tensile tester machine

Understanding Tensile Tester Machines Principles, Applications, and Significance

Tensile tester machines, also known as universal testing machines (UTMs), are essential instruments used in materials testing to measure the strength, elasticity, and elongation of various materials. These machines play a crucial role in a wide variety of industries, including construction, aerospace, automotive, and manufacturing, providing data that is vital for quality control, research, and development processes.

Principles of Operation

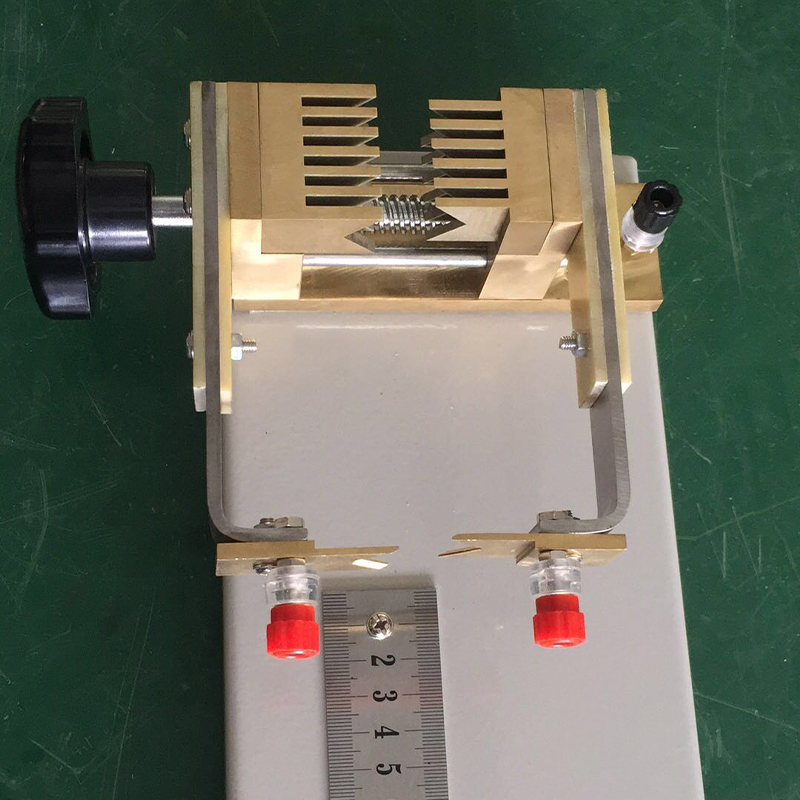

The basic principle of a tensile tester machine revolves around applying a controlled tensile force to a material specimen until it reaches its breaking point. The machine consists of several key components the load cell, specimen grips, a crosshead that moves at a controlled speed, and an electronic display system to record and analyze the data.

When a specimen is subjected to tensile stress, it experiences deformation. The tensile tester records several parameters, including the ultimate tensile strength (the maximum stress the material can withstand), yield strength (the stress at which a material begins to deform plastically), and elongation (the degree to which the material stretches before breaking). The data collected helps engineers understand the material’s behavior under stress and predict how it will perform in real-world applications.

Types of Materials Tested

Tensile tester machines are versatile and can test a wide range of materials including metals, polymers, composites, textiles, and more. Each of these materials responds differently to tensile stress; for instance, metals typically exhibit significant plastic deformation before breaking, while certain polymers might fail abruptly with little deformation.

Specific types of tensile tests can be performed depending on the material and the information required. For example, a tensile test on a steel specimen may focus on both the ultimate tensile strength and elongation to determine suitability for construction applications, whereas a textile tested may focus more on elongation and tensile strength to assess performance in wearable applications.

Importance in Industry

tensile tester machine

The significance of tensile tester machines cannot be overstated. In the construction industry, high-strength materials are crucial for ensuring the longevity and safety of structures. Tensile testing helps engineers choose the right materials for specific applications, whether it be beams, cables, or reinforcement bars.

Similarly, in the aerospace industry, tensile tests on materials used in aircraft components ensure they can withstand the significant forces experienced during flight. A failure in this context can have catastrophic consequences, making rigorous testing paramount.

In the automotive industry, tensile testing is vital for part manufacturing to enhance performance, safety, and compliance with regulatory standards. The strength and durability of materials used in vehicles directly affect performance and passenger safety.

Furthermore, in research and development, material scientists utilize tensile testers to develop new materials with tailored properties. Through experimentation and analysis, they can innovate by blending materials or altering compositions to achieve desired characteristics.

Advancements in Technology

The evolution of tensile tester machines has seen significant technological advancements. Modern machines feature computer-controlled systems that allow for precise control of testing parameters, leading to more accurate and repeatable results. The integration of software enables real-time data analysis, graphical representation of stress-strain curves, and automated reporting, facilitating quicker decision-making in laboratories and manufacturing plants.

Moreover, the rise of automation and robotics in material testing has improved efficiency and safety. Automated tensile testers can handle repetitive tasks without fatigue, ensuring consistent results while minimizing human error.

Conclusion

Tensile tester machines are invaluable tools across a multitude of sectors. Their ability to provide critical insights into the mechanical properties of materials ensures that products are safe, reliable, and high-performing. As industries continue to evolve and demand higher standards, the importance of tensile testing will only grow, solidifying the role of tensile tester machines as a cornerstone of materials science and engineering. In an ever-changing global landscape, the quest for innovation in material properties will rely heavily on the insights provided by these remarkable machines.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy