china machine that tests tensile strength

Understanding Tensile Strength and the Machines That Test It

Tensile strength is a fundamental property in materials science, determining how materials respond to pulling or stretching forces. It measures a material’s ability to withstand tension without breaking. This property is critical in various industries, including construction, automotive, aerospace, and manufacturing, where materials must handle significant stress during use.

In recent years, China has made substantial advancements in the development of machines that test tensile strength. These machines are essential for ensuring that materials meet industry standards and are safe for consumer use. Testing the tensile strength involves applying a controlled force to a material until it fails, allowing engineers and scientists to analyze the material's performance under stress.

The Principle of Tensile Testing

Tensile testing typically involves the following steps

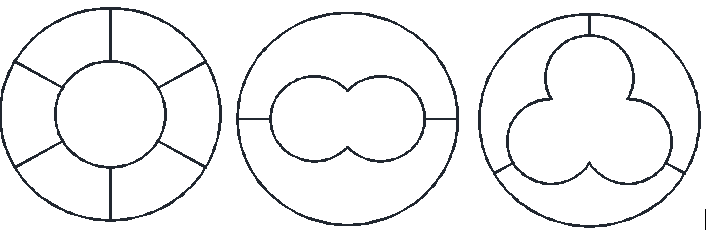

1. Sample Preparation Materials are cut into standardized shapes and sizes, often in the form of a dog-bone shape, which ensures uniform testing and accurate measurements.

2. Mounting the Sample The prepared sample is placed in the tensile testing machine, which consists of two grips. One grip is fixed, while the other is movable.

3. Applying Force The machine applies a tensile load to the sample steadily until it reaches its breaking point. Throughout the test, the machine measures the force applied and the elongation of the material.

4. Data Collection The data collected during the test is used to create a stress-strain curve, which provides insights into various material properties, such as yield strength, elongation, and ultimate tensile strength.

china machine that tests tensile strength

The Role of Testing Machines

China has developed a range of sophisticated tensile testing machines equipped with advanced technology. These machines often feature digital displays, automated load applications, and high-precision sensors for accurate measurements. Moreover, they are designed to comply with international testing standards, ensuring that materials are tested according to global criteria.

One notable aspect of Chinese tensile testing machines is their versatility. Many of these machines are capable of performing various tests beyond simple tensile strength measurements. They can evaluate compressive strength, flexural strength, and fatigue resistance, allowing manufacturers and researchers to obtain comprehensive data about the materials they are working with.

Industry Applications

The implications of tensile testing in China’s manufacturing sector are vast. Industries that rely heavily on robust materials, such as aerospace engineering, use tensile strength tests to ensure that components can withstand extreme conditions—pressure, temperature changes, and vibrations.

Automotive manufacturers also utilize these machines to maintain high safety standards. Every part in a vehicle must withstand considerable stress; therefore, understanding material properties through tensile testing is crucial in preventing failures that could endanger lives.

In the construction sector, tensile testing helps to guarantee the integrity of structural materials like steel and concrete. With the rapid infrastructure development in China, the demand for reliable testing equipment has surged, further highlighting the importance of these machines in maintaining safety and quality.

Conclusion

Tensile strength testing machines produced in China are at the forefront of materials testing technology. They play a crucial role in ensuring that various materials meet the high standards required across diverse industries. With continuous advancements in this field, these machines not only enhance material safety and reliability but also foster innovation within the manufacturing sector. As China continues to strengthen its position as a global leader in testing technology, the importance of tensile strength testing will remain a cornerstone for ensuring the quality and safety of materials used in everyday applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy