Flat Cable Cutter Production Facility Overview and Key Features

Flat Cable Cutter Factory Meeting the Demand for Precision Cutting Tools

In the fast-paced world of modern manufacturing and electronics, precise and efficient cutting tools play a crucial role. Among these tools, flat cable cutters have emerged as essential devices for professionals in various fields, from telecommunications to automotive industries. With the increasing demand for high-quality flat cable cutters, the establishment of specialized flat cable cutter factories has become imperative. This article explores the significance of these factories, the manufacturing process, and their impact on the industry.

The Importance of Flat Cable Cutters

Flat cable cutters are designed to handle flat cables that are commonly used in electronic devices, networking setups, and wiring systems. Unlike traditional cutting tools that may damage the cables, flat cable cutters provide a clean and precise cut, ensuring the integrity of the cable and minimizing the risk of signal loss or other electrical issues. The growing reliance on technology in everyday life has led to an escalating demand for reliable cutting tools, making specialized factories essential.

The Manufacturing Process

Building a flat cable cutter factory involves several steps, from design and prototype development to mass production. The first stage is research and development, where engineers analyze market needs and design cutting tools that meet those specifications. This phase often includes creating prototypes to test cutting precision, ergonomics, and durability.

Once the design is finalized, the next step is the procurement of materials. The choice of materials is critical, as cutters must withstand repeated use while retaining sharpness and strength. Common materials for flat cable cutters include high-carbon steel or stainless steel, which provide both durability and resistance to corrosion.

After material sourcing, the manufacturing process begins. This involves cutting, shaping, and assembling the components of the cutter. Advanced technology is often employed to ensure precision during each stage of production. CNC (Computer Numerical Control) machines are commonly used to achieve exact specifications. The assembly process may include adding ergonomic handles, which enhance user comfort and reduce fatigue during extended use.

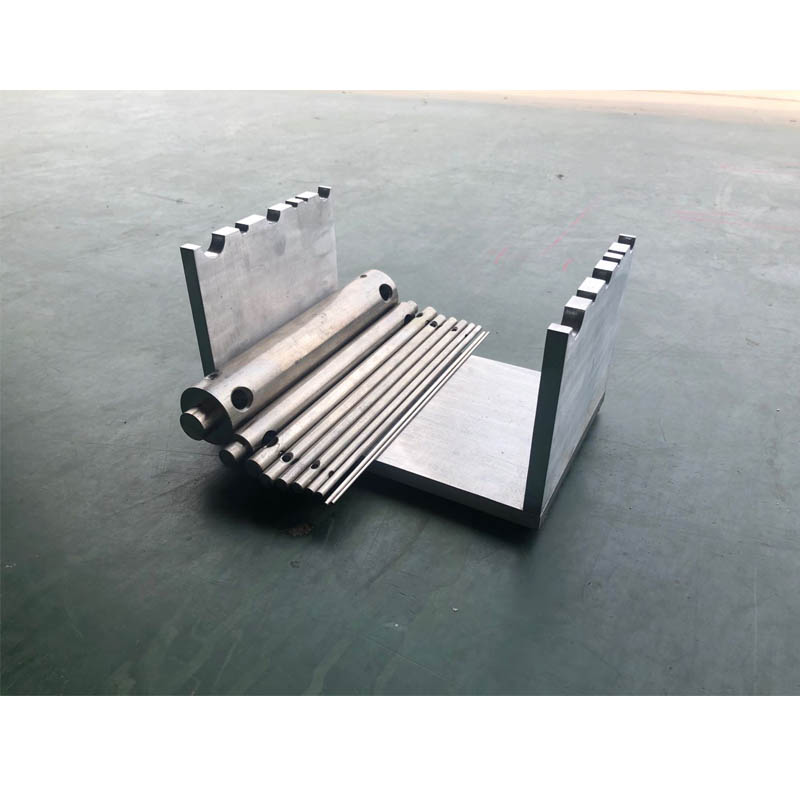

flat cable cutter factory

Quality control is a vital aspect of the manufacturing process. Each flat cable cutter is rigorously tested to ensure it meets safety standards and performs as expected. This process includes checking the cutting edge for sharpness, alignment, and overall functionality. By maintaining strict quality control measures, factories can produce reliable tools that professionals can trust.

The Impact on the Industry

The establishment of flat cable cutter factories has transformed the way cutting tools are manufactured and distributed. Local factories not only contribute to the economy by creating jobs but also reduce lead times for customers. With in-house production, manufacturers can quickly respond to market changes and meet the demand for customized tools.

Additionally, these factories often emphasize sustainability. Many are adopting eco-friendly practices, such as recycling scrap materials and utilizing energy-efficient machinery. This commitment to sustainability resonates with modern consumers, who increasingly prioritize environmentally responsible products.

Furthermore, the rise of flat cable cutter factories has led to innovations within the industry. Manufacturers are continuously seeking to enhance their products, leading to the development of advanced features such as self-sharpening blades, improved ergonomics, and multi-functionality. These innovations not only improve the user experience but also expand the potential applications of flat cable cutters across various industries.

Conclusion

As technology continues to evolve, so too does the need for precision cutting tools like flat cable cutters. The establishment of specialized factories dedicated to producing these tools has become essential in meeting this demand. Through innovative manufacturing processes, a commitment to quality, and a focus on sustainability, flat cable cutter factories are positioned to play a crucial role in the future of the industry.

For professionals in electronics, telecommunications, and other fields, investing in high-quality flat cable cutters from reputable factories ensures that they can perform their tasks with efficiency and precision. As we look to the future, these factories will undoubtedly continue to lead the way in providing the cutting-edge tools necessary to support the ever-changing landscape of technology.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy