to the safety and efficiency of these systems is the cable used in electrical installations. With advancements in technology, the complexity of electrical systems has also increased, making it imperative for companies to conduct rigorous testing of their cables, particularly through cable heat pressure tests. This article explores the significance of cable heat pressure testing, the methodologies involved, and how companies can ensure the highest standards in reliability and safety.

Understanding Cable Heat Pressure Testing

Cable heat pressure testing is a crucial quality assurance process that evaluates the performance and safety of electrical cables under simulated conditions. This test aims to identify any potential weaknesses in the cable's insulation and construction before they lead to failures in real-world applications. The process typically involves subjecting cables to controlled thermal and pressure conditions, allowing engineers to observe how the materials react to extreme stress.

During the testing process, a sample of the cable is exposed to high temperatures while also being subjected to increased pressure. This combination simulates the real-life conditions that electrical cables may face, such as excessive heat generated by electrical currents or external pressure from the environment or installation conditions. By observing how cables respond to these stresses, engineers can evaluate their overall performance and longevity.

Importance of Cable Heat Pressure Testing

1. Safety Assurance Electrical failures can lead to catastrophic events, including fires and electrocution. By conducting heat pressure tests, companies can ensure that their cables are compliant with safety standards and free from defects that could cause failures during operation.

2. Quality Control Regular testing helps maintain high manufacturing standards, ensuring that only the best-quality cables reach the market. Companies that prioritize heat pressure testing demonstrate a commitment to quality, which can enhance their reputation and attract more customers.

3. Regulatory Compliance Various industry standards and regulations govern the quality of electrical cables. By conducting thorough heat pressure tests, companies can guarantee compliance with these regulations, which is crucial for legal and operational credibility.

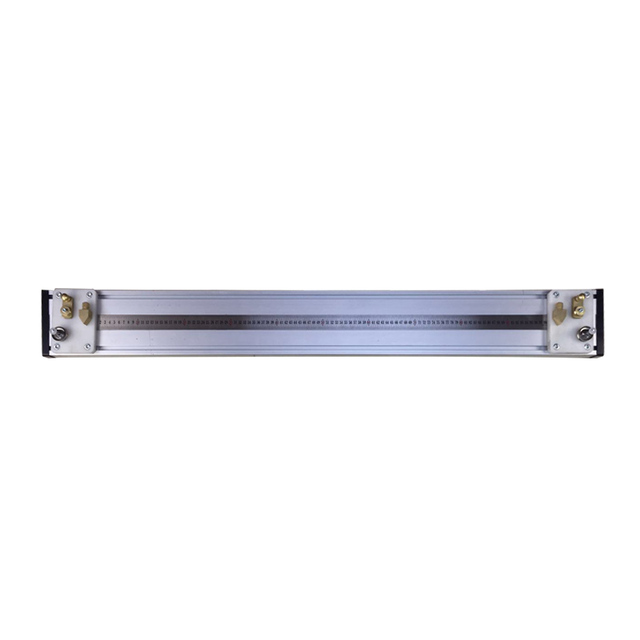

cable heat pressure test company

4. Cost Efficiency Identifying weaknesses in cables before they are installed can save companies significant costs associated with repairs, replacements, and potential legal liabilities due to accidents. Proactive testing minimizes the risk of failure, thus maximizing resource efficiency.

Methodologies of Cable Heat Pressure Testing

Cable heat pressure testing can be executed through different methodologies, depending on the specific requirements of the cable and the industry standards in place. Generally, it includes the following steps

1. Preparation Select the appropriate sample cables and prepare them for testing. This may include stripping insulation and ensuring proper connections to testing equipment.

2. Testing Environment Setup Establish a controlled environment where temperature and pressure can be accurately regulated. This may involve using specialized testing chambers designed to handle extreme conditions.

3. Testing Process Gradually increase the temperature and pressure while monitoring the cable's performance. Data is collected at various intervals to assess how the materials behave under stress.

4. Analysis and Reporting Once the testing is complete, the data is analyzed to identify any weaknesses or potential points of failure. A comprehensive report is generated, detailing the findings and recommendations for addressing any identified issues.

Conclusion

In conclusion, cable heat pressure testing is an indispensable part of ensuring the quality and safety of electrical cables. As technology evolves and electrical systems become more complex, the importance of rigorous testing will only grow. Companies committed to conducting thorough heat pressure tests not only enhance their product reliability but also contribute significantly to the safety and efficiency of electrical installations worldwide. By embracing best practices in cable testing, businesses can safeguard their operations and build trust with their customers, laying the groundwork for a safer electrical future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy