cable torsion testing machine factory

Cable Torsion Testing Machine Ensuring Safety and Durability in Cable Manufacturing

In the modern manufacturing landscape, quality assurance is paramount, especially when it comes to materials that play critical roles in engineering and construction. One such vital component is the cable, which is frequently used in various applications, from lifting and rigging to electrical transmission and infrastructure support. Ensuring the durability and reliability of cables under torsional stress is where a cable torsion testing machine comes into play. This article explores the importance, functioning, and production of cable torsion testing machines in factories.

Importance of Cable Torsion Testing

Cables are subjected to various forces during their service life. One of the most significant and potentially damaging types of stress is torsion. Torsion refers to the twisting force that can act on a cable, which may lead to material fatigue, failure, or even catastrophic accidents. As safety standards continue to rise across industries, manufacturers are placing greater emphasis on testing their products to meet rigorous safety and performance specifications.

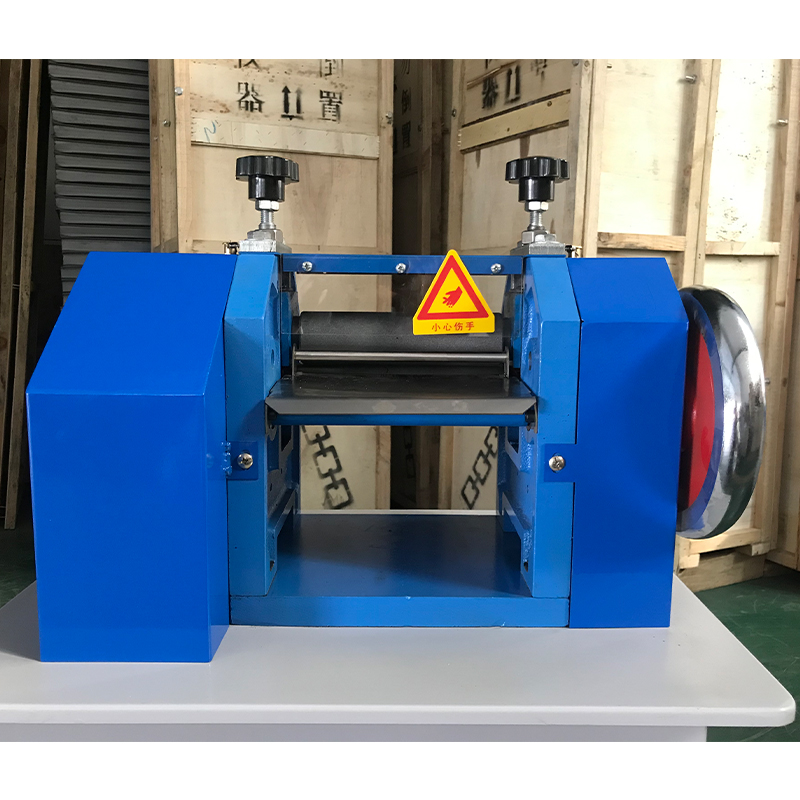

The cable torsion testing machine is specifically designed to evaluate the torsional strength and integrity of cables. It simulates the twisting forces that cables might encounter in real-world applications, allowing manufacturers to identify potential weaknesses in their products before they are distributed to the market.

Working of a Cable Torsion Testing Machine

A typical cable torsion testing machine consists of several essential components, including a torsion frame, torque sensor, controls, and a data acquisition system. Here's how it operates

1. Sample Preparation The cable sample is prepared according to predetermined dimensions and specifications. Proper preparation ensures that the test results are consistent and reliable.

2. Setup The cable is securely mounted between the jaws of the testing machine. The machine is calibrated according to the specific requirements of the test, ensuring accurate measurements.

3. Testing Process The testing machine applies a controlled torsional force to the cable. As the torsion is applied, the machine measures the angle of rotation and the torque being exerted on the cable.

cable torsion testing machine factory

4. Data Collection The machine collects data throughout the testing process. This information is vital for determining the cable's torsional properties, such as its yield strength, maximum torque capacity, and elasticity.

5. Analysis After completing the test, the collected data is analyzed to evaluate the performance of the cable. Manufacturers can then make informed decisions about design improvements or necessary adjustments to the production process.

Benefits of Cable Torsion Testing Machines

1. Quality Assurance By implementing rigorous testing standards, manufacturers can ensure that their cables meet industry regulations and safety requirements. This boosts consumer confidence and reduces liability for manufacturers.

2. Product Development The insights gained from torsion testing allow engineers to refine their designs, potentially leading to lighter, stronger, and more cost-effective cables.

3. Longevity and Reliability By identifying weaknesses in cable materials or construction, manufacturers can improve the longevity and reliability of their products, ultimately leading to safer applications.

4. Competitive Advantage Companies that invest in advanced testing technologies often gain a competitive edge in the market by demonstrating a commitment to quality and safety.

Conclusion

In the factory setting, the cable torsion testing machine stands as an indispensable tool for manufacturers striving to produce high-quality, reliable cables. By simulating real-world conditions and providing valuable insights into the torsional strength of materials, these machines help ensure that the cables not only meet safety standards but also exceed customer expectations. As industries continue to evolve and safety requirements become increasingly stringent, the role of cable torsion testing machines will remain critical in maintaining the standards necessary for structural integrity and public safety. As technology advances, we can expect further innovations in testing methodologies, leading to even more robust cable designs and enhanced manufacturing processes.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy