cable winding test machine companies

The Importance of Cable Winding Test Machines in Modern Industry

In the rapidly evolving landscape of modern manufacturing and engineering, ensuring the quality and reliability of cable products is paramount. Cable winding test machines play a crucial role in this process, providing manufacturers with the necessary tools to evaluate the performance and durability of cables under various conditions. As the demand for high-quality cables continues to rise, so does the significance of companies specializing in cable winding test machines.

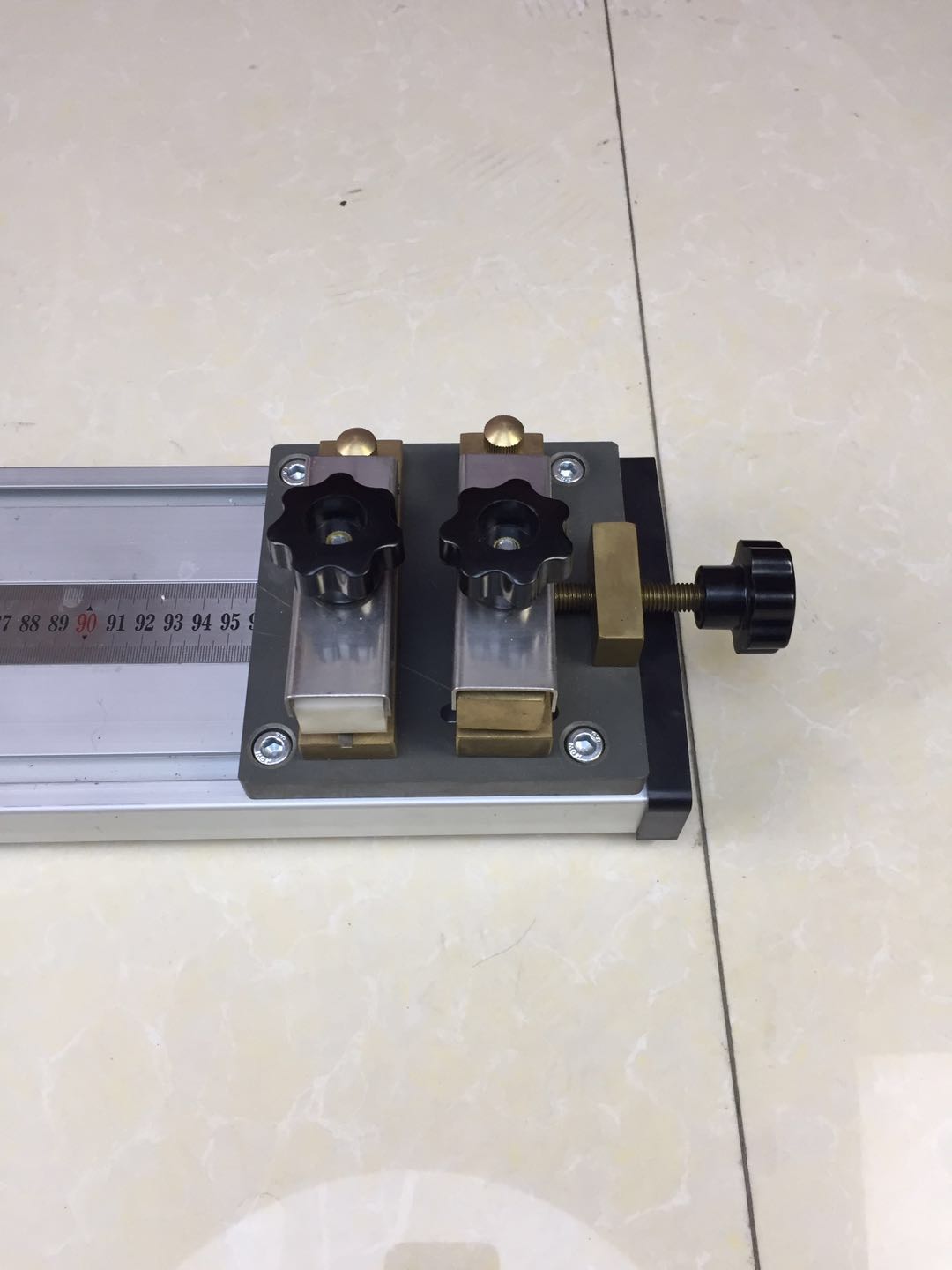

Understanding Cable Winding Test Machines

Cable winding test machines are specialized devices designed to simulate various environmental and operational conditions that cables may encounter during their lifespan. These machines are capable of performing a range of tests including winding tension, mechanical stress, and resistance to environmental factors like temperature and humidity. By utilizing these machines, manufacturers can ensure that their products meet industry standards and customer expectations.

Key Features of Cable Winding Test Machines

A typical cable winding test machine is equipped with several advanced features to facilitate comprehensive testing. Key features often include

1. Adjustable Tension Control This allows for testing cables under different levels of tension, simulating real-world applications where cables are subjected to varying loads.

2. Programmable Testing Cycles Many machines provide the ability to program specific testing sequences, allowing manufacturers to replicate various operational scenarios without manual intervention.

3. High Precision Measurement Test machines incorporate advanced sensors that offer accurate measurements of tension, elongation, and other critical parameters. This precision ensures that any faults or weaknesses in the cable can be identified and addressed early in the manufacturing process.

4. Data Logging and Reporting Modern machines are often equipped with software that logs test data and generates detailed reports. This feature not only aids in compliance with industry standards but also assists manufacturers in tracking performance over time.

cable winding test machine companies

The Role of Companies in the Market

With the increasing demand for reliable cables in sectors such as telecommunications, automotive, and power distribution, numerous companies have emerged that specialize in the production and supply of cable winding test machines. These companies vary in size and scope, ranging from small specialized manufacturers to large corporations with a global reach.

Leading companies in the sector prioritize research and development to create innovative solutions that enhance the efficiency and effectiveness of their testing machinery. They invest in cutting-edge technology, ensuring that their products can meet the dynamic needs of the industry. Furthermore, many of these companies offer tailored solutions, enabling manufacturers to customize testing parameters that align with their specific requirements.

Case Studies and Applications

Several industries benefit significantly from the use of cable winding test machines. For instance, in the telecommunications sector, high-speed fiber optic cables undergo rigorous testing to ensure their performance under various environmental conditions. Similar tests are conducted in the automotive industry, where cables must withstand extreme temperatures and mechanical stresses to meet safety standards.

One notable case involved a major automotive manufacturer that implemented a state-of-the-art cable winding test machine in its production line. By utilizing advanced tension control and data logging features, the manufacturer significantly reduced failure rates in its wiring systems. This not only improved product reliability but also enhanced customer satisfaction.

The Future of Cable Winding Test Machines

As technology continues to advance, the future of cable winding test machines looks promising. The integration of artificial intelligence (AI) and machine learning could revolutionize testing methods, enabling predictive maintenance and real-time quality assurance. Additionally, the growing emphasis on sustainability may lead manufacturers to develop more eco-friendly materials, necessitating the evolution of testing machines to accommodate new products.

In conclusion, cable winding test machines serve as a vital component in the quality assurance process of cable manufacturing. Companies engaged in the design and production of these machines are essential allies to manufacturers, helping them achieve high standards of quality and reliability. As industries continue to expand and evolve, the importance of rigorous testing and quality control will only grow, solidifying the role of cable winding test machines in the contemporary manufacturing environment.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy