cross-linked cable slicer company

The Evolution and Importance of Cross-Linked Cable Slicers in the Modern Industry

In the ever-evolving landscape of technology and manufacturing, one area that has undergone significant advancements is the processing of cables. Particularly, cross-linked cable slicers have emerged as vital tools in the production and installation of high-performance cables. These machines are specifically designed to cut cross-linked polyethylene (XLPE) cables, which are widely used for their durability, heat resistance, and electrical insulation properties. As industries continue to strive for efficiency and quality, the importance of specialized equipment, such as cross-linked cable slicers, has become increasingly apparent.

Cross-linked polyethylene cables are found in various applications, ranging from power distribution to telecommunications. Their unique properties make them ideal for use in environments where extremes of temperature and humidity can be encountered. However, the manufacturing and handling of these cables require precise cutting techniques to ensure that the integrity of the cable is maintained. This is where cross-linked cable slicers come into play, offering exacting specifications to achieve clean cuts without compromising the cable’s structure.

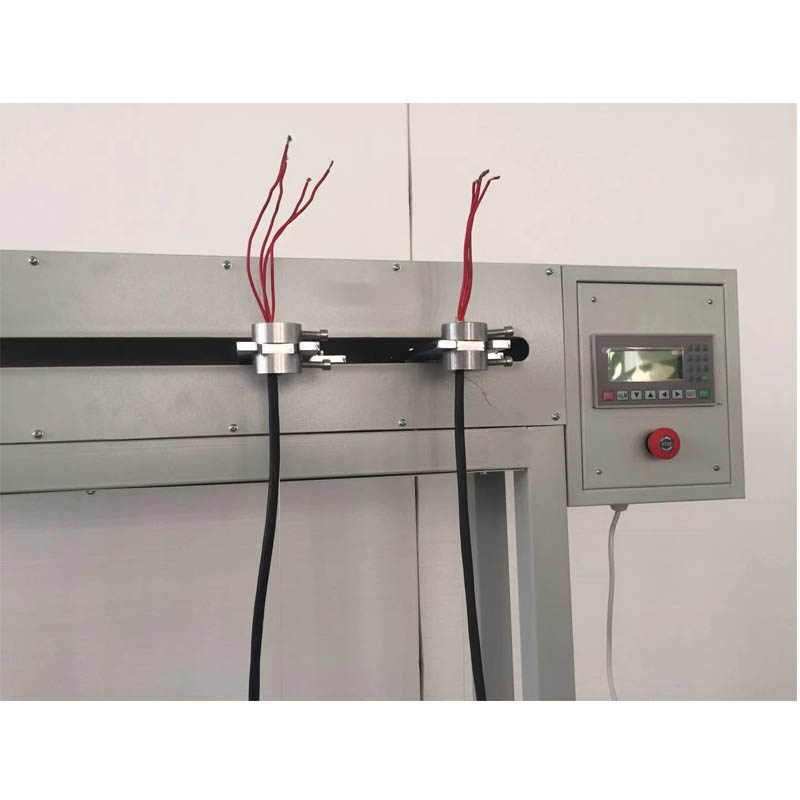

The advancement of cross-linked cable slicers can be attributed to the need for higher precision in production. Traditional cutting methods often lead to frayed edges and inconsistencies, which can compromise the performance of the cables. Advanced slicers utilize state-of-the-art technology, which includes programmable controls, automated feed mechanisms, and high-quality cutting blades. These features ensure a clean, accurate cut every time, thereby improving overall production efficiency and reducing waste. Furthermore, modern slicers are designed to handle a variety of cable sizes and types, making them adaptable to the diverse needs of manufacturers.

cross-linked cable slicer company

Safety is another paramount consideration in the operation of cross-linked cable slicers. The manufacturing environment can pose numerous risks, and ensuring the safety of operators is crucial. Contemporary slicers incorporate safety features such as emergency stop buttons, blade guards, and sensors that detect operator presence to prevent accidents. These innovations not only protect workers but also help in maintaining compliance with industry safety standards.

In addition to safety and efficiency, the environmental impact of manufacturing processes has become a focal point for many companies. Cross-linked cable slicers contribute to sustainability efforts by minimizing waste. The precision of these machines allows for optimal use of materials, reducing offcuts and ensuring that every portion of cable is utilized effectively.

In conclusion, the role of cross-linked cable slicers in modern manufacturing cannot be overstated. As the demand for high-quality, durable cables continues to grow, the need for advanced cutting technologies will likewise increase. These machines not only enhance the efficiency and safety of the production process but also support sustainability initiatives within the industry. As technology continues to advance, we can expect further innovations in cable processing equipment, paving the way for a future where manufacturing is not only effective but also environmentally responsible. The cross-linked cable slicer company stands at the forefront of this evolution, committed to delivering the precision and reliability that modern industries require.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy