china conductor resistance test equipment

Understanding Conductor Resistance Test Equipment in China

Conductor resistance testing is a critical process in ensuring the reliability and safety of electrical systems. It helps to determine the resistance of conductors, thereby ensuring that they meet specified standards for efficient power transmission. In China, the demand for advanced conductor resistance test equipment has grown significantly due to the rapid expansion of the electrical and electronics industry, as well as stringent regulatory standards.

The Importance of Conductor Resistance Testing

Conductor resistance is a measure of how strongly a material opposes the flow of electric current. High resistance in conductors can lead to several issues, including overheating, voltage drops, and inefficient power distribution. Proper testing of conductor resistance is essential for

1. Ensuring Safety Faulty wiring can lead to short circuits or electrical fires. By testing resistance, potential hazards can be identified and mitigated.

2. Improving Efficiency Lower resistance indicates better conductivity. Ensuring that conductors are within recommended resistance levels optimizes energy efficiency in electrical systems.

3. Compliance with Standards Various national and international standards govern electrical testing. Using the right equipment ensures that companies comply, helping avoid potential legal issues and penalties.

Types of Conductor Resistance Test Equipment

The market in China offers a wide variety of conductor resistance test equipment, each designed for specific applications and environments. Some common types include

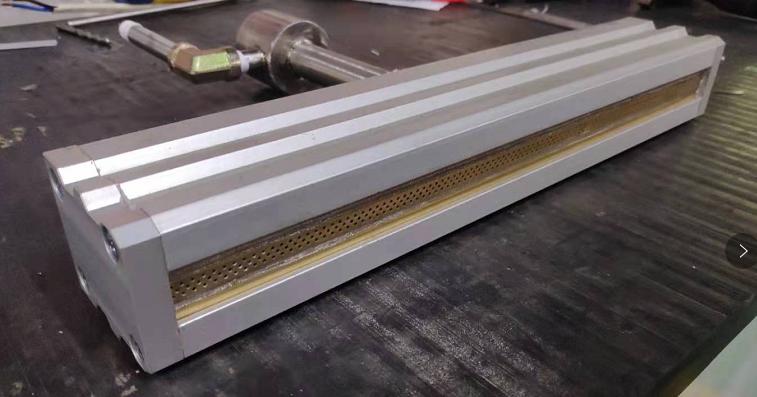

1. Micro-ohmmeters These are specialized devices used for measuring very low resistance values. They are essential for testing connections in high-voltage equipment and power transformers where precision is vital.

2. Resistance meters These are versatile instruments used for general conductor resistance testing. They measure resistance values across a broad range and are suitable for various applications in industrial and commercial settings.

china conductor resistance test equipment

3. Clamp-on ohmmeters These devices allow for non-intrusive measurements without disconnecting the circuit. They are especially useful for testing live circuits, providing convenience and safety to technicians.

4. Automatic resistance testers Advanced models automate the testing process, providing quick and accurate results. Features may include programmable test routines, data storage, and connectivity options for analysis.

Market Trends and Innovations

The conductor resistance test equipment market in China is witnessing several trends driven by technological advances and increasing demands for efficiency. Manufacturers are incorporating features such as

1. Digital Display and User Interfaces Modern test equipment often includes digital displays that provide clear, immediate readings and user-friendly interfaces for ease of operation.

2. Data Logging and Connectivity Many models now come equipped with capabilities to log test results and connect to computers or cloud services. This allows for better data management, analysis, and reporting.

3. Compact and Portable Designs As the need for testing grows, the market sees a trend towards lightweight, portable equipment that can be easily transported to various job sites, while still maintaining accuracy and reliability.

4. Smart Technology Integration The rise of IoT is influencing the development of test equipment with smart features. These devices can provide real-time data monitoring and alerts for immediate troubleshooting.

Conclusion

Conductor resistance test equipment plays an essential role in the electrical industry in China. As power transmission systems become more complex, and the demand for reliability increases, the need for efficient and accurate testing equipment becomes paramount. This has led to innovations in design, functionality, and ease of use. This evolution not only enhances the safety and efficiency of electrical systems but also ensures compliance with strict industry standards. As the industry continues to grow, the significance of conductor resistance testing will only become more pronounced, making the advancement of test equipment an essential focus for manufacturers and technicians alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy