Traditional Tensile Testing Methods in China for Material Strength Assessment

The Evolution of Traditional Tensile Testing in China

Tensile testing, an essential method for evaluating the mechanical properties of materials, has played a crucial role in various industries, particularly in the field of manufacturing and construction. In China, traditional tensile testers have been utilized for decades, embodying a rich history of materials testing and evolving technologies.

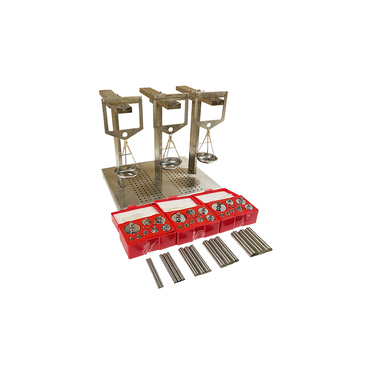

A traditional tensile tester primarily functions by applying a uniaxial force to a material specimen until it fractures. This process allows engineers and researchers to determine vital properties such as tensile strength, yield strength, elongation, and reduction of area. Historically, these testers were mechanical devices driven by hand, requiring significant skill and precision from the operator.

In China, the use of traditional tensile testers gained traction in the early 20th century. They were predominantly used in state-owned enterprises and laboratories to assess the quality of steel and other metals, which were essential for the nation’s rapid industrialization. The simplicity of design and the straightforward evaluation process made these devices quite popular among Chinese manufacturers. Technicians would often manually record measurements, relying on experience and intuition to interpret the results.

Despite their effectiveness, traditional tensile testers had their limitations. The manual operation often led to variations in test results due to human error, and the non-automated nature of the equipment meant that testing could be time-consuming and less efficient. However, the principles underlying tensile testing remained consistent, and the results gathered from these early tests laid the groundwork for modern advancements.

china a traditional tensile tester

As China accelerated its technological development in the late 20th and early 21st centuries, there was a significant shift towards automation and digitalization in tensile testing. This transition saw the introduction of computer-controlled tensile testers that could provide precise measurements and automated data analysis. The modern devices not only enhance accuracy but also improve the efficiency of testing processes. These advanced testers can conduct multiple tests simultaneously and generate detailed reports within minutes, a stark contrast to the labor-intensive processes of traditional methods.

Presently, while traditional tensile testers are still in use, particularly in smaller workshops and educational institutions, the industry is witnessing a blend of old and new technologies. Some manufacturers have incorporated elements of traditional testers into new designs, allowing for both manual and automated testing. This hybrid approach caters to diverse needs and preferences, ensuring that the rich heritage of traditional methods is not lost.

Moreover, the importance of tensile testing has extended beyond mere compliance. In contemporary contexts, it contributes significantly to research and development processes, innovation in material science, and sustainability efforts. The data gathered from tensile tests help engineers design safer structures and develop new materials with enhanced properties, thereby driving China's growth in various sectors.

Furthermore, as China integrates more deeply into the global market, adhering to international standards of tensile testing has become imperative. This has prompted the country to invest in advanced research initiatives and collaborations with leading global manufacturers of testing equipment, further enhancing the capabilities of its testing laboratories.

In conclusion, the journey of tensile testing in China reflects the broader narrative of industrial transformation and technological advancement. From traditional mechanical devices to state-of-the-art automated systems, the evolution of tensile testing illustrates the balance between preserving heritage and embracing innovation. As China continues to grow as a global manufacturing powerhouse, the importance of effective materials testing will remain a cornerstone of its industrial strategy, ensuring that quality and safety standards are met in an ever-competitive landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy